Imishini Yokucwenga Igolide: Leyo mishini ebalulekile enqubweni yokucwenga igolide

Igolide seliwuphawu lwengcebo nokuchuma amakhulu eminyaka, futhi ukubaluleka kwalo kwenze kwaba yimpahla efunwa kakhulu kuzo zonke izigaba zokuphila. Inqubo yokucwengisiswa kwegolide ibalulekile ukuze kuqinisekiswe ubumsulwa kanye nekhwalithi yalo, futhi izindawo zokucwenga igolide zidlala indima ebalulekile kulokhu. Ukuze kwenziwe inqubo eyinkimbinkimbi yokucwenga igolide, kudingeka imishini eminingi ukuze kuqinisekiswe ukusebenza kahle nokunemba kwenqubo yokucwenga. Kulesi sihloko, sizokwethula izinto eziyisisekelo ezidingekayo endaweni yokucwenga igolide, okuhlanganisa imishini yokwenza ama-flake egolide, ama-atomizer empushana yegolide, izinhlelo zokucwenga igolide, iziko lokuncibilikisa igolide, i-metal granulator, kanye ne-golden bar vacuum casting, umshini wokugxiviza uphawu, njll.

Umshini wokwenza ama-flakes egolide:

Isinyathelo sokuqala enqubweni yokucwenga igolide siwukuthola igolide lisesimweni salo esingavuthiwe, ngokuvamile eliba yitshe legolide noma izingcezu zegolide. Ukuze kuqalwe inqubo yokucwenga, igolide lidinga ukuhlukaniswa libe izingcezu ezincane, izingcezu ezilawulekayo. Yilapho umenzi we-sequin engena khona. futhi kulula ngenjongo yokucwiliswa ngamakhemikhali. Umshini uklanyelwe ukuncibilika futhi uthole impahla yegolide eluhlaza ibe ama-flakes ama-alloy egolide amancane, wakhe ama-flakes egolide angaphinde acutshungulwe ohlelweni lokucwenga.

I-atomizer eyimpuphu yegolide:

Ngaphandle kwama-flakes egolide, enye inketho ukuguqula izinto ezingavuthiwe zibe izimpusha zegolide. I-atomizer yempushana yegolide iyisisetshenziswa esibalulekile kule nqubo, inesibopho sokuguqula izinto zengxube yegolide zibe yimpushana (imvamisa usayizi wemeshi oyi-100) ngenqubo ye-atomization. Lokhu kuhilela ukukhipha igolide elincibilikisiwe egumbini lapho liqina libe yizinhlayiyana ezincane, kukhiqizwe impushana yegolide yekhwalithi ephezulu ebalulekile esigabeni sokucwengisisa esilandelayo.

Isistimu yokucwenga igolide:

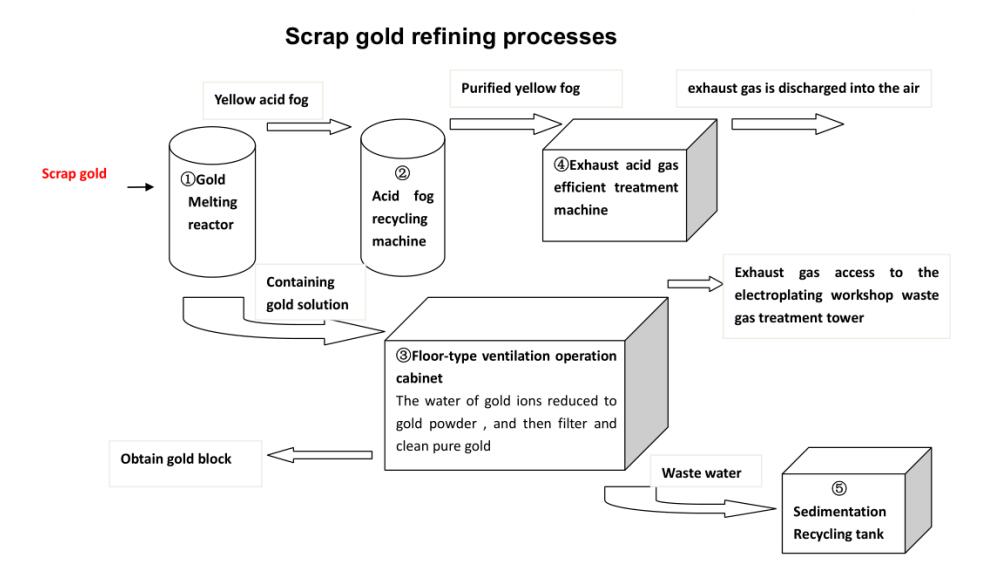

Enhliziyweni yanoma iyiphi indawo yokucwenga igolide kunesimiso sokucwenga igolide, esinomthwalo wemfanelo wokuhlanza igolide nokususa noma yikuphi ukungcola noma ukungcola. Isistimu ngokuvamile iqukethe izingxenye ezihlukahlukene, okuhlanganisa amathangi amakhemikhali, izihlungi, namadivayisi okwehlisa izinga, konke okusebenzisana ukuze kuhlukanise igolide elimsulwa kwezinye izinsimbi nokungcola. Amasistimu okucwenga asebenzisa izinqubo zamakhemikhali ezifana ne-aqua regia noma i-electrolysis ukuze kuzuzwe ubumsulwa begolide obudingekayo, kuqinisekiswe ukuthi ihlangabezana nezindinganiso zomkhakha ukuze zisetshenziselwe ukuthengisa. Ngokuvamile izindleko zomugqa wokukhiqiza zincike kumthamo wesicelo sosuku, isistimu izoklanywa futhi ifakwe umthamo oceliwe. Lolu hlelo lokucwenga igolide ikakhulukazi luhlanganisa uhlelo lokusabela kwamakhemikhali, uhlelo lokuhlukanisa, uhlelo lokuhlanza amanzi endle, imigudu yokuhlanza ipayipi nentuthu, njll.

