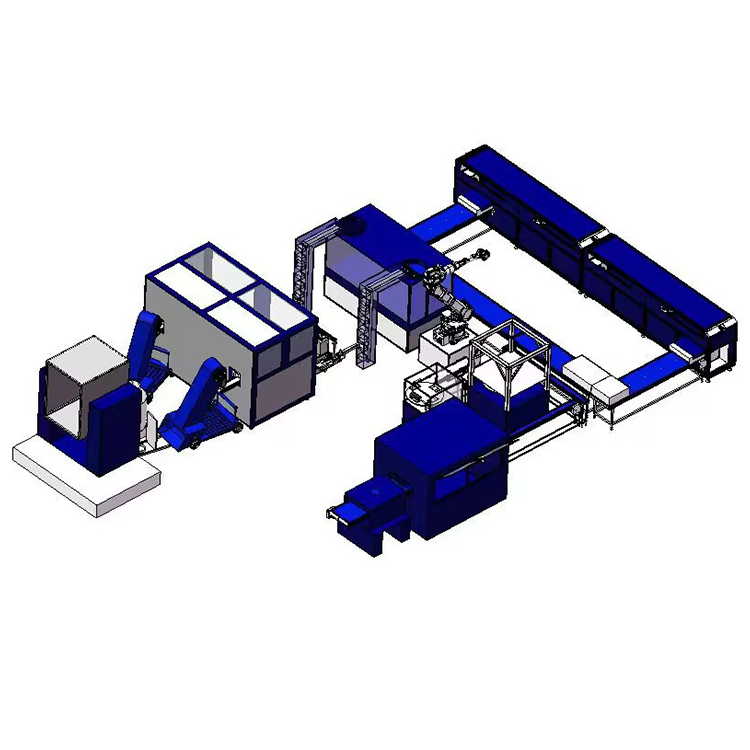

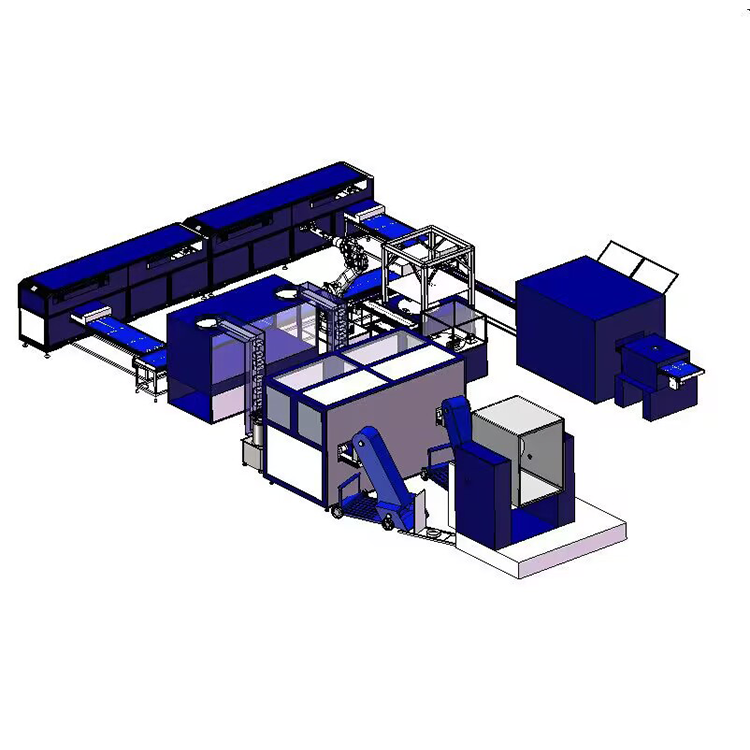

I-Tunnel Type Gold Ingot Vacuum Casting System

Isixazululo Esinengqondo

Eminyakeni edlule, imakethe yokutshala izinsimbi eziyigugu iye yaba yisidingo kakhulu: namuhla ingot kufanele ibe nezimpawu zobuhle ezifanayo zobucwebe.

