I-WIRE BONDING

ISHIDI LEQINISO LESISEKELO ULWAZI

Kuyini i-Wire Bonding?

I-wire bonding yindlela okunamathiselwe ngayo ubude bocingo oluthambile lwensimbi oluyidayamitha encane endaweni ehambisanayo eyinsimbi ngaphandle kokusebenzisa i-solder, i-flux, futhi kwezinye izimo kusetshenziswa ukushisa okungaphezu kuka-150 degrees Celsius. Izinsimbi ezithambile zifaka igolide (Au), iCopper (Cu), isiliva (Ag), i-Aluminium (Al) nama-alloys afana nePalladium-Silver (PdAg) nezinye.

Ukuqonda Amaqhinga Nezinqubo Zokubopha Ngezintambo Zezicelo Zomhlangano We-Micro Electronics.

Amasu/Izinqubo Zokubopha Wedge: Iribhoni, Ibhola Le-Thermosonic & I-Ultrasonic Wedge Bond

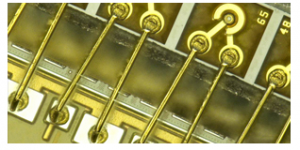

I-wire bonding yindlela yokwenza ukuxhumana phakathi kwesekethe edidiyelwe (IC) noma idivayisi ye-semiconductor efanayo kanye nephakheji yayo noma ifreyimu ehamba phambili ngesikhathi sokukhiqiza. Isetshenziswa futhi manje ukuhlinzeka ngoxhumano lukagesi kuma-asemblies ephakethe lebhethri ye-Lithium-ion.Isibopho socingo ngokuvamile sibhekwa njengosingambi kakhulu futhi sivumelana nezimo kobuchwepheshe obutholakalayo be-microelectronic interconnect, futhi sisetshenziswa kuningi lamaphakheji e-semiconductor akhiqizwa namuhla. kukhona izindlela ezimbalwa zokuhlanganisa izintambo, ezihlanganisa:I-Thermo-Compression Wire Bonding:

I-Thermo-compression wire bonding (ehlanganisa nendawo okungenzeka ukuthi ivele (imvamisa i-Au) ihlangene ngaphansi kwamandla okucindezela anamazinga okushisa aphezulu, ngokuvamile angaphezu kuka-300°C, ukuze kukhiqizwe i-weld), yaqale yathuthukiswa ngeminyaka yawo-1950 ukuze kuxhunywe ama-microelectronics, nokho lokhu ngokushesha kwathathelwa indawo yi-Ultrasonic & Thermosonic bonding ngeminyaka yama-60s njengobuchwepheshe obuvelele bokuxhumanisa. I-Thermo-compression bonding isasetshenziselwa izinhlelo zokusebenza ze-niche namuhla, kodwa ngokuvamile igwenywa abakhiqizi ngenxa yamazinga okushisa aphezulu (okuvame ukulimaza) adingekayo ukuze kwenziwe ibhondi eyimpumelelo.I-Ultrasonic Wedge Wire Bonding:

Ngawo-1960 i-Ultrasonic wedge wire bonding yaba yindlela ehamba phambili yokuxhumanisa. Ukusetshenziswa kokudlidliza kwefrikhwensi ephezulu (nge-transducer ezwakalayo) ethuluzini lokubopha elinamandla okubamba kanyekanye, kuvumele izintambo ze-Aluminium neGolide ukuthi zishiselwe ekamelweni lokushisa. Lokhu kudlidliza kwe-Ultrasonic kusiza ekususeni ukungcola (ama-oxides, ukungcola, njll.) ezindaweni ezibophezelayo ekuqaleni komjikelezo wokubopha, nasekukhuthazeni ukukhula kwe-intermetallic ukuze kuthuthukiswe nokuqinisa isibopho. Amafrikhwensi ajwayelekile okubopha ama-60 – 120 KHz.Isu le-ultrasonic wedge linobuchwepheshe benqubo obubili:Intambo enkulu (esindayo) yokubopha izintambo ezingu->100µm ubukhulu bezintambo ezinhle (ezincanyana) zezintambo ezingu-<75µm ububanziIzibonelo ze-Ultrasonic bonding evamile etholakala lapha ngocingo oluhle futhi lapha ngocingo olukhulu.Ultrasonic i-wedge wire bonding isebenzisa ithuluzi elithile le-bonding noma “wedge,” ngokuvamile eyakhiwa nge-Tungsten Carbide (ye-Aluminium wire) noma i-Titanium Carbide (yegolide legolide) kuye ngezidingo zenqubo namadiamitha ezintambo; i-ceramic tipped wedges zezinhlelo zokusebenza ezihlukile ayatholakala.I-Thermosonic Wire Bonding:

Lapho kudingeka khona ukushisisa okwengeziwe (ngokuvamile ocingweni lweGolide, olunezindawo zokuhlangana eziyibhondi ebangeni lika-100 – 250°C), le nqubo ibizwa ngokuthi i-Thermosonic wire bonding. Lokhu kunezinzuzo ezinhle kunohlelo lwendabuko lokuminyanisa kwe-thermo, njengoba kudingeka amazinga okushisa aphansi kakhulu esixhumi esibonakalayo (I-Au bonding emazingeni okushisa asekamelweni kukhulunywe ngayo kodwa ekusebenzeni akuthembeki ngaphandle kokushisa okwengeziwe).Thermosonic Ball Bonding:

Olunye uhlobo lwe-Thermosonic wire bonding i-Ball Bonding (bona umjikelezo webhondi yebhola lapha). Le ndlela yokwenza isebenzisa ithuluzi le-ceramic capillary bonding phezu kwemiklamo ye-wedge yendabuko ukuhlanganisa izimfanelo ezinhle kakhulu kukho kokubili ukucindezela kwe-thermo kanye ne-ultrasonic bonding ngaphandle kwezihibe. Ukudlidliza kwe-Thermosonic kuqinisekisa ukuthi izinga lokushisa lesikhombimsebenzisi lihlala liphansi, kuyilapho ukuxhumana kokuqala, ibhondi yebhola ecindezelwe ngokushisa ivumela ukuthi intambo kanye nebhondi yesibili ibekwe kunoma iyiphi indlela, ingahambelani nebhondi yokuqala, okuyisithiyo ekubopheni intambo ye-Ultrasonic. . Ekwakheni okuzenzakalelayo, ivolumu ephezulu, amabhondi ashesha kakhulu kune-Ultrasonic/Thermosonic (Wedge) amabhondi, okwenza ibhola le-Thermosonic libophe ubuchwepheshe obuvelele bokuxhuma kuma-microelectronics iminyaka engu-50+ edlule.I-Ribbon Bonding:

Ukuhlanganiswa kweribhoni, kusetshenziswa amateyipu ensimbi ayisicaba, bekulokhu kubusa ku-RF ne-Microwave electronics amashumi eminyaka (iribhoni ehlinzeka ngokuthuthuka okuphawulekayo ekulahlekeni kwesignali [umphumela wesikhumba] uma kuqhathaniswa nocingo oluyindilinga oluvamile). Amaribhoni Egolide amancane, ngokuvamile afika ku-75µm ububanzi no-25µm ubukhulu, ahlanganiswe ngenqubo ye-Thermosonic ngethuluzi elikhulu le-wedge elinobuso obuphansi. isidingo se-loop ephansi, ukuminyana okuphezulu kokuxhumana kunyukile.

Iyini i-golden bonding wire?

I-Gold wire bonding iyinqubo lapho intambo yegolide ixhunywa khona emaphoyintini amabili ekuhlanganiseni ukuze kwakhe ukuxhuma noma umzila oqhutshwa ngogesi. Ukushisa, ama-ultrasonics, namandla konke kusetshenziswa ukuze kwakhiwe amaphuzu okunamathiselwe ocingweni lwegolide.Inqubo yokudala indawo yokunamathisela iqala ngokwakhiwa kwebhola legolide esihlokweni sethuluzi lesibopho socingo, i-capillary. Leli bhola licindezelwa endaweni yomhlangano eshisayo ngenkathi kusetshenziswa kokubili inani lamandla aqondene nohlelo lokusebenza kanye nemvamisa engu-60kHz - 152kHz yokunyakaza kwe-ultrasonic ngethuluzi.Uma ibhondi yokuqala seyenziwe, ucingo luzosetshenziswa ngendlela elawulwa ngokuqinile. indlela yokwenza i-loop shape efanele yejometri yomhlangano. Isibopho sesibili, esivame ukubizwa ngokuthi i-stitch, sibe sesibunjwa kwenye indawo ngokucindezela phansi ngocingo nokusebenzisa i-clamp ukudabula ucingo kubhondi.

I-Gold wire bonding inikezela ngendlela yokuxhumana ngaphakathi kwamaphakheji asebenza ngogesi kakhulu, cishe ukuhleleka kobukhulu obukhulu kunamanye ama-solder. Ngaphezu kwalokho, izintambo zegolide zinokubekezelela okuphezulu kwe-oxidation uma kuqhathaniswa nezinye izinto zocingo futhi zithambile kuneningi, okubalulekile ezindaweni ezibucayi.

Inqubo nayo ingahluka ngokuya ngezidingo zomhlangano. Ngezinto ezibucayi, ibhola legolide lingabekwa endaweni yesibili yokubopha ukuze kwakheke kokubili isibopho esiqinile kanye nebhondi "ethambile" ukuvimbela ukulimala ebusweni bengxenye. Ngezikhala eziqinile, ibhola elilodwa lingasetshenziswa njengesiqalo samabhondi amabili, enze ibhondi emise okwe-“V”. Uma isibopho socingo sidinga ukuqina kakhulu, ibhola lingabekwa phezu kwesitishi ukuze lenze ibhondi yokuvikela, okwandisa ukuqina namandla entambo. Izinhlelo eziningi ezahlukene kanye nokwehluka ekuhlanganiseni izintambo cishe akunamkhawulo futhi kungafinyelelwa ngokusebenzisa isofthiwe ezenzakalelayo kumasistimu ebhondi yezintambo zikaPalomar.

Ukuthuthukiswa kwe-wire bonding:

I-wire bonding yatholwa eJalimane ngeminyaka yawo-1950 ngokubona kokuhlola okunenhlanhla futhi ngemva kwalokho kwathuthukiswa kwaba inqubo elawulwa kakhulu. Namuhla isetshenziswa kakhulu ekuxhumeni ngogesi ama-semiconductor chips ukupakisha imikhondo, amakhanda e-disk drive kuma-pre-amplifiers, nezinye izinhlelo zokusebenza eziningi ezivumela izinto zansuku zonke ukuthi zibe zincane, "zihlakaniphe", futhi zisebenze kahle kakhudlwana.

I-Bonding Wires Applications

Ukukhula kwe-miniaturization ku-electronics kube nomphumela

ekubopheni izintambo zibe yizingxenye ezibalulekile ze

imihlangano kagesi.

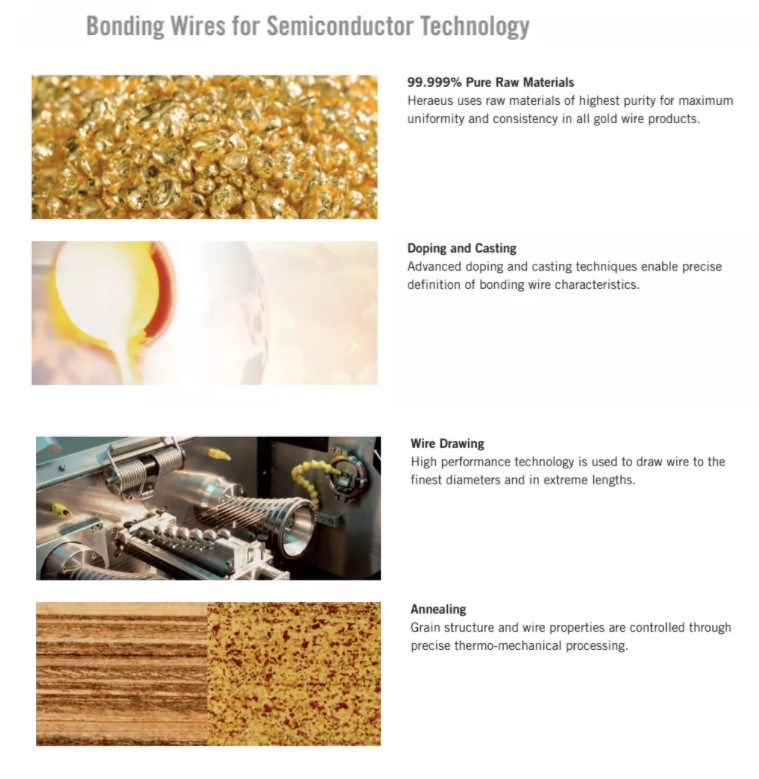

Ngale njongo izintambo zokubopha ezicolile nezine-ultrafine ze

kusetshenziswa igolide, i-aluminium, ithusi ne-palladium. Okuphakeme kakhulu

izimfuno zenziwa ngekhwalithi yazo, ikakhulukazi maqondana

ekufaneni kwezakhiwo zocingo.

Ngokuya ngokwakheka kwamakhemikhali nokuqondile

izakhiwo, izintambo zokubopha ziguqulelwe ekuhlanganiseni

inqubo ekhethiwe kanye nemishini yokubopha okuzenzakalelayo njenge

kanye nezinselele ezihlukahlukene kubuchwepheshe bokuhlanganisa.

I-Heraeus Electronics inikeza uhla lomkhiqizo olubanzi

ngezinhlelo zokusebenza ezahlukahlukene ze

Imboni yezimoto

Ezokuxhumana

Abakhiqizi be-semiconductor

Imboni yezimpahla zabathengi

Amaqembu omkhiqizo we-Heraeus Bonding Wire yilawa:

Izintambo zokubopha zokusetshenziswa kupulasitiki ogcwele

izingxenye ze-elekthronikhi

Izintambo zokuhlanganisa i-aluminium ne-aluminium ingxubevange ye

izinhlelo zokusebenza ezidinga izinga lokushisa eliphansi lokucubungula

Izintambo zokubopha ithusi njengendlela yobuchwepheshe kanye

enye indlela yokonga kunezintambo zegolide

Amaribhoni okubopha ensimbi ayigugu futhi angewona ayigugu

ukuxhumana kukagesi nezindawo ezinkulu zokuxhumana.

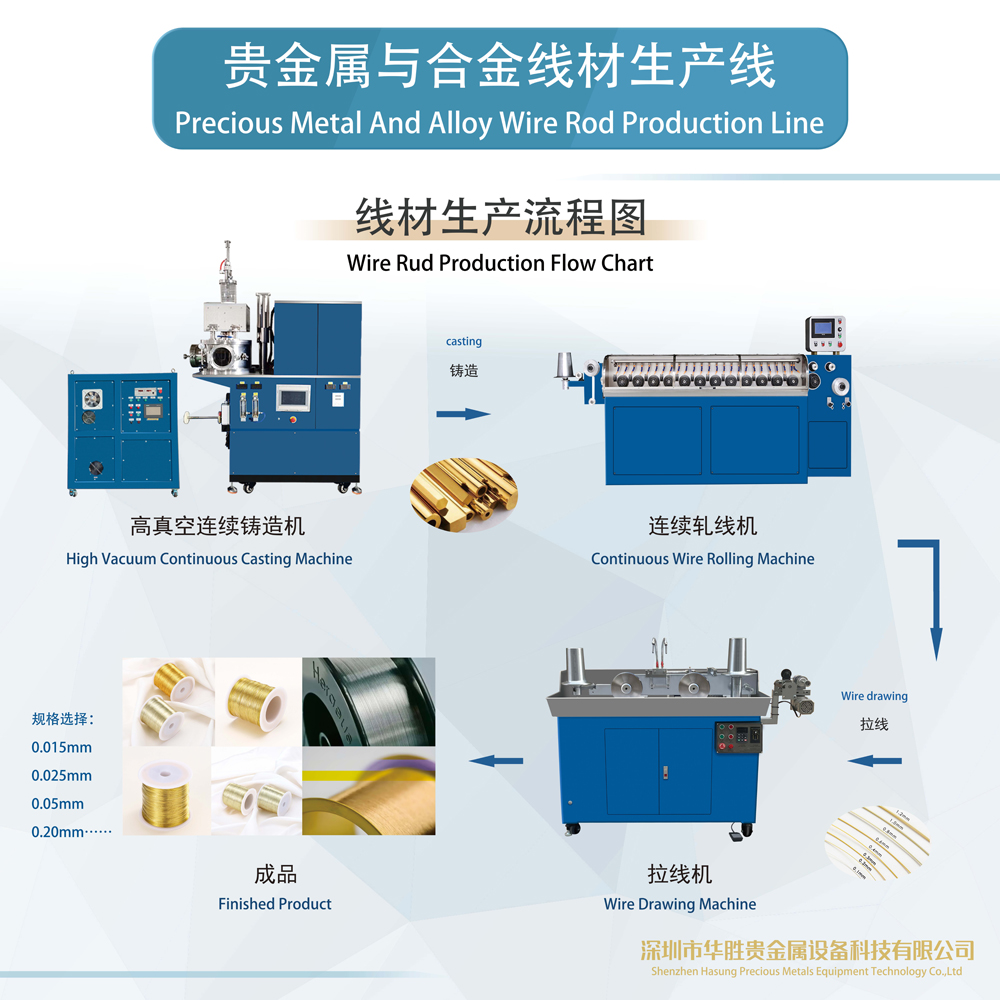

I-Bonding Wires Production Line

Isikhathi sokuthumela: Jul-22-2022