Umshini Wokuncibilikisa We-Tilting Induction Wegolide I-Silver Copper 2kg 3kg 4kg 5kg 6kg

Izici

I-Hasung Dual Use isithando somlilo esincibilikisa igolide neplatinamu ingancibilikisa iplatinum, isiliva, igolide, i-palladium nama-alloys athile ngempumelelo nangokuzikhandla.

Usayizi ohlangene wesithando somlilo seplatinamu wenza kube lula ukuhambahamba.

Isithando somlilo se-Hasung esincibilikisa igolide ne-platinum esisetshenziselwa izinto eziningi sifanelekile ekuncibilikeni okuncane ngoba sincibilika cishe ngo-1g kuya ku-2kg wezinsimbi ngesikhathi esisodwa, ngakho-ke, amabhizinisi amancane adinga ukuncibilika akudingeki akhathazeke ngokuthola isithando somlilo esihlangabezana nezidingo zabo zokuncibilika kuphela.

Ukusetshenziswa kwamandla kwesithando somlilo esincibilikisa iplatinamu kungu-15kw, lokhu kusho ukuthi amandla ayalondolozwa uma kuncibilika ngesithando somlilo seplatinamu futhi akudingekile ukuba ukhathazeke ngokusetshenziswa kwemali eyengeziwe emandleni engeziwe.

Isithando somlilo se-Hasung esincibilikisa igolide ne-platinum esinemisebenzi eminingi singahlangabezana nezidingo zokuncibilika esitolo sobucwebe, izimba izinsimbi zokungcebeleka, izikhungo zocwaningo kanye nokugaywa kabusha kwezinsimbi ezindala.

Isithando somlilo esincibilikisa igolide se-Hasung senjongo eminingi ne-platinum siphephile ngokwemvelo ukuze sisetshenziswe ngendlela yokuthi isithando somlilo singakhiqizi amagesi ayingozi noma senze umsindo ophazamisayo. Kuphephile futhi ukuthi abasebenzi basebenze njengoba ukuchitheka kwensimbi encibilikisiwe kungenzeki.

Isikhathi sokuncibilika siyashesha kakhulu, isithando somlilo seplatinamu sincibilika ku-2100 ℃ phakathi nemizuzu emi-2, ngaleyo ndlela, kwandise umsebenzi wakho nokusebenza kahle kokukhiqiza.

Zonke izinsimbi ezincibilikisiwe ngesithando sethu sokuncibilika seplatinamu ngokuvamile zinokufana okufanayo ukuze uma insimbi enjalo iphonswa, ibe nesiphetho sekhwalithi ephezulu.

Umsebenzi onyakazayo we-electromagnetic induction okhona ngaphakathi kwesithando somlilo seplatinamu wenza inqubo yokuncibilika isebenze kahle ngokudlulisa ukushisa ngokulinganayo futhi zonke izingxenye zensimbi zincibilike ngokulinganayo. Lokhu kusho futhi ukuthi konke ukushisa okudingekayo ekuncibilikeni kusetshenziswa ngokuphelele ngaphakathi kwesithando somlilo, ngakho-ke, akukho ukwanda kwezinga lokushisa kwendawo yokuncibilika.

Isistimu yokupholisa amanzi eyakhelwe ngaphakathi ekhona ngaphakathi kwesithando somlilo yenza izinga lokushisa lokuncibilika kwesithando somlilo lilawulwe, ngaleyo ndlela livimbele ukushisa ngokweqile.

Ubuchwepheshe bokushisa lokungeniswa obukhona ngaphakathi kwesithando somlilo seplatinamu benza ukungeniswa kwe-electromagnetic kwenzeke, okusho ukuthi wonke amandla adingekayo ekuncibilikeni asetshenziswa ngokuphelele ngaphakathi kwesithando somlilo esincibilikayo.

Isithando somlilo seplatinamu kulula kakhulu ukusebenza. Iphaneli yokulawula yenza kube lula kuwe ukulawula nokuqapha inqubo yokuncibilika.

Isithando somlilo esincibilikisa igolide se-Hasung sezinhloso eziningi neplatinamu siphephile ngokwemvelo njengoba akukho ukushisa okubangwayo ngesikhathi sokusetshenziswa, akukho gesi ekhishwayo futhi akukho msindo oba khona lapho kuncibilika ngesithando somlilo seplatinamu.

Umthamo wokuncibilika wanoma iyiphi indawo encibilikayo efinyelela ku-2100 ℃ ngokuvamile uzodla amandla engeziwe, kodwa okokusebenza kwethu okuncibilikisa igolide okudayiswayo kudinga kuphela u-15kw ukuze kuqale ukuncibilika ukuze kungabizi kakhulu.