Ngokusebenzisa imishini etholakala emakethe ngaphambi kokwethulwa kwe-HS-VF260, umuntu wayengakhiqiza imikhiqizo yekhwalithi ephusile, kodwa kwakunzima ku-opharetha ukuyiphatha. Eqinisweni, ukulinganiswa kwamapharamitha omsebenzi kanye nokugcinwa okuvamile bekulinganiselwe kuphela kubasebenzi abaqeqesheke kakhulu.

Ukwethulwa kwe-HS-VF260 kuguqule umkhakha: izinkampani emhlabeni wonke zahlinzekwa ngezithando zomhubhe eziklanyelwe, ezingakala ngokwezinhlobo zokukhiqiza (i-ingot isuka ku-1 ounce, kufika kuma-ounces angu-400 noma ama-ounces angu-1000), okwakufinyeleleka ukulungiswa kwayo.

Okuwukuphela kwesixazululo kwaba ukuklama isithando somlilo sokungeniswa esine-interface elula nesebenziseka kalula (isikrini sokuthinta se-HMI), esingahle sihlakazwe ngokuphelele ngesikrufu esisodwa.

Izinkinga Ezibucayi Nemibi Yohlelo Lwendabuko

Isithando somlilo sisendaweni evulekile futhi ilangabi lihlala livutha, yingakho izingozi zezingozi emsebenzini ziphezulu kakhulu.

Izingozi eziphakeme zokulahlekelwa kwensimbi.

Ukukhishwa kwentuthu okuphawulekayo, ukululama kwayo kubiza kakhulu enkampanini, kanye nokuthuthukiswa kwenkambu eqinile ye-electromagnetic.

Izinto eziningi ezisetshenziswayo, njengezinsimbi, zisetshenziswa futhi ziguge ngokushesha, okusho izindleko eziphezulu zokusebenza.

Izinga le-ingot eqediwe (ukukhanya, ukuhlanzeka, flatness) iphakathi-phezulu.

Isithando somlilo sidinga ukuba khona njalo kwabaqhubi.

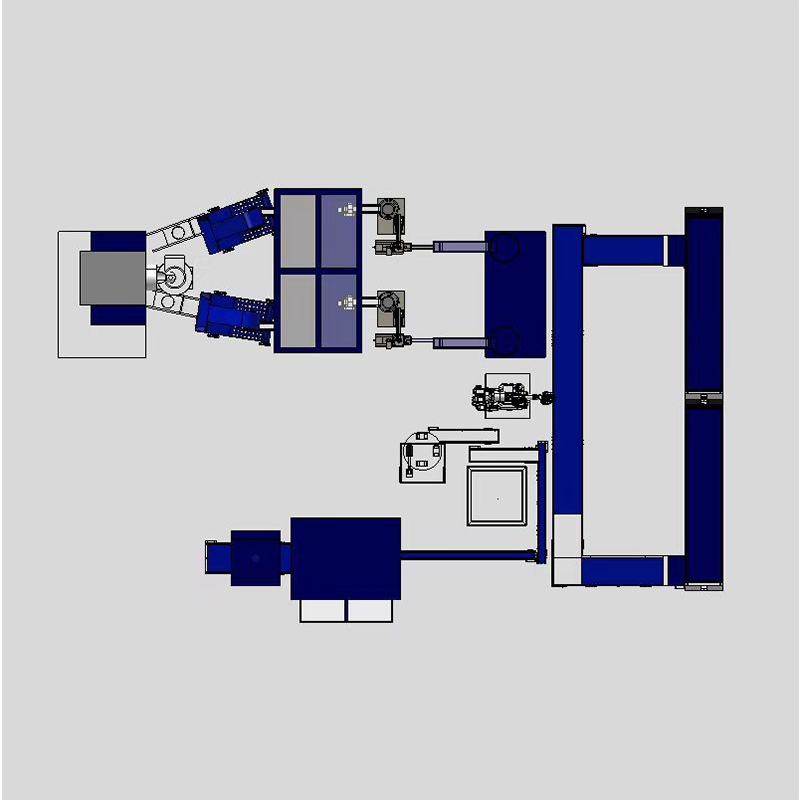

I-Tunnel Furnace Gold Vacuum Casting System

ukukhiqiza: amabhlogo ama-4/ihora, ibhulokhi ngalinye linesisindo esingu-15kg;

