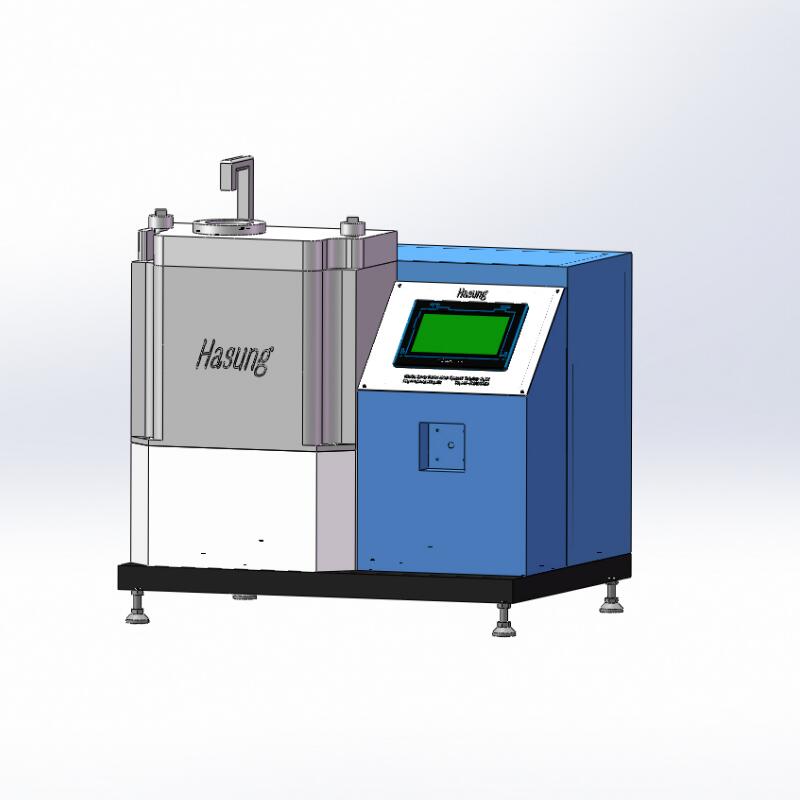

Imishini Yokusakaza I-Vacuum Pressure

Imishini yokukhipha i-HASUNG ifanele ukuncibilika nokuphonsa izinsimbi zokushisa okuphezulu okuncibilika. Ngokusho kwemodeli, bangaphonsa futhi bancibilike igolide, igolide leKarat, isiliva, ithusi, i-alloy ne-TVC, i-VPC, i-VC series, nensimbi, i-platinum, i-palladium ene-MC series.

Umqondo oyisisekelo wemishini yokukhipha i-vacuum vacuum ye-HASUNG ukuvala ikhava bese uqalisa ukushisisa uma umshini usugcwaliswe ngezinto zensimbi.

Izinga lokushisa lingakhethwa ngesandla.

Izinto ezincibilikisiwe ngaphansi kwegesi evikelayo (i-argon/nitrogen) ukuze kugwenywe i-oxidation. Inqubo yokuncibilika yayingabonwa kalula ngefasitela elibukayo. I-crucible ibekwe phakathi nendawo engxenyeni engaphezulu yegumbi le-aluminium elivaliwe eliqinile emoyeni kumongo we-spool yokungeniswa. Phakathi naleso sikhathi i-flask enefomu elivuthayo elivuthayo lifakwa engxenyeni engezansi yegumbi le-vacuum yensimbi engagqwali. Igumbi le-vacuum liyatsheka futhi lifakwe ngaphansi kwe-crucible. Ukuze inqubo yokuphonsa i-crucible isethwe ngaphansi kwengcindezi kanye ne-flask ngaphansi kwe-vacuum. Umehluko wengcindezi uholela insimbi ewuketshezi ibe yi-ramification enhle kakhulu yefomu. Ingcindezi edingekayo ingase isuke ku-0.1 Mpa iye ku-0.3 Mpa.

I-vacuum igwema ama-bubbles kanye ne-porosity.

Ngemva kwalokho i-vacuum room iyavulwa futhi i-flask ingakhishwa.

Imishini yochungechunge ye-TVC, VPC, VC ifakwe i-flask lift ephusha iflaski ibheke ku-caster. Lokhu kwenza ukususwa kweflask kube lula.

