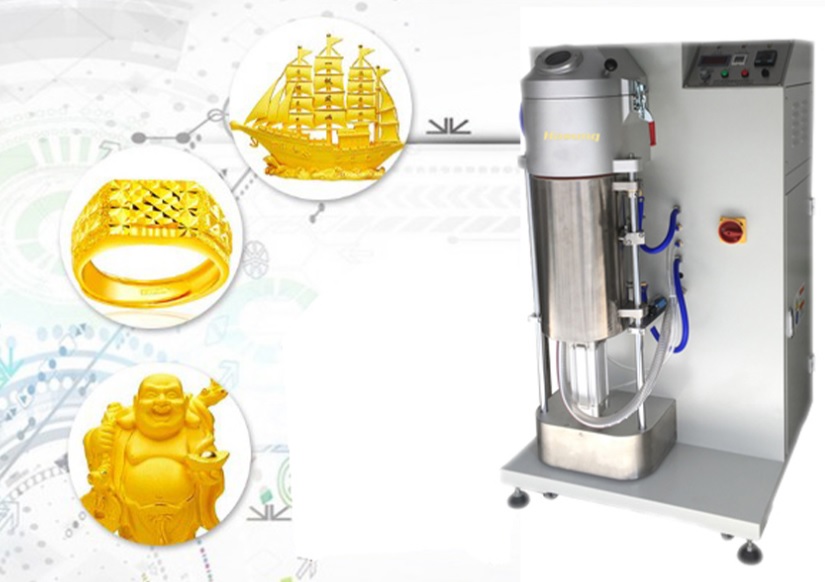

Ivacuum yegolide/yesilivaumshini wokuphonsa ubucwebeyakhelwe ubucwebe Castings.Lo mshini uklanyelwe ukuhlangabezana nezidingo ezinzima kakhulu ekukhiqizweni kwe-wax.Lo mshini usebenza nemiqondo emisha futhi unezinzuzo eziningana uma uqhathaniswa neminye imishini evamile.Izinzuzo zomshini we-vacuum wobucwebe ngaphezu kwemishini ejwayelekile zimi kanje:

Ngokuqhathaniswa isikhala esiningi sokubunjwa kwensimbi

Eyethuumshini wokwenza ubucwebeinendawo eyengeziwe uma iqhathaniswa neminye imishini yokuphonsa insimbi.Uma ukubunjwa kwenziwa ngokuba nenani elincane lensimbi ngesikhathi, kuzothatha isikhathi esikhulu ukwehlisa ukukhiqizwa.

Ukuncibilika kwe-vacuum nokusakazwa kokubili kwenziwa emshinini owodwa

Emishinini evamile ukuncibilika kwensimbi nokujikijelwa kwenziwa emishinini ehlukene eyehlisa inani lomkhiqizo njengoba kulahleka ubuningi obunye ekudluliseleni izinto ezincibilikisiwe zisuka komunye umshini ziye komunye.Kodwa emshinini wethu, zombili izinqubo zenziwa emshinini ofanayo oshiya imfuneko yokuhambisa insalela encibilikisiwe isuka komunye umshini iye komunye okuholela ekuthuthukiseni isivuno.

Ihlinzeka ngekhwalithi yensimbi yokusakaza

Nakuba ukulingwa kwensimbi akuqinisekisiwe kuyo yonke imishini.Eminye imishini ishiya insimbi inganyakaziswanga ngokuphelele okuholela emiphumeleni empofu yekhwalithi.Kodwa umshini wethu wokukhipha insimbi ye-vacuum uhlinzeka ngemikhiqizo yekhwalithi enhle, futhi uqinisekisa ikhwalithi ukuthi ibe ngcono kakhulu emikhiqizweni yethu.Inqubo yokuphonsa ingaphansi kwesimo sokucindezela ukugqugquzela ukugcwaliswa kwesikhunta kubukhulu.Ubucwebe obuqediwe bunesithando somlilo esibushelelezi, ukuminyana okuphezulu futhi akukho bubble emoyeni.

Ukunyakazisa okuqinile ukuqinisekisa umbala olinganayo

Emshinini wokuncibilika wensimbi nokuphonsa, ukunyakazisa kuyisici esibalulekile.Imishini evamile yokukhipha insimbi inezinga eliphansi lokunyakazisa elishiya umkhiqizo ngethoni engalingani.Ubucwebe obenziwa ngephimbo nombala ongalingani nakanjani bubukeka bungathandeki.Umshini wethu wokuphonsa ubucwebe osanda kuklanywa nothuthukisiwe uqinisekisa ukunyakazisa njalo.I-electromagnetic stirring isetshenziswa kulo mshini oqinisekisa ngisho nombala.