Ukushisa okuphezulu kokusebenza: 1350-1400 degrees Celsius;

Uhlobo lwegesi evikelayo: i-nitrogen; Ukusetshenziswa komoya: 5/H;

Ukushisa kwamanzi okungena kwesithando somlilo kanye nejeneretha: kufika ku-21 degrees Celsius;

Ukusetshenziswa kwamanzi okuphelele: 12-13 / H;

Ukucindezela kwamanzi okupholisa okudingekayo: 3 kuya ku-3,5 bar;

Ukugeleza komoya okudingekayo ukuze kungene umoya: 0.1 m/s;

Umfutho womoya odingekayo ovela esithandweni: 6 bar;

Uhlobo lombiko kanye nesihlukanisi: Graphite 400 oz;

Indawo yokufakwa kwesithando somlilo ingu-18.2M2, ubude buyi-26500mm, nobubanzi buyi-2800mm.

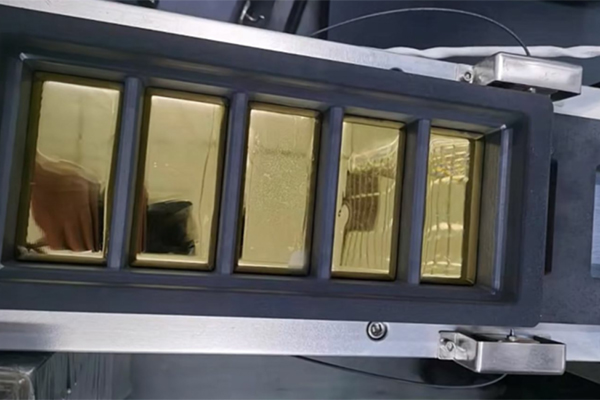

Indawo encibilikayo yomhubhe ilawulwa yizindawo/izindawo zokusebenza ezilandelayo:

Yakhelwe ngensimbi engagqwali. Isicelo: Ukupakisha izinhlayiya zegolide zibe amashidi e-graphite. Okuyinhloko

izingxenye: Ukususwa kwedivayisi ye-push-step kagesi.

Indawo yepharamitha yokufaka Sebenzisa:

Vimbela umoya ongaphandle ukuze ungangeni emhubheni Uhlelo lokupholisa: amanzi Izingxenye eziyinhloko: ukwahlukanisa okuhambayo okunokulawula umoya, umlomo womjovo Jova i-nitrogen.

Ukusetshenziswa kwendawo yokuncibilika:

esetshenziselwa ukuncibilikisa izinhlayiya zegolide Uhlelo lokupholisa: amanzi Izingxenye eziyinhloko: i-inductor efakwe usimende okhanyelayo, infrared

Inzwa yezinga lokushisa, isistimu yokulethwa kwe-nitrogen

Indawo yokupholisa:

i-partition enokulawula umoya, umlomo womjovo Faka i-nitrogen. futhi vacuum.

Indawo yokulayisha:

Yakhelwe ngensimbi engagqwali. Inhloso:

Khipha umkhiqizo oqediwe embikweni.

Imojula Yamandla, Imojula Ephelele: Ukunikezwa kwamandla: 380v, 50Hz; Izigaba ezi-3 Amandla kaGeneretha:

60kW; amanye angu-20KW. Amandla adingekayo: 80KW

Indawo yokulawula:

