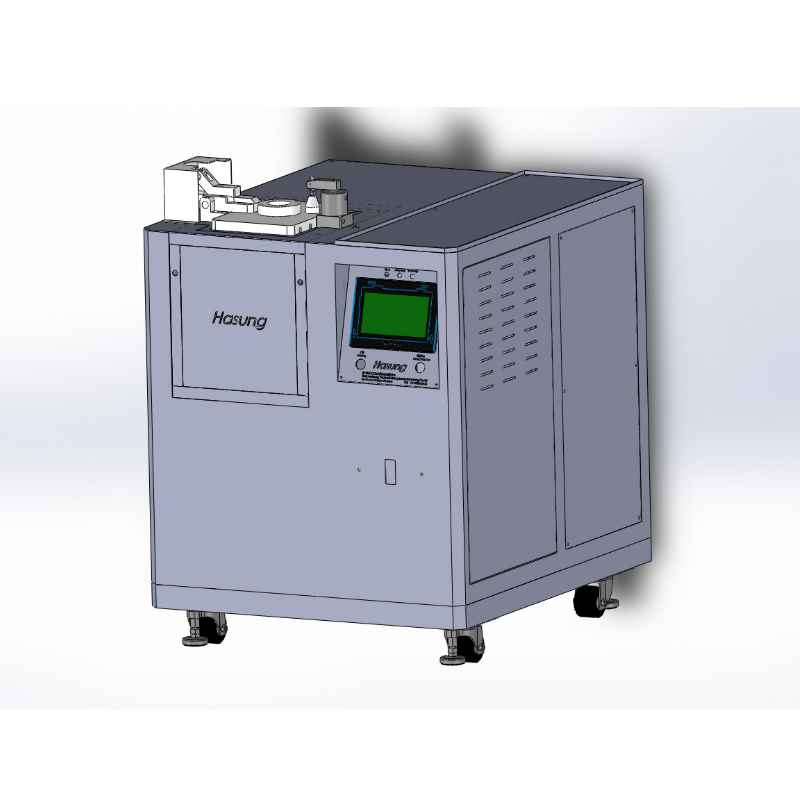

Umshini Wokusakaza we-TVC Series Induction Vacuum Pressure Casting we-Gold Silver Copper

Kungani Ukhetha Umshini Wokusakaza we-Hasung Vacuum Pressure?

Izici

Imishini yokusakaza ye-vacuum ye-Hasung iqhathaniswa nezinye izinkampani

Umshini wokusakaza uchungechunge lwe-TVC ungowokuqala esizukulwaneni sakamuva somshini wokukhipha i-pressure vacuum emakethe yomhlaba.Basebenzisa amajeneretha e-low-frequency, futhi ukulawulwa kwamandla kuyalingana futhi kulawulwa ngokuphelele yikhompyutha.Umsebenzisi umane abeke insimbi ku-crucible, abeke isilinda bese ecindezela inkinobho!Imodeli yochungechunge lwe-"TVC" iza nesikrini esithintwayo esinemibala engu-7 intshi.Kuyo yonke inqubo yokuhlanganisa, ukusebenza kwenzeka kancane kancane.

Inqubo ezenzakalelayo:

Uma ucindezela inkinobho ethi “Okuzenzakalelayo”, vacuum, igesi engasebenzi, ukushisisa, ukuhlanganisa kazibuthe okuqinile, vacuum, ukusakaza, , vacuum ngokucindezela, ukupholisa, zonke izinqubo ezenziwa imodi yokhiye owodwa.

Kungakhathalekile ukuthi hlobo luni nenani legolide, isiliva, ne-alloy, imvamisa namandla kuyashintshwa.Lapho insimbi encibilikisiwe ifinyelela izinga lokushisa lokusakaza, isistimu yekhompiyutha ilungisa ukushisisa futhi ikhiphe ama-low-frequency pulses ukuzwa ingxubevange enyakazayo.Lapho yonke imingcele ehleliwe ifinyelelwa futhi izinga lokushisa lizinza ekuphambukeni okukhulu ku-± 4 ° C, ukukhishwa kuqala ngokuzenzakalelayo, kulandelwa ukucindezela okunamandla kwensimbi ngegesi ye-inert.

Umshini wokusakaza uchungechunge lwe-TVC ungomunye osungula kakhulu esizukulwaneni sakamuva somshini wokukhipha i-pressure vacuum emakethe yomhlaba.