Imishini yochungechunge lwe-MC inyakazisa uhlobo lwe-vacuum casting, ene-90 degrees ephendukayo eklanyelwe ngokukhethekile ukukhishwa kwezinsimbi ezishisayo. Ithathe indawo ye-centrifugal casting.

-

I-VCT Series Vacuum Pressure Casting Machine ene-PLC Touch Screen

Umshini wokucindezela we-vacuum OLANDELAYO ka-Hasung umshini wakho olandelayo wokudala ikhwalithi.

1 I-flask yokusekela ene-flange ne-flask ngaphandle kwe-flange

2. Isivinini esihle sokuncibilika, ukonga amandla

3. I-Inert Gas - enezicucu ezinhle zokugcwalisa

4. Igeyiji enembile enenzwa yengcindezi ethuthukisiwe

5. Kulula ukuyigcina

6. Isikhathi esinembile sokucindezela

7. Ukuzihlola ngokwakho - I-Taiwan Weinview PLC iphaneli yokuthinta i-auto-tuning

8. Kulula ukusebenza, ibhodlela elilodwa ukuqeda yonke inqubo yokulingisa9. Ngemuva kwemodi ngaphandle kwe-oxidation

10. Ukushisa okuguquguqukayo kokulahlekelwa kwegolide

11. Ingcindezi ye-vacuum, ingcindezi ye-argon, izinga lokushisa, isikhathi sokuthulula, isikhathi sokucindezela, isikhathi se-vacuum.

-

VCTV Series Jewelry Vacuum Pressure Casting Machine With Vibration System

Umshini wokucindezela we-vacuum OLANDELAYO ka-Hasung umshini wakho olandelayo wokudala ikhwalithi.

1. Izindlela ezimbili ze-flask ene-flange ne-flask ngaphandle kwe-flange

2. Uhlelo lokudlidliza lokusakaza kahle

3. Ukuxuba okwengeziwe ukuze kuhlukaniswe kahle igolide

4. Isivinini esihle sokuncibilika, ukonga amandla

5. I-Inert Gas - enezicucu ezinhle zokugcwalisa

6. Igeyiji enembile enenzwa yengcindezi ethuthukisiwe

7. Kulula ukuyigcina

8. Isikhathi esinembile sokucindezela

9. Ukuzihlola wena - Japan Mitsubishi PLC iphaneli yokuthinta i-auto-tuning

10. Kulula ukusebenza, ibhodlela elilodwa ukuqeda yonke inqubo yokulingisa11. Ngemuva kwemodi ngaphandle kwe-oxidation

12. Ukushisa okuguquguqukayo kokulahlekelwa kwegolide

13. Ingcindezi ye-vacuum, ingcindezi ye-argon, izinga lokushisa, isikhathi sokuthulula, isikhathi sokucindezela, isikhathi se-vacuum, isikhathi sokudlidliza, isikhathi sokubamba ukudlidliza singasethwa, Uhlelo lwe-flask ene-flange, uhlelo lwe-flask ngaphandle kwe-flange, kokubili kuyatholakala, imodi ye-auto kanye nemodi yezandla. ayatholakala.

-

Umshini Wokusakaza we-TVC Series Induction Vacuum Pressure Casting we-Gold Silver Copper

Umshini Wokusakaza Ogcwele Ozenzakalelayo Wevacuum

Ubuchwepheshe obusha bokuthuthukisa imiphumela yokusakaza

I-Hasung Casting System

1.Ukuvala ikhava ngokuzenzakalelayo, konke kusebenza ngokuzenzakalelayo ekubumbeni ngokuvamile kuthuthukisa ukugeleza kwezinto kanye nokugcwaliswa kwesikhunta.

2.Ama-Castings akhombisa ukuminyana okuphezulu nokungaguquguquki

3.I-Porosity inciphe kakhulu

4. Melana noMax. 4 imigoqo ephonsa ingcindezi.

5. Isistimu yokusika ye-SBS ngaphandle kokusebenzisa ama-gaskets, yonga izindleko.

I-6.Castings inokucindezeleka okukhulu kanye nezakhiwo zokunwebeka, okwenza kube lula ukucubungula ngokuqhubekayo.