Indawo yokusebenza yazo zonke iziko

Isibonisi somkhiqizo

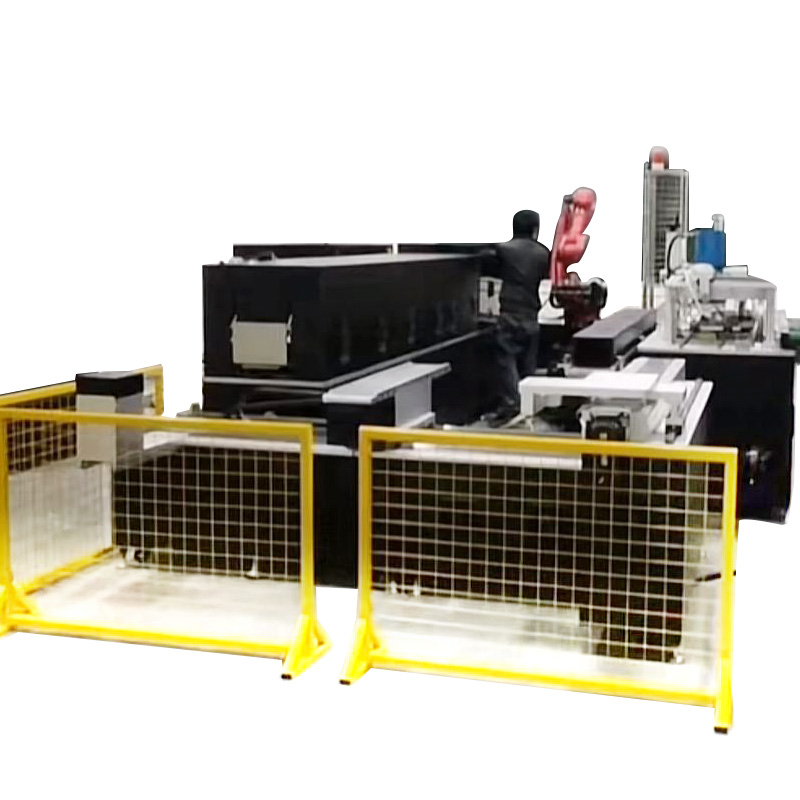

Uyini umugqa wokukhiqiza webha yegolide yomhubhe ogcwele ozenzakalelayo?

Umugqa wokukhiqiza webha yegolide yomhubhe ozenzakalelayo ngokugcwele: ukuguqula imboni yegolide

Imboni yegolide ibilokhu iwuphawu lwengcebo nokuchuma, futhi isidingo semigoqo yegolide siyaqhubeka nokukhula. Njengoba ubuchwepheshe buthuthuka, ukukhiqizwa kwezigxobo zegolide kuye kwashintsha kakhulu. Enye yentuthuko emisha kakhulu embonini umugqa wokukhiqiza wegolide we-tunnel ozenzakalelayo. Lobu buchwepheshe obusezingeni eliphezulu buye benza izinguquko endleleni amabha egolide akhiqizwa ngayo, kwathuthukisa ukusebenza kahle, ukunemba kanye nekhwalithi. Kulesi sihloko, sizohlola ukuthi uyini umugqa wokukhiqiza webha yegolide esebenza ngokuzenzakalelayo yomhubhe, ukuthi usebenza kanjani, nomthelela wawo embonini yegolide.

Uyini umugqa wokukhiqiza webha yegolide yomhubhe ozenzakalelayo?