Basebenzisa amajeneretha e-low-frequency, futhi ukulawula kwamandla kuyalingana futhi kulawulwa ngokuphelele yikhompyutha.

Umsebenzisi umane abeke insimbi ku-crucible, abeke isilinda bese ecindezela inkinobho!I

Imodeli yochungechunge lwe-"TVC" iza nesikrini esithintwayo esinemibala engu-7 intshi.

Kuyo yonke inqubo yokuhlanganisa, ukusebenza kwenzeka kancane kancane.

Kungakhathalekile ukuthi hlobo luni nenani legolide, isiliva, ne-alloy, imvamisa namandla kuyashintshwa.

Lapho insimbi encibilikisiwe ifinyelela izinga lokushisa lokusakaza, isistimu yekhompyutha ilungisa ukushisisa futhi ikhiphe ama-pulse ane-low-frequency ukuzwa ingxubevange enyakazayo.

Lapho yonke imingcele ehleliwe ifinyelelwa futhi izinga lokushisa lizinza ekuphambukeni okukhulu ku-± 4 ° C, ukukhishwa kuqala ngokuzenzakalelayo, kulandelwa ukucindezela okunamandla kwensimbi ngegesi ye-inert.

Imingcele Yezobuchwepheshe

| Imodeli No. | I-HS-TVC1 | I-HS-TVC2 | I-HS-TVC4 | I-HS-TVC6 | I-HS-TVC8 |

| Amandla kagesi | 220V isigaba esisodwa / 380V 3 izigaba 50/60Hz | 380V 3 izigaba, 50/60Hz | |||

| Ukunikezwa kwamandla kagesi | 10KW | 15KW | 20KW | ||

| I-Max Temp | 1500°C | ||||

| Isikhathi Sokuncibilika | 2-3 amaminithi. | 3-5 imiz. | 3-5 min | 3-5 imiz. | 4-6 imiz. |

| I-Shielding Gas | I-Argon / i-nitrogen | ||||

| Ingcindezi | 0.1-0.3Mpa (Iyalungiseka) | ||||

| Ukunemba Kwesikhashana | ±1°C | ||||

| Amandla (Igolide) | 1kg | 2kg | 4kg | 6kg | 8kg (Igolide) |

| Ubukhulu.Usayizi weflask | 4"x10" / 5"x12" | 5"x12"/6.3"x12" | 6.3"x12" | 8.6"x12" / 10"x13" | |

| Iphampu yeVacuum | Iphampu yevacuum yekhwalithi ephezulu/iphampu yesivacu yaseJalimane, idigri yevacuum - 100KPA (uma uthanda) | ||||

| Isicelo | Igolide, i-K igolide, isiliva, ithusi namanye ama-alloys | ||||

| Indlela yokusebenza | Ukusebenza kokhiye owodwa ukuqedela yonke inqubo, uhlelo lwe-POKA YOKE olungenangqondo | ||||

| Uhlobo lokupholisa | I-water chiller (ithengiswa ngokwehlukana) noma Amanzi agijimayo | ||||

| Ubukhulu | 680*880*1230mm | ||||

| Isisindo | cishe.150kg | cishe.150kg | cishe.160kg | cishe.180kg | cishe.250kg |

Isibonisi somkhiqizo

Izindlela zokusakaza

Izindlela ezijwayelekile zokulingisa yilezi:

ukukhanya kwelangabi

ukukhishwa kwe-induction

i-vacuum pressure die-casting

Ukusakaza amalangabi

Ukukhipha amalangabi kuyindlela evamile kakhulu yokulingisa futhi cishe iyona evame kakhulu futhi engabizi kakhulu.Le ndlela ibe usizo ekuthuthukiseni amasu okulingisa kodwa ayihambisani kahle nezidingo zomthetho nezobuchwepheshe zemakethe yanamuhla.Le nqubo isekelwe kuphela emandleni nekhono lomsebenzisi: ukusebenzisa le nqubo kudinga ikhono lokulawula ilangabi, ulwazi oluhle lokusebenza kwensimbi kanye nokuzwela nokusebenza ngokucophelela. Nakuba kuyiqiniso ukuthi o-opharetha abaningi bangongcweti bangempela bale nqubo thina. cabanga ukuthi le nqubo ngeke iqinisekise ukukhiqizwa kabusha kanye nezinga lekhwalithi eliqhubekayo.Futhi uma inqubo, efana nale, isekelwe ngokuphelele ekhonweni nekhono lomsebenzisi akuyona inqubo eguquguqukayo, futhi ukuguquguquka kuyisidingo esibalulekile kumalabhorethri ochwepheshe bamazinyo besimanje.Inqubo kufanele, ngempela, ikwazi ukuphinda ikhiqizeke ngaphandle kokunaka ikhono labasebenzisi.Ngaphezu kwalokhu indlela yokukhipha amalangabi ayikuvumeli ukuqinisekiswa nokubhalwa kwenqubo yokuphonsa ngezinhlelo zokulawula inqubo ezizenzakalelayo.

Ukulingisa kokungeniswa

I-Induction casting kumelele impumelelo emkhakheni wokulingisa kodwa naphezu kwalokhu le nqubo inezici ezithile ezenza kungenzeki ukuyisebenzisa ngendlela enengqondo nehlelekile elabhorethri yochwepheshe bamazinyo.Uhlelo lokungeniswa luyi-semi-automatic ngokwemvelo futhi lonke. inqubo, njengokusakazwa kwelangabi, incike ekhonweni lomsebenzisi.Iqiniso lokuthi isisebenzisi sinomsebenzi wokuhlola ukuthi ukuncibilika bekulungile nokwenza kusebenze idivayisi emaphakathi.«Ngakho-ke, ukukhiqizwa kabusha kanye nezinga lekhwalithi eliqhubekayo alikwazi ukuqinisekiswa kusetshenziswa le nqubo.Ukusakazwa kokungeniswa kuyashesha kakhulu.Ingxubevange yensimbi iyashiswa kusukela ngaphakathi kuya ngaphandle.Imvelo yezobuchwepheshe yesistimu yokungeniswa yenza kube nzima ukuzinzisa izinga lokushisa le-alloy ngokuhamba kwesikhathi noma ukuvimba ukwanda kwezinga lokushisa.Ingcindezi ye-centrifugal i-unidirectional futhi imishini eminingi yokukhipha induction ayinayo isistimu ye-vacuum, ngakho-ke umoya otholakala kuyunithi ungabangela i-porous casting.

I-vacuum pressure die-casting

I-vacuum pressure die casting ibilokhu ibhekwa njengenqubo yokuphonsa yekhwalithi ephezulu, nokho ukuduma kwayo kwahlala kunqunyelwe kuze kube maphakathi nawo-90s ngenxa yokuthi amazinga okushisa afinyelelwe yilawa madivayisi ayengafaneleki ukuncibilika nokusakazwa kwama-alloys amazinyo amasha.Isizukulwane esisha samadivayisi athuthukiswa kamuva, ayekwazi ukuncibilikisa isisekelo sensimbi, i-semi-precious, i-Palladian kanye nama-alloys amazinyo ayigugu.

Imishini yokukhipha i-Hasung vacuum die-casting ifaka isilawuli sokushisa esincibilikayo esihle kakhulu, ekhiqiza ukuphonsa ku-vacuum futhi kwenze kube nokwenzeka ukwenza ingcindezi ye-multi-directional.Konke lokhu kuqinisekisa ukuguquguquka okukhulu kokusetshenziswa, ukukhiqizwa kabusha kanye nekhwalithi engaguquki futhi kunciphisa umthelela wesisebenzisi kumphumela.

Indlela yokufeza umphumela omuhle

Landela izimfuneko zokushisa zokusakaza

Ukugcina ukulawula izinga lokushisa lokusakaza kuyisidingo esibaluleke kakhulu sokugcina izici ze-metallurgic ze-alloy.Ukuhambisana nedatha yokusakaza kanye nokucaciswa kwemininingwane kubalulekile ukuze kugwenywe ukuncibilika kancane kwezinsimbi ezincibilika eziqukethwe ku-alloy.

Insimbi encibilikisiwe ekushiseni okufanelekile izoba nazo zonke izici ezinqunywe yinkampani ekhiqizayo, ngaphandle kwalokho kungase kube nezinguquko ezithile esakhiweni se-metallurgic yensimbi engase ibangele izinguquko ezindaweni zobuchwepheshe kanye nezinkinga phakathi nezigaba zokucubungula ezilandelayo.

Ukusakaza ngengcindezi ye-omnidirectional

Ama-alloys amazinyo akhiwe ngezinsimbi eziningana ezahlukene, ngayinye inobukhulu bayo obuthile.Ngokusebenzisa amasu omjovo we-centrifugal umphumela uyoba ukucindezela kwe-mono-directional lapho izinsimbi ezine-specific ephakeme ukuminyana kwethulwa kusilinda ngaphambi kwalezo ezinobukhulu obuphansi.Kusetshenziswa amasu okukhipha umfutho we-die-cast, insimbi yethulwa ngokwezibalo kusilinda bese isilinda sivezwa ku-omni-directional kanye nengcindezi engaguquki evumela ukubekwa kwensimbi okuphelele.

Ukukhipha i-vacuum

Ukuze kuzuzwe ukumelana okuphezulu kwemishini kanye nokunemba ukubunjwa kufanele kwenziwe endaweni engenawo umoya.Lokhu kuqinisekisa ukukhishwa kwe-alloy okungenayo i-porous ngokuphelele.

Izinzuzo ze-Hasung die-casting system

Ukuhambisana nezicaciso zezinga lokushisa elimisiwe

Lokhu kungenzeka ngenxa yesistimu ehlanganisa ukulawula nge-microprocessor, i-thermocouple kanye ne-control logic, eyenziwa ngesistimu ye-elekthronikhi eyinkimbinkimbi ene-infra-red pointer.

Izinzuzo: Ukunemba okuphezulu ekukhiqizeni ingxubevange ngokulondolozwa okulandelanayo kwezicaciso ze-metallurgic.

Ukucindezela kwe-Omnidirectional kunsimbi

Ukucindezela okuzenzakalelayo kukhiqiza umfaniswano ngisho nokucindezela kuwo wonke isilinda.Awukho umphumela we-centrifugal wezinsimbi ezihlanganisa i-alloy.

Izinzuzo: Ukubumbana kwe-alloy ephakeme, ukwendlaleka okungcono, ukonga okokusebenza kwengxubevange (asikho isidingo sempahla eyengeziwe ezosetshenziselwa amashaneli nezinto ezisansimbi ezeqile)

Ukuncibilika kwenziwa endaweni esemkhathini

Kodwa ukusakaza kwenziwa endaweni engenamoya ngoba uchungechunge lwe-TVC imishini yokuphonsa, ngaphambi kokugumbuqela, yenza inqubo yokukhiqiza yamahhala yomoya.

Izinzuzo: Ukunemba okuphezulu, ikhwalithi ephezulu nokonga isikhathi emisebenzini yokuqeda.

Ubukhulu bokuvumelana nezimo zokusebenza

Ukusebenziseka kwazo zonke izingxenye zaselabhorethri ngoba akukho ukungenelela komuntu.

Izinzuzo: Ukusebenziseka yizo zonke izingxenye zaselabhorethri.

Ukukhiqiza kabusha kwekhwalithi

Inqubo iyazenzakalela futhi ayinakho ukungenelela komuntu.

Izinzuzo: Umjikelezo ozenzakalelayo kanye nokungabikho kokungenelela komuntu kunikeza ukuphindaphindeka okuphelele kwemiphumela.

Ukuphatha ngempumelelo izindleko

Ukuphathwa kwenqubo sekukonke kubiza ngempumelelo okungu-100%: ukusetshenziswa kwamandla kagesi kuphansi futhi izinto ezisetshenziswayo azibizi.

Izinzuzo: ukusebenza kahle kwezindleko.

Izinto ezisetshenziswayo zomshini wokukhipha umfutho we-vacuum:

1. I-graphite crucible

2. I-Ceramic gasket

3. Ijazi le-Ceramic

4. Isivalo se-graphite

5. Thermocouple

6. Ikhoyili yokushisa

Umugqa ogcwele wokukhiqiza ubucwebe uhlanganisa:

1. Iphrinta ye-3D

2. Vulcanizer

3. Umjovo we-wax

4. Ihhavini eshile

5. Umshini wokukhipha umfutho we-vacuum

6. Ukuhlanza

7. Ukupholisha

Namuhla, izimboni zobucwebe zithanda ukuba nezinhlelo zokuphonsa ezizenzakalelayo eziphelele ezisindisa izindleko eziningi zabasebenzi futhi zikhulise ukusebenza kahle kokukhiqiza.Kwa-Hasung, sikunikeza izixazululo ezigcwele zokuphonsa ubucwebe emikhiqizweni yekhwalithi ephezulu kakhulu eqinisekisiwe evela e-China.

.png)