7. Ukusebenza okulula kokuthinta ngesikrini sepharamitha ewusizo

8. Izinhlelo eziyi-100 ezitholakalayo.

-

VPC Series Vacuum Pressure Casting Machine for Jewellery

Ingcindezi phezu kweMishini Yokusakaza Ngevacuum

I-VCT iwumndeni wengcindezi phezu kwemishini yokukhipha ivacuum eyenzelwe ukuhlangabezana nezidingo ezinzima kakhulu ekulahlekeni kokukhiqizwa kwe-wax yegolide, i-K-golide, ithusi, ithusi, ama-alloys. Zivame ukusetshenziswa ngokuxhumene nephrinta ye-3d ukuze kusakazwe ngokuqondile ukuze kutholwe izingxenye zensimbi zokuqala zezinto eziyinkimbinkimbi.

Lo mndeni wemishini usebenza nomqondo omusha wegumbi eliphindwe kabili. Lolu hlelo olusha lunikeza izinzuzo ezimbalwa uma kuqhathaniswa nesistimu yokudonsa yekamelo elilodwa etholakala manje emakethe.

Ku-VCT, ikamelo elincibilikayo negumbi le-flask alizimele ngokuphelele: ngenkathi uphonsa, umshini ungalawula umjovo wensimbi esikhunjeni ngokusebenzisa ingcindezi ehlukile ngesikhathi sokuthulula. Lokhu kuveza umjovo osheshayo uma kuqhathaniswa namandla adonsela phansi athela ngenzuzo yokuphonsa izinto ezingeni lokushisa eliphansi. Lokhu kuzoholela ekuqedeni okungcono kwendawo kanye nokuncipha kokuncipha kwezingxenye ezikhonjiwe.Umjikelezo wokuphonsa uthatha imizuzu embalwa kuphela futhi, ngenkathi i-flask yangaphambili iphola kugesi evikelayo ngaphandle kwe-oxidation, ukukhokhiswa okulandelayo kungalayishwa ku-crucible futhi kuncibilike, ngaleyo ndlela kudlule imijikelezo emibili ngaphandle kokumosha isikhathi.

Umshini uzenzakalela ngokugcwele, unesistimu yokuqapha esekelwe kwi-PC yokutholwa kwemingcele yenqubo nokuphathwa kwedatha yokukhiqiza, ngokuhlelwa kalula kwezinhlelo zokusakaza ezifanele izinhlobo eziningi ze-alloy.

Lo mshini wokuguquguquka uwukuhlanganiswa kobunjiniyela obuthuthuke kakhulu kanye neminyaka yesipiliyoni ekusakazeni okuzolethwa ngu-Hasung kuphela embonini yakho.

-

I-Hasung T2 Jewelry Vacuum Pressure Casting Machine

OKULANDELAYO umshini wokukhipha i-vacuum ka-Hasung ungumshini wakho olandelayo wokudala ikhwalithi.

Izinzuzo ze-T2:

1. Ngemuva kwemodi ngaphandle kwe-oxidation

2. Ukushisa okuguquguqukayo kokulahlekelwa kwegolide

3. Ukuxuba okwengeziwe ukuze kuhlukaniswe kahle igolide

4. Ijubane elihle lokuncibilika

5. I-De-Gas - enezicucu ezinhle zokugcwalisa izinsimbi

6. Igeji enenaliti enezinaliti ephindwe kabili enekhono lokuzwa ingcindezi

7. Kulula ukunakekela ngenkathi usakaza

8. Isikhathi esinembile sokucindezela

9. Ukuzihlolela wena - PID auto-tuning

10. Inkumbulo yepharamitha yokusakaza okuhle kakhulu

11. Isistimu Yokusakaza Isistimu yokukhipha ingcindezi ye-vacuum - ubuningi. ingcindezi engu-0.3MPa enethangi legesi langaphakathi

12. Ukushintsha iGas Single gas (Argon)

13. Inkumbulo Yohlelo Izinkumbulo eziyi-100

14. Lawula Isilawuli se-microprocessor esiklanywe ngokukhethekile. Ukulawulwa kwezinga lokushisa nge-PID ngokunemba kokuthi +/-1 degrees centigrade.