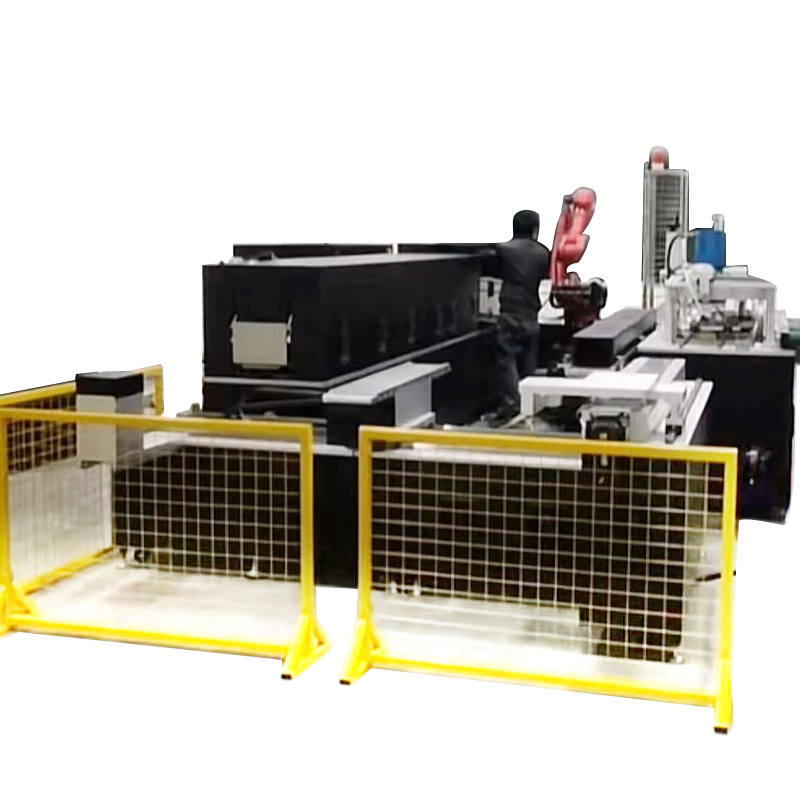

Ulayini wokukhiqiza ibha yegolide yomhubhe ozenzakalelayo ngokuphelele uwuhlelo oluthuthukisiwe oluklanyelwe ngokukhethekile ukukhiqizwa kwebha yegolide okuzenzakalelayo. Iqukethe uchungechunge lwemishini exhumene nezinto zokusebenza ezisebenza ndawonye ngaphandle komthungo ukuze ziguqule izinto zokusetshenziswa zibe izigxobo zegolide eziqediwe. Yonke le nqubo izenzekelayo ngokugcwele ngaphandle kokungenelela okwenziwa ngesandla, kunciphisa kakhulu ingozi yephutha lomuntu.

Ingxenye eyinhloko yalo mugqa isithando somlilo sikamhubhe, okuyisithando somlilo esiklanyelwe ukuncibilika futhi sicwengisise igolide. Isithando somlilo sifakwe isistimu yokulawula izinga lokushisa ethuthukisiwe nezinzwa zokuqinisekisa ukushisa okunembile nokungaguquki kwezinto zegolide. Ngaphezu kwalokho, ulayini wokukhiqiza uhlanganisa abathumeli abahlukahlukene, isikhunta, izinhlelo zokupholisa kanye nezindlela zokulawula ikhwalithi ukuze kuthuthukiswe yonke inqubo yokukhiqiza.

Umhubhe wesithando somlilo wegolide umugqa wokukhiqiza ibha yesiliva uhlanganisa

1. Metal granulator

2. Ukusefa ngesistimu yokudlidliza kanye nesistimu yokomisa

3. Dlulisa uhlelo lwe-vacuum

4. Uhlelo lokusebenzisa umthamo

5. Uhlelo lokulingisa ibha yegolide yomhubhe

6. Uhlelo lokuhlanza nokupholisha

7. Uhlelo lokumaka lwamachashazi

8. Ilogo yokugxiviza

9. Uhlelo lokupakisha

Isebenza kanjani?