Konke ukuncibilika kwe-8kg kwenziwa kahle emizuzwini emi-3, isici esingenakunqotshwa semishini yokuncibilikisa igolide ethengiswayo. Isivinini sokuncibilika sikusiza ukuthi uhlangabezane nazo zonke izidingo zokuncibilika ngokushesha nakalula.

Igolide, isiliva, ithusi, ithusi, iplatinamu nezinye izinhlaka zingancibilika ngempahla yethu yokuncibilikisa igolide. Lokhu kukwenza ukwazi ukonga imali kwezinye izinto ezincibilikisayo.

Isistimu yepompo yamanzi ekhona ezintweni zethu zokuncibilikisa igolide iyenza igcine izinga lokushisa elivamile lapho ukuncibilika kuqhubeka. Ngaleyo ndlela, wonga imali ezintweni zokupholisa.

Imishini yethu yokuncibilikisa igolide ifanele ukuncibilikisa izinsimbi zokucwaninga nokufundisa, izisekelo, izinsimbi ezigaywa kabusha ezitolo zobucwebe, njll.

Mayelana nomthelela wayo endaweni ezungezile, umsindo wezinto ezincibilikisa igolide nesiliva ngesikhathi sokuncibilika uphansi uma kuqhathaniswa futhi akukho kukhishwa kwegesi, intuthu noma uthuli nakho kuphansi.

Uma kuqhathaniswa neziqhumiso zokumelana nezimbawula ze-propane, imishini yokuncibilikisa igolide ye-Hasung iqinisekisa ukuthi akukho ukulahlekelwa kwezinsimbi ngesikhathi sokuncibilika, okwenza imishini yethu yokuncibilika isebenze kahle kakhulu kunawo womabili ama-oveni angamelana nezimbawula ze-propane.

Imishini yethu yokuncibilikisa igolide nesiliva ingasebenza ngokuqhubekayo isikhathi esingamahora angama-24.

Umsebenzisi wezinto zokuncibilikisa igolide unokulawula okuphelele kwemingcele yokuncibilika. Uma kwenzeka iphutha, isistimu yokuxwayisa ye-omni-directional isiza ukuphakamisa ama-alamu lapho amaphuzu angaba yingozi afinyelelwa ngesikhathi sokuncibilika, ngaleyo ndlela kuqinisekiswe ukuphepha komsebenzisi.

Ukugcinwa kwezinto ezincibilikisa igolide nesiliva kulula njengoba izinsimbi zihlukaniseka futhi zingahlanzwa ngemva kwenqubo ngayinye yokuncibilika.

Imingcele Yezobuchwepheshe

| Imodeli No. | I-HS-TF2 | I-HS-TF3 | I-HS-TF4 | I-HS-TF5 | I-HS-TF6 | I-HS-TF8 | I-HS-TF10 |

| Amandla | 8KW/15KW | 15KW | 15KW / 20KW | ||||

| Amandla kagesi | 380V, 50Hz, 3 izigaba | ||||||

| I-Max Temp | 1600°C | ||||||

| Isikhathi Sokuncibilika | 2-3 amaminithi. | 3-5 imiz. | 3-6 imiz. | 4-8 imiz. | 5-8 imiz. | 5-8 imiz. | 6-8 imiz. |

| Ukunemba Kwesikhashana | ±1°C (usebenzisa isilawuli se-PID ngokuzikhethela) | ||||||

| Ukulawula izinga lokushisa kwe-PID | Ongakukhetha | ||||||

| Amandla (Igolide) | 2KG | 3KG | 4KG | 5KG | 6KG | 8KG | 10KG |

| Isicelo | Igolide, i-K igolide, isiliva, ithusi namanye ama-alloys | ||||||

| Uhlobo lokupholisa | I-water chiller (ithengiswa ngokwehlukana) noma Amanzi agijimayo (ipompo yamanzi) | ||||||

| Indlela yokushisa | Germany IGBT Induction Ukushisa ubuchwepheshe | ||||||

| Ubukhulu | 90x48x100cm | ||||||

| Isisindo Esiphelele (approx.) | 90kg | 90kg | 100kg | 110kg | 120kg | 130kg | 160kg |

| Isisindo Sokuthumela (approx.) | 160kg | 175kg | 180kg | 190kg | 200kg | 220kg | 220kg |