Isilinda sokusakaza esihlukile esihlukaniswe kudivayisi ye-vacuum

Nakuba ukuncibilika nokuphonsa kwenziwa emshinini ofanayo kodwa amasilinda azo zombili izinqubo agcinwa ehlukene ukuze kugcinwe umshini usebenza ngokushesha nangokuzimela.Inhloso yokugcina zombili izinqubo zihlukene ukuzigcina zizinhle ngokwekhwalithi.Uma kwenziwa kuhlangene khona-ke zombili izinqubo ziyathintana.

Umklamo ohlangene

Ngenxa yokwakheka kwawo okuhlangene, umshini wethu udinga indawo encane ukuze ufakwe.Idizayini encane futhi ehlangene yenza isetshenziswe kuzo zonke izinhlobo zezindawo kungaba izimboni ezinkulu noma ezincane.Futhi umsebenzi wemishini emibili ehlukene wenziwa emshinini owodwa onamasilinda amabili ahlukene, ngakho kunenzuzo eyengeziwe yokusebenzisa isikhala esincane.

Isistimu ye-alamu

Ama-alamu ahlukahlukene ahlanganiswe emshinini ukuze amise inqubo yokuncibilika nokuphonsa emshinini ngokushesha ukuze ugweme noma yikuphi ukulahlekelwa.Le alamu igcina isistimu yakho ikude nanoma yiluphi uhlobo lokulimala emshinini okungenzeka ngenxa yewashi lenqubo eyodwa.Kwengeza ekusebenzeni kahle kohlelo.

Inqubo yokusakaza esheshayo

Njengoba lo mshini usekela inani elengeziwe lensimbi (igolide) ngesikhathi, uqinisa izinga lokukhiqiza.Futhi amasilinda amabili ahlukene okwenza ukulingisa nokuncibilika ahlukane enza ukusebenza kube ngcono kuholele ekuvuneni okungcono.

Uhlelo lokulawula izinga lokushisa le-PID

Uhlelo lokulawula izinga lokushisa lugcina umshini wokuphonsa ubucwebe be-vacuum ekukhuphuleni izinga lokushisa kuze kube sezingeni elingase libe yingozi emshinini noma elingafanele inqubo yokuncibilika nokuphonsa insimbi.Izinga lokushisa eliphakeme aliyona nje ingozi emshinini we-vacuum kuphela kodwa liphinde libilise insimbi obekumele incibilike bese insimbi yonakala.Umshini wethu we-vacuum unamandla okubekezelela izinga lokushisa elingu-±1°C nomthamo wokushisa ophezulu ongu-1600°C.

Izinketho ezizenzakalelayo ne-semi-auto ziyatholakala

Isikhathi esiningi abasebenzi bayafuneka ukuze baqhube imishini, futhi badinga ukuba seduze nomshini ukugwema ukulimala emshinini, noma ukunqoba izimo uma umshini ungasebenzi kahle.Lokhu kudinga inani elikhulu labasebenzi ukuthi baphathe ukusebenza kwenani elikhulu lemishini embonini.Umshini wethu omusha wokukhipha ubucwebe be-vacuum wenzelwe ukusebenza ngaphansi kwazo zonke izimo.Ihlinzekwa ngezinketho ezizenzakalelayo ne-semi-automatic ukuphatha umshini ngaphandle kwabasebenzi abengeziwe.Izilungiselelo ze-semi-automatic zingalungiswa njengoba kudingeka ukuze wenze umshini usebenze njengoba udinga.Lokhu kunciphisa isidingo sabasebenzi abengeziwe ukuze banakekele imishini.Izinzuzo ezinkulu zomshini wethu wokuphonsa ubucwebe be-vacuum ziningi uma ziqhathaniswa nemishini evamile yokuncibilika kwensimbi nokuphonsa.Kwenyusa izinga lokukhiqiza kanye nesivuno sesisonke futhi kunciphisa izindleko zabasebenzi, okwenza kube nenzuzo enkulu ebhizinisini lakho.Futhi inikeza imikhiqizo yekhwalithi engcono kakhulu engase ikhulise amaklayenti akho emhlabeni jikelele.Lo mshini ozuzisa kakhulu ufakazelwe ukuthi ufanelekile ukuba nawo.

Ukuze uthole Ulwazi Olwengeziwe Sicela Usithumele I-imeyili: -info@hasungmachinery.com

Isikhathi sokuthumela: Jun-30-2022