15. Ukushisa kwe-Induction Heating (okunomsebenzi oshukumisayo wensimbi oklanywe ngokukhethekile). -

I-Mini Vacuum Pressure Casting Machine ye-Platinum Palladium Steel Gold Silver

Izinzuzo ze-Hasung Precious Metals SVC/MC Equipment

Uchungechunge lwe-SVC/MC luyimishini yokulingisa esebenziseka ngezindlela eziningi elungele uhla olubanzi lwezicelo zokusakazwa kwensimbi - kanye nenani lezinketho ebezibhekwa njengezingahambelani kuze kube manje. Ngakho-ke, ngenkathi uchungechunge lwe-MC lwaqale lwaklanywa njengomshini wokuphonsa wezinga eliphezulu lokushisa kwensimbi, i-palladium, i-platinum njll (ubukhulu obungu-2,100 ° C), ama-flasks amakhulu nawo awenza afanelekele ukukhiqiza ngokwezomnotho ukukhishwa kwegolide, isiliva, ithusi, insimbi, ingxubevange nezinye izinto.

Umshini uhlanganisa isistimu yokucindezela okuhlukile kwamagumbi amabili kanye nomshini wokutshekisa. Inqubo yokulingisa ifinyelelwa ngokuzungezisa yonke iyunithi yokuncibilika ngo-90°. Enye inzuzo yesistimu yokutsheka ukusetshenziswa kwe-graphite enenani elingokomnotho noma izinsimbi ze-ceramic (ngaphandle kwezimbobo nezinduku zokuvala). Lezi zivame ukuba nempilo ende yesevisi. Amanye ama-alloys, afana ne-copper beryllium, abangela ngokushesha ama-crucibles anezimbobo nezinduku zokuvala ukuze angabonakali futhi ngenxa yalokho angenamsebenzi. Ngenxa yalesi sizathu, ama-casters amaningi kuze kube manje acubungule ama-alloys anjalo kuphela ezinhlelweni ezivulekile. Kodwa lokhu kusho ukuthi abakwazi ukukhetha ukwenza kahle inqubo ngokucindezela ngokweqile noma nge-vacuum.

-

Umshini Wokusakaza we-Vacuum Pressure Tilting we-Platinum Palladium Gold Silver Steel

Izinzuzo ze-Hasung Precious Metals Equipment

Umkhiqizo unombala ofanayo futhi akukho ukuhlukaniswa:

I-porosity iyancishiswa, futhi ukuminyana kuphakeme futhi akushintshi, kunciphisa umsebenzi wangemva kokucubungula futhi kunciphisa ukulahlekelwa.

Uketshezi olungcono lwempahla nokugcwalisa isikhunta, ingozi ephansi yentshiseko:

Ukudlidliza kuthuthukisa ukugeleza kwezinto, futhi ukwakheka kwezinto ezibonakalayo kuhlangene kakhulu. Thuthukisa ukugcwaliswa komumo futhi unciphise ingozi yokuqhekeka okushisayo

Usayizi wokusanhlamvu wehliselwa ku-50%:

Qinisa ngesakhiwo esicolekile nesifanayo

Izinto ezibonakalayo ezingcono nezime kakhulu:

Amandla okuqina nokunwebeka kukhuphuka ngo-25%, futhi ukusebenza kokucubungula okulandelayo kuyathuthukiswa.

Q: Ithini Indlela Yokukhipha Ivacuum?

Ukukhishwa kwe-investimenti, okuvame ukubizwa ngokuthi ukukhishwa kwe-wax elahlekile, izingxenye zensimbi ezikhiqizwa inqubo yokutshala izimali. Le nqubo yesikhunta esisebenziseka kalula kanye nezingxenye ezikhiqizayo idume kakhulu kwizicelo ezingenakubalwa ezimbonini eziningi. Lokhu kubangelwa kakhulu ukuthi inqubo yokufaka utshalomali yenza kube nokwenzeka ukudala izingxenye eziyinkimbinkimbi ezinezimfanelo ezivelele zangaphandle kanye nokunemba ezinhlobonhlobo zezinto namasayizi. Kodwa-ke, uma ingxenye idinga imininingwane eyinkimbinkimbi noma ama-undercuts, okokusebenza kuqiniswa ngefayibha noma ucingo, noma ukungena komoya kuyinkinga, kusetshenziswa uhlobo oluthile lwendlela yokutshala imali. Le nqubo yokufaka utshalomali ayiyona enye ngaphandle kwendlela yokukhipha i-vacuum, ekhiqize i-vacuum castings. Kuyini ukukhishwa kwe-vacuum? Qhubeka ufunda ukuze uthole.

Yiziphi i-Vacuum Investment Castings?

I-vacuum castings yizingxenye zensimbi ezikhiqizwa indlela yokukhipha i-vacuum. Ahlukile kunokulingwa okujwayelekile kokutshala imali ngenxa yesu elisetshenziselwa ukudala lezi zingxenye zensimbi. Inqubo iqala ngokubeka ucezu lwesikhunta se-plaster ekamelweni le-vacuum. Ivacuum ibe isidonsa insimbi encibilikisiwe esikhunjeni. Ekugcineni, ukubunjwa kuqiniswa kuhhavini futhi isikhunta siyasuswa ukuze kukhululwe umkhiqizo wokugcina.

Uma unephrojekthi edinga ukukhishwa kwe-vacuum yekhwalithi ephezulu yobucwebe noma ezinye izinsimbi, singakunikeza zona. Lapha kwa-Hasung, sisebenzisa kokubili izindlela zokuphakelwa kwamandla adonsela phansi kanye nezindlela zokukhipha i-vacuum ukukhiqiza igolide, isiliva, iplatinamu, izakhi zensimbi ezihlukene. Iminyaka yethu engenakubalwa yokuhlangenwe nakho kuzo zombili lezi zindlela iqinisekisa ukuthi singakwazi ukuhlinzeka ngezimo zenetha eziphakeme noma eziseduze ezidinga umsebenzi omncane noma ongaqediwe nhlobo. Thola ukulingisa kwe-investimenti okudingayo, kulethwe ngesikhathi nangenani elincintisanayo, ngokusithinta namuhla!

Q: Indlela yokuphonsa ubucwebe?

Ukubunjwa kobucwebe kuyinqubo yokwenza izingcezu zobucwebe ezibandakanya ukuthululwa kwengxube yensimbi ewuketshezi ibe isikhunta. Ngokuvamile kubizwa ngokuthi ukukhishwa kwe-wax elahlekile ngoba isikhunta sokubunjwa sidalwa kusetshenziswa imodeli ye-wax encibilikisiwe ukushiya igumbi elingenalutho phakathi kwesikhunta. Le nqubo isetshenziswe izinkulungwane zeminyaka, futhi isasetshenziswa kabanzi namuhla yibo bobabili abadwebi nabadwebi basekhaya ukwenza ukukhiqizwa okunembile kwezingcezu zobucwebe bangempela. Uma ungathanda ukudala ubucwebe bakho usebenzisa indlela yokulingisa, landela lezi zinyathelo zokuthi uphonsa kanjani ubucwebe.

1. Ukwakha Isikhunta Sakho

1) Baza ucezu lwe-wax oyimodeli eqinile ibe yisimo osifunayo. Qala kalula okwamanje, njengoba isikhunta esiyinkimbinkimbi sinzima kakhulu ukugcina ndawonye ekuqaleni. Thola ucezu lwe-wax oyimodeli futhi usebenzise ummese onembayo, i-Dremel, nanoma yiliphi elinye ithuluzi elidingekayo ukwenza imodeli yobucwebe bakho. Noma ngabe yimuphi umumo owenzayo manje uzoba yisimo sesiqephu sakho esiqediwe.

Wenza umfanekiso ofanayo wobucwebe bakho ekugcineni.

Ukusebenzisa ucezu lobucwebe obuthandayo njengemodeli kuzokusiza ukuklama izingcezu ezingcono uma uqala.

2) Namathisela 3-4 "sprues," izintambo ze-wax ezizohlinzeka ngomzila ukuze ingcina incibilike ngokuhamba kwesikhathi. Usebenzisa i-wax eyengeziwe, yenza izintambo eziningana ezinde, zikhiphe esikhumbeni bese uzinamathisela kumodeli ukuze zonke ziholele kude nocezu. Lokhu kulula ukukuqonda uma ubona yonke inqubo—le wax izombozwa ngokhonkolo, bese incibilika ukuze wenze inguqulo engenalutho yomumo wakho. Bese ugcwalisa ingxenye engenalutho ngesiliva. uma ungawenzi ama-sprues, ingcina encibilikisiwe ayikwazi ngempela ukuphuma futhi yenze indawo engenalutho.