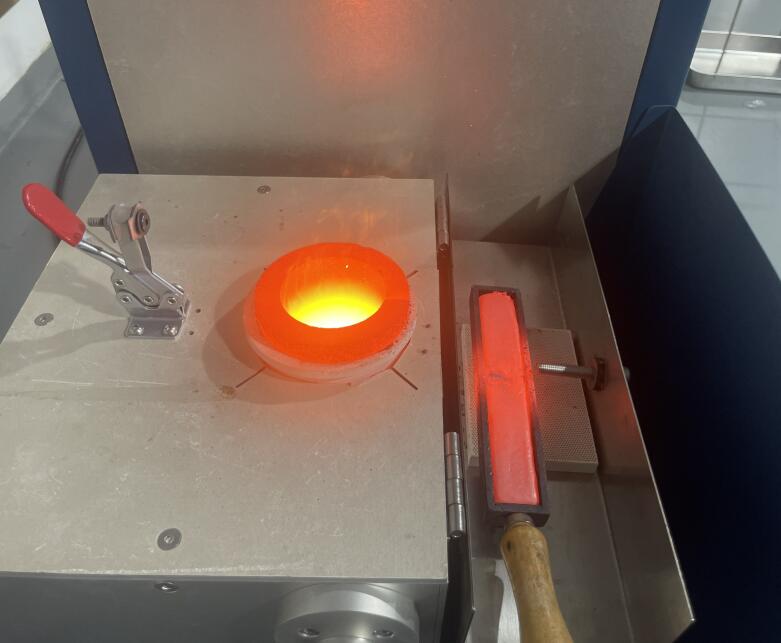

Isibonisi somkhiqizo

-18.png)

Isihloko: Izinzuzo ze-Hasung manual tilt casting induction melting furnace

Emhlabeni wokusebenza kokusakazwa kwensimbi, iziko lokuncibilikisa lokuncibilikisa le-tilt-cast seliphenduke ithuluzi elibalulekile ngenxa yokusebenza kahle kwazo, ukuphepha kanye nokusungula izinto ezintsha. Lo mklamo othuthukisiwe wesithando somlilo unikeza izinzuzo eziningi kubaqhubi nabakhiqizi, okwenza kube ukukhetha okudumile ngaphakathi kwemboni. Kule bhulogi, sizohlola izinzuzo eziningi zesithando somlilo esincibilikisa i-tilt-cast induction okwenziwa ngesandla kanye nokuthi izici zayo ezintsha, njengethreyi elizungezayo lokubunjwa kwe-graphite nomsebenzi wekhwalithi ephezulu, zifaka isandla ekusebenzeni kwaso okuphezulu.

Iziko lokuncibilikisa lokuncibilika lokunyakaziswa kwe-tilt manual linikeza uhla lwezinzuzo ezibenza babe yimpahla ebalulekile emisebenzini yokusakazwa kwensimbi. Enye yezinzuzo eziyinhloko zalesi sithando somlilo umsebenzi wayo wokutsheka ngesandla, ovumela ukulawula okunembile kwenqubo yokuthulula. Lokhu akugcini nje ngokuqinisekisa ukuvumelana futhi ngisho nokuthela, futhi kunciphisa ubungozi bokuchaphazeka noma ukuchitheka, kuhlinzeka ngendawo yokusebenza ephephile kubaqhubi. Ikhono lokutshekisa isithando somlilo mathupha linikeza opharetha ukuguquguquka okukhulu nokulawula, okubavumela ukuthi bathulule insimbi encibilikisiwe kalula nangokunemba.

Ngaphezu kwalokho, ukusungulwa kwethreyi ejikelezayo yesikhunta se-graphite kwenza i-Hasung manual tilting ithela isithando somlilo esincibilikisayo sihluke kumishini yokuncibilika yendabuko. Lesi sici esisha senza isithando somlilo sikwazi ukwamukela isikhunta esiningi, ngaleyo ndlela sikhulise ukusebenza kahle kanye nokukhiqiza kwenqubo yokuphonsa. Amaphalethi ajikelezayo avumela izinguquko zesikhunta ezingenamthungo, ukunciphisa isikhathi sokuphumula nokwenza lula ukukhiqizwa. Ukwengeza, ubuciko bezinga eliphezulu besithando somlilo buqinisekisa ukuqina nokuthembeka, okulenza libe utshalomali lwesikhathi eside lwezisekelo nezindawo zokuphonswa kwensimbi.

Iziko lokuncibilikisa lokuncibilika lokunyakaziswa kwe-tilt manual linikeza uhla lwezinzuzo ezibenza babe yimpahla ebalulekile emisebenzini yokusakazwa kwensimbi. Enye yezinzuzo eziyinhloko zalesi sithando somlilo umsebenzi wayo wokutsheka ngesandla, ovumela ukulawula okunembile kwenqubo yokuthulula. Lokhu akugcini nje ngokuqinisekisa ukuvumelana futhi ngisho nokuthela, futhi kunciphisa ubungozi bokuchaphazeka noma ukuchitheka, kuhlinzeka ngendawo yokusebenza ephephile kubaqhubi. Ikhono lokutshekisa isithando somlilo mathupha linikeza opharetha ukuguquguquka okukhulu nokulawula, okubavumela ukuthi bathulule insimbi encibilikisiwe kalula nangokunemba.

Ngaphezu kwalokho, ukusungulwa okusha kwethreyi ejikelezayo yesikhunta se-graphite kwenza i-manuwali tilting ithela isithando somlilo sokuncibilika sihluke kumishini yokuncibilika yendabuko. Lesi sici esisha senza isithando somlilo sikwazi ukwamukela isikhunta esiningi, ngaleyo ndlela sikhulise ukusebenza kahle kanye nokukhiqiza kwenqubo yokuphonsa. Amaphalethi ajikelezayo avumela izinguquko zesikhunta ezingenamthungo, ukunciphisa isikhathi sokuphumula nokwenza lula ukukhiqizwa. Ukwengeza, ubuciko bezinga eliphezulu besithando somlilo buqinisekisa ukuqina nokuthembeka, okulenza libe utshalomali lwesikhathi eside lwezisekelo nezindawo zokuphonswa kwensimbi.

Ngokungeziwe ekuphepheni nasekusunguleni izinto ezintsha, iziko lokuncibilikisa le-tilt-and-cast induction ngesandla linikeza izinzuzo ezibalulekile mayelana nokusebenza kahle kwamandla kanye nokusebenza kahle kwezindleko. Ubuchwepheshe bokushisa okufakwayo obusetshenziswa kulezi ziko buncibilikisa insimbi ngokushesha nangokunembile, kunciphisa ukusetshenziswa kwamandla kanye nezindleko zokusebenza. Lokhu kwenza isithando somlilo singagcini nje ngokuhambisana nemvelo, kodwa futhi sisebenze ngokwezomnotho kuma-Foundries kanye nezindawo zokuphonsa insimbi. Amandla okuthola ukusebenza kahle kokuncibilika okuphezulu kuyilapho unciphisa ukusetshenziswa kwamandla kuyinzuzo eyinhloko yeziko lokuncibilikisa le-tilt-cast induction.

Ukwengeza, iziko lokuncibilikisa lokuncibilika kwe-induction lokutsheka ngesandla liklanyelwe ukuhlangabezana nezidingo ezihlukahlukene zokusebenza kokusakazwa kwensimbi, okuhlinzeka ngezinto ezihlukahlukene kanye nokuvumelana nezimo ezinhlotsheni zezinhlelo zokusebenza. Kungakhathaliseki ukuthi okokukhiqiza okuncane noma imisebenzi yokuphonsa ngezinga elikhulu, isithando somlilo singashintshwa sibe namandla ahlukene okuncibilika kanye nezinhlobo zensimbi, okusenze sibe yisixazululo esisebenza ngezindlela eziningi nesisebenzayo kubakhiqizi. Ukuguquguquka kwesithando somlilo kuvumela ukuhlanganiswa okungenamthungo ezinqubweni ezikhona zokukhiqiza, okwandisa ukusebenza kahle okuphelele nokukhiqiza.

Kafushane, iziko lokuncibilikisa lokuncibilika kwe-tilt-cast manual linikeza izinzuzo eziningi ezibenza babe yithuluzi elibalulekile lokuphonswa kwensimbi nokusebenza kwe-Foundry. Izici zayo zokuphepha, idizayini emisha, ubuciko bezinga eliphezulu, ukusebenza kahle kwamandla kanye nokuguquguquka kwenza kube utshalomali olubalulekile kubakhiqizi abafuna ukuthuthukisa izinqubo zabo zokusakaza. Ngokulawula kwayo okunembile kwenqubo yokuthela, ithreyi ejikelezayo emisha yokubunjwa kwe-graphite nokusebenza okungabizi kakhulu, lesi sithando somlilo siwushintsho lomdlalo embonini yokuphonsa izinsimbi. Njengoba isidingo sekhwalithi ephezulu, imishini encibilikayo esebenzayo iqhubeka nokukhula, iziko lokuncibilikisa le-tilt-cast induction liba yisixazululo esinokwethenjelwa nesithuthukisiwe kubakhiqizi abafuna ukukhulisa amandla abo okuphonsa.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur