Umbukiso Wevidiyo

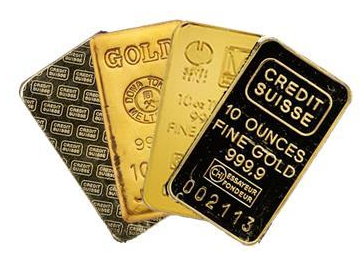

I-Hasung njengomhlinzeki wesisombululo sensimbi eyigugu eyigugu yokwenziwa kwensimbi, yakhe izinhlamvu zemali eziningana enza imigqa emhlabeni jikelele. Isisindo sohlamvu lwemali sisukela ku-0.6g kuya ku-1kg wegolide elinobunjwa obuyindilinga, obuyisikwele, nonxantathu. Ezinye izinsimbi nazo ziyatholakala njengesiliva nethusi.

Ungakwazi ukubhanga nge-Hasung ukukunikeza isixazululo sokuma okukodwa kweumugqa wokwenza uhlamvu lwemali. Iphakheji yokukhiqiza ihlanganisa ukuqondisa okusendaweni, imishini yokwenza uhlamvu lwemali, kanye nonjiniyela ukukusiza ukukala ngenqubo. Onjiniyela bethu babambe iqhaza ocwaningweni lwenqubo yokwenza uhlamvu lwegolide futhi basebenze njengabaxhumanisi bezobuchwepheshe beminti emikhulu eyaziwayo.

U-Hasung ugxile ekuxazululeni izinkinga zokwenziwa kohlamvu lwemali ngenkathi enikeza imiyalelo yesinyathelo nesinyathelo ngezinsimbi eziyigugu. Iminyaka engu-20+ besihamba phambili emshinini wokwenza uhlamvu lwegolide nesiliva, sinesevisi yobunjiniyela obuchwepheshile, ukuqeqeshwa esizeni, nokusekelwa kwezobuchwepheshe.

Sicela uchofozeumshini wokuphonsa oqhubekayo kanye nemishini yokugoqaukuze ubuke imininingwane.

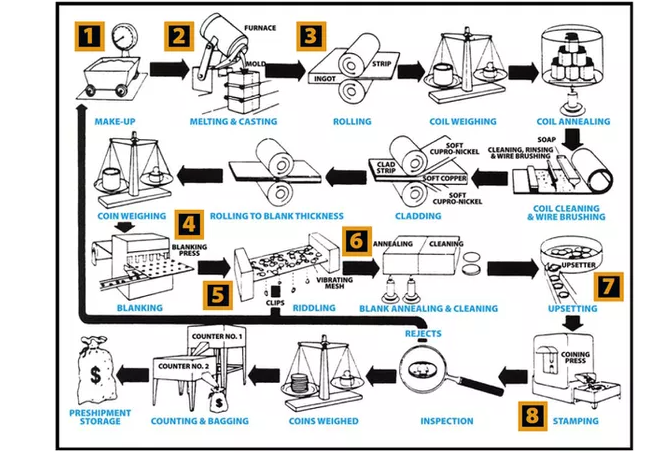

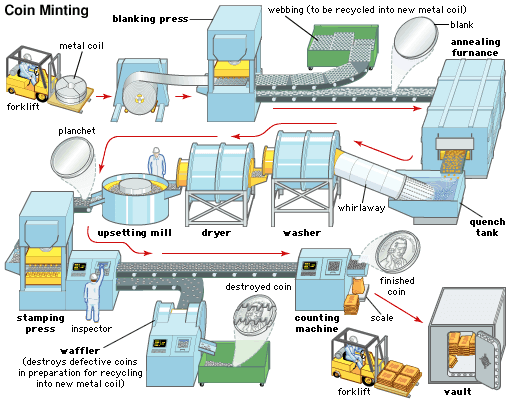

Zenziwa Kanjani Izinhlamvu zemali?