Ezingxenyeni ezincane, njengendandatho, ungase udinge i-sprue eyodwa kuphela. Izingcezu ezinkulu, njengamabhande amabhande, zingadinga kufika eshumini.

Wonke ama-sprues kufanele ahlangane endaweni efanayo. Kuzodingeka zixhunywe kusisekelo se-sprue.

3) Namathisela isikhunta esisekelweni se-sprue usebenzisa irabha encane encibilikisiwe. Ama-sprue ahlangana ndawonye, bese unamathisela isikhunta esisekelweni se-sprue lapho kuhlangana khona wonke ama-sprues. Lokhu kuvumela i-wax ukuthi incibilike ngaphansi kwesisekelo futhi ishiye isikhunta.

4) Beka iflaski phezu kwesisekelo se-sprue, uqiniseke ukuthi une-intshi yesine phakathi kodonga lweflask kanye nemodeli. I-flask iyisilinda esikhulu esislayida phezu kwesisekelo se-sprue.

2. Ukutshala Isikhunta

1) Vikela imodeli ye-wax phansi kweflask yokuphonsa, usebenzisa i-wax encibilike kakhulu. Imodeli kufanele ibekwe phezu kwe-flask. Ilungele inqubo yokufaka ubucwebe.

Qaphela: Kuvidiyo, izingxenye zesiliva ezeqile ezinye izingcezu zobucwebe ezihambisana nebhande lebhande. Akuwona ama-sprues engeziwe noma izengezo ezidingekayo.

2) Hlanganisa izithako ezomile ze-gypsum plaster-based mold mold namanzi, ngokweziqondiso zomkhiqizi. Landela imiyalelo yanoma iyiphi isikhunta sokutshala imali okhetha ukusithenga—kufanele kube isethi elula yezilinganiso.

Gqoka isifihla-buso noma umshini wokuphefumula noma nini lapho kungenzeka njengoba usebenza nale powder—akuphephile ukuhogela.

Qhubeka uma usuyixube ukufana kwenhlama ye-pancake.

3) Beka isikhunta sokutshala imali ekamelweni le-vacuum ukuze ususe noma yimaphi amabhamuza omoya. Uma ungenayo i-vacuum sealer, ungayiyeka ihlale imizuzu eyi-10-20. Amabhamuza omoya azodala izimbobo, ezingase zivumele insimbi ukuthi ingene futhi yakhe isiqephu sokugcina sobucwebe esimakwe ngephakethe.

4) Thela ingxube yesikhunta sokutshala imali kufulaski, uzungeze imodeli ye-wax. Uzofaka ngokuphelele isikhunta sakho ku-plaster. Hlanza kabusha ingxube ukuze ukhiphe noma imaphi amabhamuza okugcina, amancane ngaphambi kokuthi uqhubeke.

Gcoba ungqimba lukampompi ngaphezulu kweflask, ukuze uhhafu wetheyiphu uhlale phezu kodebe futhi usize ukuqukatha ukhonkolo ukuze ungabhubhisi.

Vumela isikhunta sokutshala imali ukuthi simiswe. Landela imiyalelo eqondile kanye nesikhathi sokumisa sengxube yakho ye-plaster ngaphambi kokuqhubekela phambili. Uma usuqedile, susa itheyiphu futhi ukhuhle noma iyiphi i-plaster eyengeziwe ngaphezulu kwesikhunta.

5) Beka yonke flask kuhn omiswe cishe ku-1300 degrees F (600 degrees C). Qaphela, ama-plaster ahlukene angase abe namazinga okushisa ahlukene. Kodwa-ke, akufanele ube ngaphansi kwe-1100. Lokhu kuzoqinisa isikhunta futhi kuncibilikise i-wax, kushiye igumbi elingenalutho phakathi nendawo yokubunjwa kobucwebe be-cast.

Lokhu kungase kuthathe amahora angu-12.

Uma une-electronic kiln, zama ukuyisetha ukuthi inyuse kancane izinga lokushisa lifike ku-1300. Lokhu kungasiza ukuvimbela ukuqhekeka.

6) Khipha i-flask kuhhavini ngenkathi kushisa, futhi uhlole phansi kwesikhunta ukuze uthole izithiyo. Qinisekisa ukuthi i-wax eshisayo ingavuza kalula esikhunjeni, futhi akukho lutho oluyivimbelayo. Uma kungekho lutho endleleni, nyakazisa i-flask ngobumnene ukuze uqiniseke ukuthi yonke i-wax iphuma. Kufanele kube nechibi le-wax endaweni yokugcina i-flask noma phansi kuhhavini.

Qiniseka ukuthi ugqoka amagilavu okuphepha kanye nezibuko.

3. Ukuphonsa Ubucwebe

I-1) Beka insimbi yakho oyikhethayo esitsheni sokuthululela, bese uyincibilikisa ngaphakathi kwesisekelo. Izinga lokushisa lokuncibilika kanye nesikhathi kuzonqunywa uhlobo lwensimbi oyisebenzisayo. Ungasebenzisa futhi ithoshi elivuthayo kanye ne-crucible encane ukuze uncibilikise isiliva sakho. Lokhu ukusakaza kohlobo lokuthulula ngesandla ngenjongo yokukhiqiza encane.

2) Sebenzisa ukuphonsa kohlobo lwe-vacuum ye-vacuum (Umshini Wokukhipha I-Vacuum Pressure) ukuze uthele insimbi esikhunjini. Ngobucwebe obuchwepheshile, uzodinga umshini wokuphonsa wohlobo lwe-vacuum onegesi ye-inert ukuze uvikeleke. Lokhu kusabalalisa insimbi ngokulinganayo ngokushesha, kodwa akuyona ukuphela kwenketho onayo yokuphonsa. Isixazululo sakudala, esilula ukuvele uthele insimbi ngokucophelela emhubheni oshiywe yisisekelo sesikhunta.

Ungasebenzisa isirinji enkulu, eqondene nensimbi ukumpompa insimbi ekubunjweni kwayo.

3) Vumela insimbi ukuthi iphole imizuzu emi-5-10, bese uyicwilisa kancane emanzini abandayo. Isikhathi esidinga ukupholisa sincike, yiqiniso, ensimbi encibilikile futhi esetshenzisiwe. Dunk ngokushesha futhi insimbi ingase iqhekeke—iduke sekwephuze kakhulu futhi kuyoba nzima ukukhipha lonke ukhonkolo ensimbi eqinile.

Bheka izikhathi zokupholisa zensimbi yakho ngaphambi kokuthi uqhubeke. Sekushiwo lokho, uma ukupickle ungalinda nje imizuzu eyi-10 bese ucwilisa emanzini abandayo.

I-plaster kufanele iqale ukuncibilika njengoba uyinyakazisa emanzini abandayo.

4) Thepha isikhunta ngobumnene ngesando ukuze uphule noma yikuphi ukhonkolo owedlulele futhi uveze ubucwebe. Hlukanisa iflaski kusisekelo se-sprue futhi usebenzise iminwe yakho noma isixubho ukuze ususe noma yikuphi okokugcina okunamathele kubucwebe.

4. Ukuqeda Ubucwebe Bakho

1)Sebenzisa i-engeli grinder enesondo elisikiwe ukuze unqamule noma yimiphi imigqa yensimbi kuma-sprues. Sika izingcezu ezincane zensimbi obuzidinga ukuze udale imbobo ozothela kuyo insimbi. Igrinder ebanjwa ngesandla kufanele ibe namandla ngokwanele.

2)Cabangela nokugeza nge-asidi noma ukugeza ukuze uhlanze noma iyiphi ingxenye yokugcina yokhonkolo. Inqubo yokudubula ngokuvamile ishiya insimbi ingcolile futhi ibukeka ingcolile. Ungabheka izinto ezithile zokugeza izinsimbi ezithile, okuzoholela ekukhanyeni okuhle kanye nomsebenzi olula wokuhlanza ucezu kamuva.

3)Khipha noma yikuphi ukungahambi kahle ocezwini lobucwebe usebenzisa isondo lensimbi. Sebenzisa amafayela, izingubo zoqweqwe lwawo, ukupholisha, njll. ukuze uhlanze ucezu lube yisitayela osithandayo. Uma uhlele ukubeka itshe, kwenze ngemva kokuqeda ukupholisha.