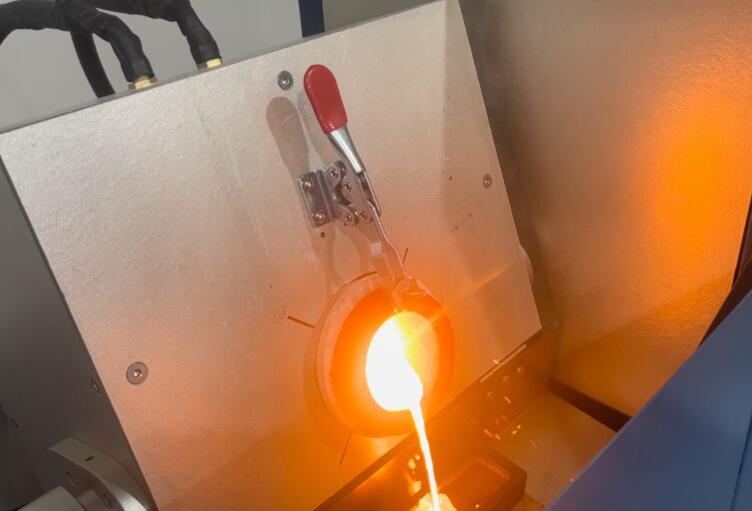

Isithando somlilo esincibilikisa igolide:

Ukuze kuqhutshekwe kucutshungulwe isipontshi segolide ekucwengisweni kwegolide, igolide lesipontshi kufanele lincibilikiswe libe yisimo esincibilikisiwe. Yilapho isithando somlilo segolide singena khona. Isithando somlilo siklanyelwe ukushisisa igolide lize lincibilike, okwenza kube lula ukuliphatha futhi lihlukanise nanoma yikuphi ukungcola okusele. Igolide elincibilikisiwe lingabese lithelwa esikhunjeni ukuze kwakhiwe izigxobo zegolide noma ezinye izinhlobo ezidingekayo ngezinjongo zokuhweba.

Metal granulating umshini:

Ukuze uthole amashothi egolide afanayo okulula futhi okunembile kukalwa izikali zokukala kanye nesisindo sokugcina esinembile sezinjongo zamabha egolide, i-metal granulator iwumshini wephuzu elibalulekile lokudlala indima. Ncibilikisa igolide futhi uthole izinhlamvu zegolide emshinini wokwenza i-granulating. Inezinhlobo ezimbili kuyilapho eyodwa ingumshini wokudonsela phansi amandla adonsela phansi, enye i-vacuum granulator.

Ukukhipha i-vacuum yebha yegolide:

Ngemuva kokuthi igolide selicwengisisiwe futhi lincibilikisiwe njengamashothi egolide, livamise ukujikijelwa emimoyeni ethile noma amafomu ukuze kube lula ukuliphatha nokuthutha. Umshini wokuphonsa we-vacuum wegolide usetshenziselwa ukufeza lokhu njengoba uphonsa ngokunembile igolide elincibilikisiwe esikhunjeni ngaphansi kwezimo ze-vacuum. Le nqubo iqinisekisa ukuthi amabha egolide akhiwa ngokunemba okuphezulu kanye nekhwalithi, alungele amadili emakethe.

Umshini wokunyathelisa we-logo we-hydraulic press:

Ngokuvamile abathengisi begolide bangathanda ukwenza ilogo negama labo kumabha egolide, ngakho umshini wokugxiviza amalogo wenza umsebenzi omuhle kakhulu kulokhu. Ngamasayizi ahlukene wemigoqo kanye nokufa okuhlukile.

Isistimu yokumaka i-dot peen:

Ibha yegolide ivamise ukuba nenombolo yayo ye-serial efana nenombolo ye-ID, ngakho ngokuvamile abenzi begolide basebenzisa isistimu yokumaka ichashazi ukuze baqophe izinombolo ze-serial kuyo yonke ingot yegolide.

Kafushane, indawo yokucwenga igolide idinga uchungechunge lwemishini ekhethekile ukwenza inqubo eyinkimbinkimbi yokucwenga igolide. Kusukela ekuphuleni impahla yegolide eluhlaza ibe ama-flakes, kuye ekuyiguquleni ibe yimpushana ecolekileyo, futhi ekugcineni ihlanzwe futhi iphonswe esimweni oyifunayo, umshini ngamunye udlala indima ebalulekile ekuqinisekiseni ikhwalithi nokuhlanzeka kwegolide elicwengiweyo. Ngokutshala imali emishinini nasezinsizeni ezifanele, izindawo zokuhluza igolide zingakwazi ukwenza lula ukusebenza futhi zikhiqize imikhiqizo yegolide yekhwalithi ephezulu ehlangabezana nesidingo semakethe.

Ungaxhumana no-Hasung ngazo zonke lezi zisetshenziswa zebhizinisi lakho legolide. Uzothola imishini ehamba phambili nomkhiqizi wangempela onamanani amahle namasevisi.

Isikhathi sokuthumela: May-21-2024