Izindlela ezisetshenziselwa ukwenza izinhlamvu zemali ziye zashintsha ngokuhamba kweminyaka. Izinhlamvu zemali zenziwa okokuqala embusweni wasendulo waseLidiya eminyakeni engaphezu kwezinkulungwane ezimbili edlule. Inqubo yokwenza izinhlamvu zemali zasendulo yayilula. Okokuqala, isigaxa esincane segolide, isiliva, noma ithusi sasifakwa ohlamvini lwemali efakwe endaweni eqinile njengetshe. Isisebenzi sabe sesithatha uhlamvu lwesibili lwemali, silubeke phezulu, bese silushaya ngesando esikhulu.

Amaminti enkathi ephakathi asebenzisa amadiski ayindilinga ensimbi akhiwe kusengaphambili kanye nomshini wokunyathelisa ngesikulufu ukuze enze izinhlamvu zemali. Nakuba lokhu kwakuyinqubo eyenziwa ngesandla, kwakulula futhi kwaveza ikhwalithi engaguquki kunenqubo yasendulo yokugaya.

Izinhlamvu zemali zesimanje zenziwe ngemishini yokunyathelisa ye-hydraulic efaka ngokuzenzakalelayo izikhala emshinini. Uma umshini usebenza ngokugcwele, umshini wokunyathelisa ungenza izinhlamvu zemali ezingaphezu kuka-600 ngomzuzu. Leli jubane liyadingeka ekusebenzeni okufana ne-United States Mint, okumele ikhiqize izigidigidi zezinhlamvu zemali njalo ngonyaka.

Nakuba le nqubo iyinkimbinkimbi ngenxa yokushintshashintsha okusetshenziselwa ukukhiqiza izigidi zezigidi zemali, kunezinyathelo ezimbalwa ezivamile ezisetshenziswa yi-mint emhlabeni wonke. I-Mint yase-United States iyi-mint enkulu kunazo zonke emhlabeni, futhi sizogxila enqubweni yayo yokukhiqiza.

1. Imayini Raw Materials

Inqubo yokugaya iqala ngokumbiwa kwezinto ezingavuthiwe. Izimayini ezivela kulo lonke elase-United States nasemhlabeni wonke zihlinzeka ngegolide, isiliva, ithusi, noma ezinye izinsimbi ezidingekayo. Insimbi eluhlaza etholakala kulezi zimayini iqukethe ukungcola okungamukeleki ngemali yemali.

Ngaphezu kwensimbi yezimayini ukuze kutholwe insimbi edingekayo, i-United States Mint iphinde isebenzisa insimbi egaywe kabusha etholwe kabusha emithonjeni ehlukahlukene. Le mithombo ihlanganisa izinhlamvu zemali ezingasakwazi "ukucutshungulwa" futhi ezikhishwayo ekujikelezeni. Kunalokho, zibuyiselwa ku-mint, lapho zigaywa kabusha zibe izinhlamvu zemali ezintsha.

2. Ukucwenga, Ukuncibilika, kanye Nokulingisa

Insimbi eluhlaza iyacwengwa ukuze isuse cishe konke ukungcola. Ezinye izinhlamvu zemali zidinga i-alloy yezinhlobo ezimbili noma ngaphezulu ezihlukene zezinsimbi. Insimbi ecwengiwe iyancibilika, futhi izinsimbi ezihlukene njengoba kudingwa yizicaciso ziyengezwa. Isibonelo, i-United States Mint yenza uhlamvu lwayo lwamasenti amahlanu kusuka kumaphesenti angu-75 ethusi namaphesenti angu-25 we-nickel alloy.

Uma ukuhlanzeka okufanele noma i-alloy kufinyelelwe, insimbi iphonswa ku-ingot. Lezi izinsimbi ezinkulu eziqukethe inani elifanele lensimbi njengoba kudingwa yi-mint. Insimbi ibhekwa kuyo yonke inqubo ukuze kutholakale ubumsulwa obufanele.

3. Ukugingqika

Inqubo yokugingqa i-ingot ekugqineni okufanele ingaba yinde futhi isebenze kanzima. Ingot igoqeka phakathi kwamarola amabili ensimbi aqinile alokhu esondelana futhi esondelana ndawonye. Le nqubo izoqhubeka kuze kube yilapho ingot igoqwa ibe umucu wensimbi owugqinsi olufanele lwemali eyenziwayo. Ukwengeza, inqubo yokugingqa ithambisa insimbi futhi iguqule isakhiwo samangqamuzana esivumela ukuthi ishaywe kalula futhi ikhiqize izinhlamvu zemali zekhwalithi ephezulu.

Uma i-alloy material, iyadingeka ukwenza i-anealing ngaphambi kokuyivala.

4. Ukungasho lutho

I-United States Mint isebenzisa amaroli ensimbi acishe abe ngamasentimitha angu-13 ububanzi futhi anesisindo esingamaphawundi ayizinkulungwane ezimbalwa. I-roll yensimbi ayilindi futhi ifakwe isicaba ukuze kususwe ukugoba enqubweni yokukhiqiza. Ibe isidluliswa emshinini okhipha amadiski ensimbi manje asewugqinsi nobubanzi obufanele bohlamvu lwemali olwenziwe.

5. Ukuphicaphica

Kuze kube manje, inqubo yokukhiqiza esetshenziselwa ukwenza izikhala zensimbi ingcolile futhi iqhutshwa endaweni enzima. Kungenzeka ukuthi izingcezu ezincane zensimbi zihlanganiswe nezikhala zemali. Umshini wokuphicaphica uhlukanisa izikhala ezinosayizi ngokufanelekile kunoma iyiphi into yangaphandle exutshwe nezikhala zemali.

6. Ukuhlanza nokuhlanza

I-mint ibe isidlulisa izimbobo zemali kuhhavini oshisayo ukuze athambise insimbi ukulungiselela ukushaywa. Izikhala zibe sezifakwa endaweni yokugeza ngamakhemikhali ukuze kukhishwe amafutha nokungcola okungenzeka kube phezu kohlamvu lwemali. Noma iyiphi impahla yangaphandle ingashumeka kuhlamvu lwemali ngesikhathi senqubo yokushaya, futhi kuzodingeka ukuthi ichithwe.

7. Ukucasula

Ukuze kuvikelwe idizayini ezohlabeka umxhwele ohlamvini lwensimbi olungenalutho, uhlamvu lwemali ngalunye olungenalutho ludlula emshinini onesethi yamarola eba mancane kancane futhi anikeze rimu lensimbi eliphakanyisiwe nhlangothi zombili zohlamvu lwemali olungenalutho. Le nqubo iphinde isize ekuqinisekiseni ukuthi uhlamvu lwemali olungenalutho luwububanzi obufanele ngakho luzoshaya kahle emshinini wokwenza imali. Ngemva kwalolu hlelo, uhlamvu lwemali olungenalutho manje lubizwa ngokuthi i-planchet.

8. Ukunyathela noma Ukushaywa

Manje njengoba amapulangwe eselungiswe kahle, athambekisiwe, futhi ahlanzwa, manje aselungele ukushaywa. Izinhlamvu zemali ezishaywe yibhizinisi zifakwa ngokuzenzakalelayo emshinini wokwenza imali ngenani elingafinyelela amakhulu amaningana ezinhlamvu zemali ngomzuzu. Izinhlamvu zemali zobufakazi ezenzelwe abaqoqi ziphakelwa ngesandla emshinini wokwenza imali futhi zithola okungenani iziteleka ezimbili uhlamvu lwemali ngalunye.

9. Ukusabalalisa

Izinhlamvu zemali eziphumelela ukuhlolwa sezilungele ukusatshalaliswa. Izinhlamvu zemali ezishaywe yibhizinisi zipakishwa ezikhwameni eziningi zokugcina bese zithunyelwa kubasabalalisi emhlabeni wonke. Izinhlamvu zemali eziqoqiwe zifakwa kuzibambi ezikhethekile nasemabhokisini futhi zithunyelwe ukuze zenze imali yabaqoqi emhlabeni jikelele.

Imininingwane:

Chofozaumshini wokuphonsa oqhubekayo.

Umshini wokugaya amashidi

Kunezinhlobo ezimbili zezigayo zokugaywa zokwenza amabha / izinhlamvu zemali, uhlobo lokuqala lomshini wokugoqa amashidi wenza indawo evamile, kulokhu, ngokuvamile udinga ukupholishwa kokugcina nge-tumbler polisher.

| Imodeli No. | HS-8HP | I-HS-10HP |

| I gama le-brand | I-HASUNG | |

| Amandla kagesi | 380V 50/60Hz, 3 izigaba | |

| Amandla | 5.5KW | 7.5KW |

| Irola | ububanzi 120 × ububanzi 210mm | ububanzi 150 × ububanzi 220mm |

| ubulukhuni | 60-61 ° | |

| Ubukhulu | 980×1180×1480mm | 1080x580x1480mm |

| Isisindo | cishe. 600kg | cishe. 800kg |

| Amandla | Ubukhulu bokujiya bukhuphuke ngo-25mm | Ubukhulu obukhulu be-Rolling bufika ku-35mm |

| Inzuzo | Uhlaka lufakwe uthuli ngogesi, umzimba umbozwe nge-chrome eqinile yokuhlobisa, futhi isembozo sensimbi engagqwali sihle futhi siyasebenza ngaphandle kokugqwala. isivinini esisodwa / isivinini esiphindwe kabili | |

| Ngemva Kwesevisi Yewaranti | Ukusekelwa kobuchwepheshe bevidiyo, Ukusekelwa ku-inthanethi, izingxenye eziyisipele, ukugcinwa kwensimu kanye nesevisi yokulungisa | |

I-Tungsten Steel Mirror Surface Rolling Mill

Olunye uhlobo i-tungsten steel material roller mirror surface sheet rolling mill. Ngalolu hlobo lomshini wokugoqa, uzothola ishidi elingaphezulu kwesibuko.

| Imodeli No. | I-HS-M5HP | I-HS-M8HP | ||

| I gama le-brand | I-HASUNG | |||

| Amandla kagesi | 380V; 50/60hz 3 Izigaba | |||

| Amandla | 3.7kw | 5.5kw | ||

| Usayizi we-Tungsten Roller | ububanzi 90 × ububanzi 60mm | ububanzi 90 × ububanzi 90mm | ububanzi 100 × ububanzi 100mm | ububanzi 120 × ububanzi 100mm |

| Ukuqina kweRoller | 92-95 ° | |||

| Okubalulekile | ngaphandle kwe-tungsten steel billet | |||

| Ubukhulu | 880×580×1400mm | 980×580×1450mm | ||

| Isisindo | cishe. 450kg | cishe. 500kg | ||

| Izici | Ngokugcoba; i-gear drive; Ukujiya kweshidi eligoqayo 10mm, thinnest 0.1mm; extruded sheet metal surface mirror effect; ukufafaza okuyimpushana ohlakeni, ukuhlobisa okuqinile kwe-chrome plating, insimbi engagqwali ikhava, enhle futhi ephathekayo ngeke ibe nokugqwala. | |||

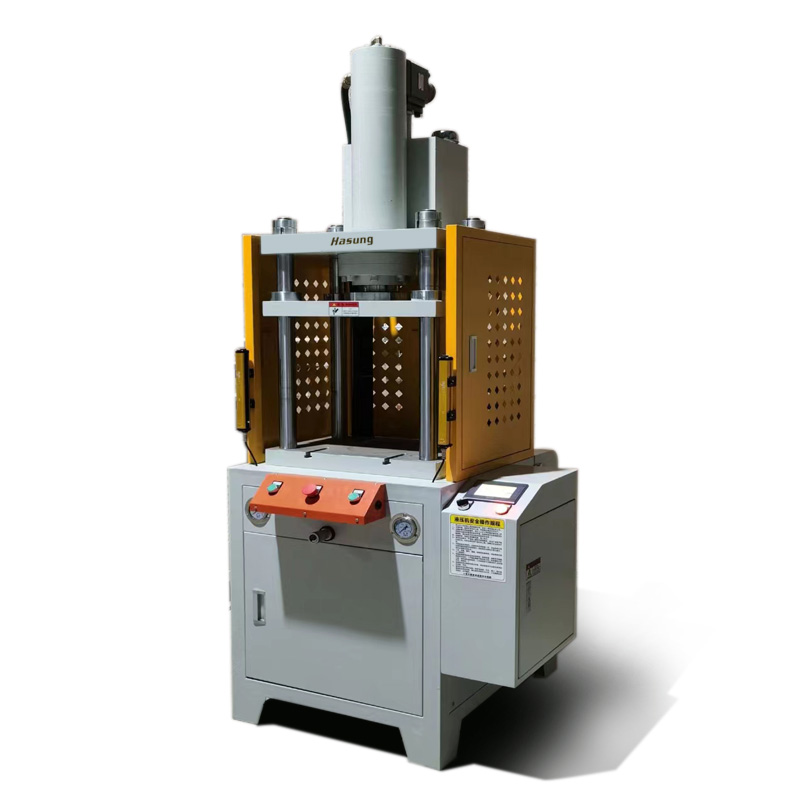

IHYDRAULIC COIN BLANKING PRESS

Inqubo Yokungasho lutho

20 Ton Hydraulic Coin Cutting / Blanking Press

40 Ton Hydraulic Cutting & Embossing Cindezela

Le mishini yokusika i-hydraulic isika ishidi legolide nesiliva elingenalutho elicutshungulwa ngemva kokugoqwa. Ishidi elingenalutho lisikwa libe elifiselekayo elibunjwe libe yindilinga, elingunxande, elilengayo elilengayo njll. Ukuhlinzeka ngenqubo yokusika ama-dies emva kwalokho izikhala sezilungele ukugaywa zibe yi-hydraulic stamping press.

Izinzuzo ze-hydraulic cutting power press machine.

Ilungele ukusika izikhala zegolide nezesiliva,

Sika izikhala emiphethweni ecacile ukuze uthole imiphumela engcono,

Ukusebenza kwamahhala kanye nemodi ekabili esebenza ngonyawo nokushintsha,

Uhlelo lokumisa lokuqhubeka nokusika,

Uhlelo lokulungisa lokufa olunekhabethe elilula lediphozi,

Ukulungiswa kokusika ukuze kukhiqizwe ngokushesha.

Ifakwe umkhombe ongenalutho, kulula ukuqoqa izinto zokwakha.

Imingcele Yezobuchwepheshe

| Imodeli No. | I-HS-20T | I-HS-40T | I-HS-100T |

| Ngokuzisholo | 20 ton | 40 ton | 100 ton |

| I-stroke enkulu | 300mm | 350mm | 400mm |

| Ukuvula ubude | 500mm | 400mm | 600mm |

| Isivinini esehla | 160mm | 180mm | 120mm |

| Isivinini esikhuphukayo | 150mm | 160mm | 120mm |

| Indawo esebenzayo | 600*500mm | 550 * 450mm | 700*600mm |

| Ukuphakama kwetafula kusuka phansi | 850 mm | 850 mm | 850 mm |

| Amandla kagesi | 380V 3 izigaba | 380V 3 izigaba | 380V 3 izigaba |

| Amandla emoto | 3.75kw | 3.75kw | 5.5kw |

| Isisindo | 1300KG | 860KG | 2200KG |

100 amathaniI-Hydraulic Coin Embossing Cindezela

150 Ton Hydraulic Coin Embossing Press

200 Ton Hydraulic Coin Embossing Press

300 Ton Hydraulic Gold and Silver Coining Press

150 amathani hydraulic uhlamvu embossing press embossing ezifanele ukwenza zemali kufika 50 amagremu esiliva. Umshini wokunyathelisa ulungele ukusebenza nge-manual kanye nemodi yokusebenza okuzenzakalelayo komjikelezo owodwa. Itholakala nge-auto coin ejecting mechanisum. Umshini wokunyathelisa unganikezwa ngamathani ahlukahlukene afana namathani angama-80, amathani ayi-100, amathani ayi-150, amathani angama-200 ngokwesidingo sakho.

Umshini wokucindezela uhlamvu lwemali lwamathani angu-300 wegolide nesiliva ophelele ngesilawuli se-PLC esihlelekayo semivimbo eminingi esigabeni sokugcina. Umshini wokunyathelisa ufakwe i-ejector cylinder yokukhishwa okuzenzakalelayo kohlamvu lwemali ukuze lukhishwe kalula ngaphandle kokushaywa ngesando. Lesi sici sinikeza isiphetho esingcono sokugcina sohlamvu lwemali. Lo mshini wokunyathelisa we-hydraulic coining ulungele ukwenza izinhlamvu zemali zegolide nesiliva ukusuka ku-1.0 igremu ukuya ku-100.0 amagremu ngesisindo futhi unikwa amandla ngogesi ongu-10.0 HP (7.5KW) futhi uhlinzekwa uphelele ngogesi ofanelekile kanye nephaneli yokulawula. Lo mklamo womshini wokuhlanganisa uhlanganisa ukulawula kokulungiswa kwengcindezi ngesibali sikhathi ukuze ulungise isikhathi sokucindezela sokugcina ngaphambi kokushaywa unhlangothi. Ingasetshenziswa ngokulawula inkinobho yokusunduza kanye nangemodi yomjikelezo owodwa ozenzakalelayo.

Ngaphandle komshini wokunyathelisa we-hydraulic coining kanye ne-precision sheet rolling mill, udinga umshini wokuncibilikisa ongenisayo noma umshini wokuphonsa oqhubekayo wokwenza amashidi egolide nesiliva, umshini wokusika ibha yegolide nesiliva kanye nemishini yokupholisha isidlidlizi edingekayo ukuze umise isitshalo sokwenza uhlamvu lwesiliva oluphelele lwegolide nesiliva.

Imingcele Yezobuchwepheshe

| Imodeli No | I-HS-100T | I-HS-200T | I-HS-300T |

| Amandla kagesi | 380V, 50/60Hz | 380V, 50/60Hz | 380V, 50/60Hz |

| Amandla | 4KW | 5.5KW | 7.5KW |

| Ubukhulu. ingcindezi | 22Mpa | 22Mpa | 24Mpa |

| Ukushaywa kwetafula lomsebenzi | 110mm | 150mm | 150mm |

| Ubukhulu. ukuvula | 360 mm | 380mm | 380mm |

| Ithebula lokusebenza phezulu ngesivinini sokunyakaza | 120mm/s | 110mm/s | 110mm/s |

| Ithebula lomsebenzi ijubane lokubuyela emuva | 110mm/s | 100mm/s | 100mm/s |

| Usayizi wethebula lomsebenzi | 420*420mm | 500*520mm | 540*580mm |

| Isisindo | 1100kg | 2400kg | 3300kg |

| Isicelo | ubucwebe negolide ibha, zemali logo stamping | ||

| Isici | I-Normal / Servo motor yenketho, inkinobho sebenzisa / Simens PLC Control System ukuze ukhethe | ||

Izinhlamvu zemali Ezizenzakalelayo Ezigcwele Zokwenza Uhlelo Lokukhiqiza

Ungabhanga nge-Hasung ukuze ikunikeze isisombululo esisodwa somugqa wokwenza uhlamvu lwemali. Iphakheji yokukhiqiza ihlanganisa ukuqondisa okusendaweni, imishini yokwenza uhlamvu lwemali, kanye nonjiniyela ukukusiza ukukala ngenqubo. Onjiniyela bethu babambe iqhaza ocwaningweni lwenqubo yokwenza uhlamvu lwegolide futhi basebenze njengabaxhumanisi bezobuchwepheshe beminti emikhulu eyaziwayo.

U-Hasung ugxile ekuxazululeni izinkinga zokwenziwa kohlamvu lwemali ngenkathi enikeza imiyalelo yesinyathelo nesinyathelo ngezinsimbi eziyigugu. Iminyaka engu-20+ besihamba phambili emshinini wokwenza uhlamvu lwegolide nesiliva, sinesevisi yobunjiniyela obuchwepheshile, ukuqeqeshwa esizeni, kanye nokwesekwa kobuchwepheshe Izinhlelo Zethu.

Isikhathi sokuthumela: Jul-04-2022