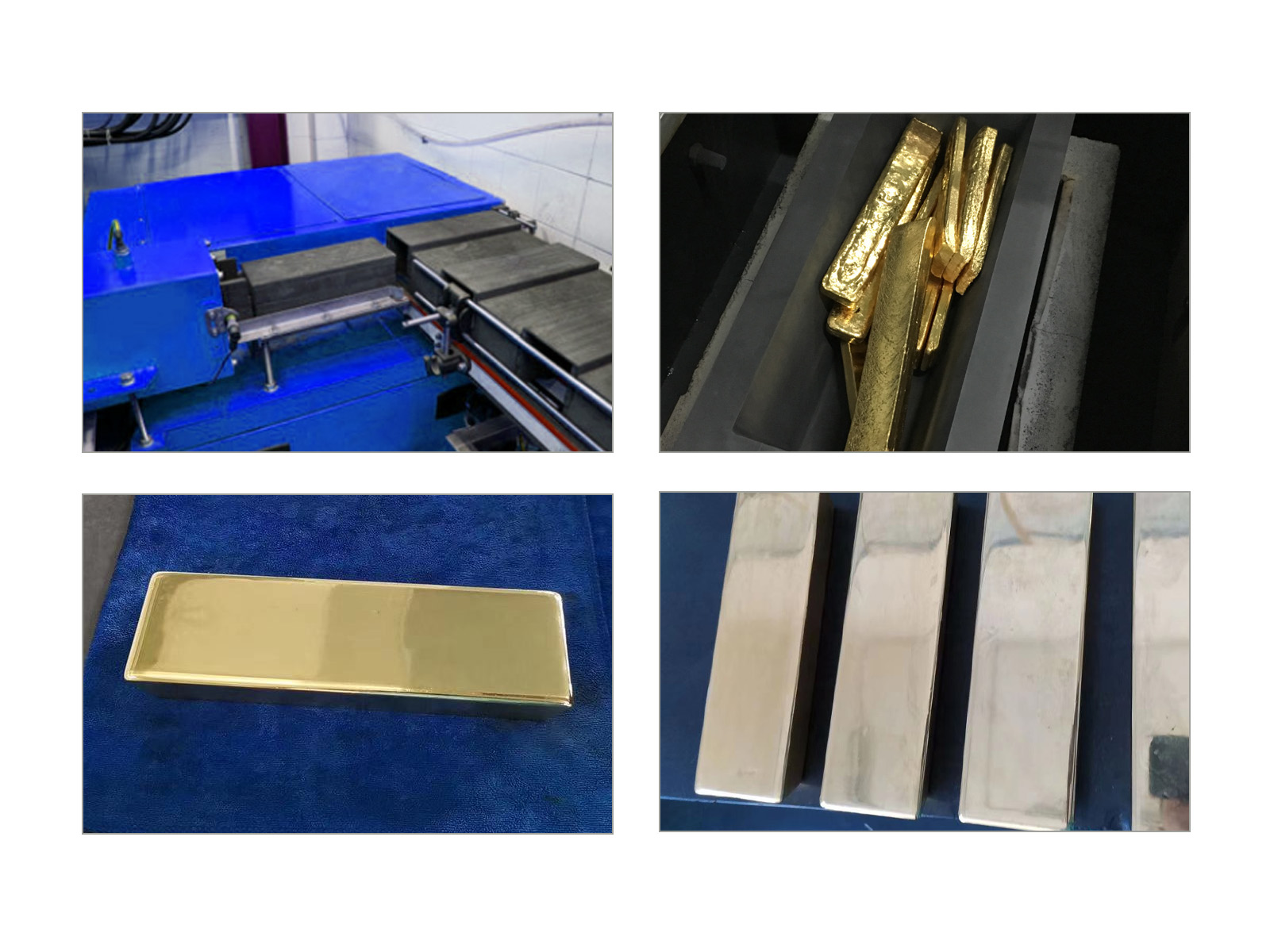

Ulayini wokukhiqiza webha yegolide esebenza ngokuzenzakalelayo yomhubhe usebenza ngochungechunge lwezigaba ezihlobene, ngayinye yakhelwe ukwenza umsebenzi othile ohlelweni lokukhiqiza ibha yegolide. Inqubo iqala ngokulayisha impahla yegolide eluhlaza esithandweni somlilo, lapho incibilikiswa khona futhi icwengisiswe ukuze kukhishwe ukungcola. Izinga lokushisa nobude besikhathi sokushisisa kulawulwa ngokucophelela ukuze kuzuzwe ubumsulwa obufunwayo kanye nokuvumelana kwegolide elincibilikisiwe.

Ngemva kokuba impahla yegolide icwengisisiwe, ithululelwa esikhunjeni futhi ibunjwe ngendlela efiswayo yebha yegolide. Isikhunta siklanywe kahle ukuthi sikhiqize imigoqo yegolide enobukhulu obuhlukahlukene nezisindo ukuhlangabezana nezidingo ezahlukene zemakethe. Ngemva kokuba igolide seliqinile, lithunyelwa ngesistimu yokupholisa ukuze lizinzise isakhiwo salo kanye nezinga lokushisa.

Ukulawulwa kwekhwalithi kuyisici esibalulekile somugqa wokukhiqiza, onezinhlelo zokuhlola ezithuthukisiwe ezididiyelwe ukuze kuqinisekiswe ukuthi imigoqo yegolide ihlangabezana namazinga aphezulu okuhlanzeka nekhwalithi. Noma yikuphi ukuchezuka noma ukonakala kuhlonzwa ngokushesha futhi kuxazululwe, kuqinisekiswe ukuthi kukhiqizwa izigxobo zegolide eziphelele kuphela.

Umthelela embonini yegolide

Ukwethulwa komugqa wokukhiqiza webha yegolide yomhubhe ozenzakalelayo ngokuphelele kube nomthelela omkhulu embonini yegolide. Lobu buchwepheshe obuthuthukisiwe buguqule inqubo yokukhiqiza, buletha izinzuzo ezibalulekile ezimbalwa ezibumba kabusha imboni.

Okokuqala futhi okubaluleke kakhulu, ukuzenzekelayo kwezinqubo zokukhiqiza kukhulisa kakhulu ukusebenza kahle nokukhiqiza. Ngokungenelela okuncane okwenziwa ngesandla, ulayini ungasebenza ngokuqhubekayo, ukhulise okukhiphayo futhi unciphise isikhathi sokukhiqiza. Lokhu kuvumela abacwengi begolide nabakhiqizi ukuthi bahlangabezane nesidingo esikhulayo samabha egolide ngempumelelo nangempumelelo.

Ukwengeza, ukunemba nokuvumelana okuzuzwa ngokuzenzakalelayo kuthuthukisa ikhwalithi yamabha egolide akhiqizwayo. Izinhlelo ezithuthukisiwe zokulawula izinga lokushisa kanye nezindlela zokuhlola ikhwalithi ziqinisekisa ukuthi amabha egolide ahlangabezana nezindinganiso eziphakeme zokuhlanzeka, efaka ukuzethemba kubathengi nakubatshalizimali.

Ngaphezu kwalokho, umugqa wokukhiqiza webha yegolide we-tunnel othomathikhi ngokugcwele uthuthukisa ukuphepha futhi unciphise umthelela wemvelo wokukhiqizwa kwebha yegolide. Ngokunciphisa ukubandakanyeka komuntu ohlelweni lokukhiqiza, ingozi yezingozi nokulimala iyancipha kakhulu. Ukwengeza, ukusetshenziswa ngendlela efanele kwamandla nezinsiza emigqeni yokukhiqiza ezenzakalelayo kunomthelela endleleni esimeme futhi enobungani nemvelo ekukhiqizeni ibha yegolide.

Ngaphezu kwalokho, ukwamukelwa kwalobu buchwepheshe obuthuthukile kwenza abakhiqizi begolide baqhudelane kakhulu emakethe yomhlaba. Ikhono lokukhiqiza izigxobo zegolide zekhwalithi ephezulu ngenani elisheshayo lizinikeza inzuzo yamasu, ezivumela ukuthi zihlangabezane nezidingo zabathengi bamazwe ngamazwe futhi zandise ukufinyelela kwazo emakethe.

Kafushane, ulayini wokukhiqiza webha yegolide esebenza ngokuzenzakalelayo yomhubhe umelela intuthuko enkulu embonini yegolide. Izinqubo zayo zokukhiqiza ezizenzakalelayo nezinembayo zithuthukisa ukusebenza kahle, ikhwalithi kanye nokuncintisana kokukhiqizwa kwebha yegolide. Njengoba isidingo segolide siqhubeka nokwenyuka, lobu buchwepheshe obusha buzodlala indima ebalulekile ekuhlangabezaneni nesidingo semakethe futhi kulolonge ikusasa lemboni yegolide.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur