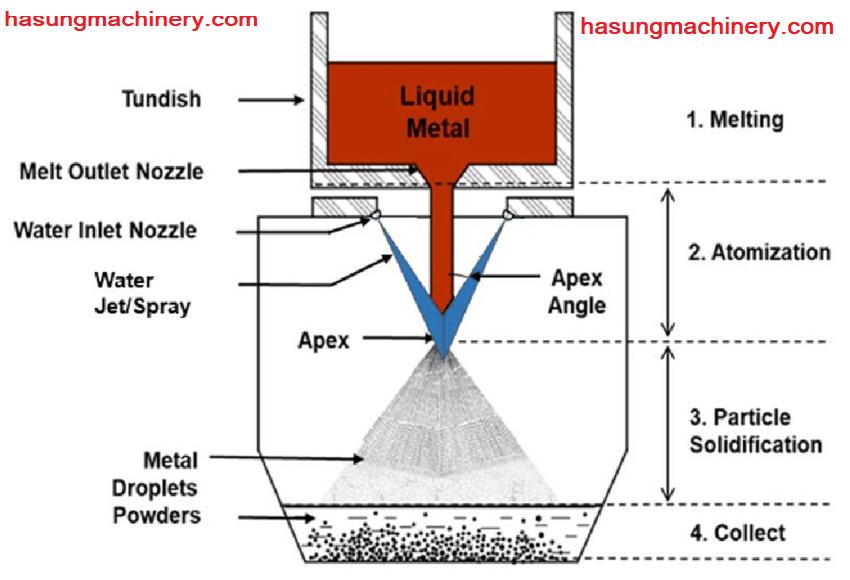

Lo mshini usetshenziselwa ikakhulukazi ukwenza i-metal powder noma i-granule ku-atomization. igumbi nge-high pressure water atomization method emva kwensimbi noma ingxubevange yensimbi. zincibilike ngaphansi kwendawo yokuvikela igesi noma indawo yomoya evamile. Izindleko zokusebenza zomshini kanye nezindleko zokukhiqiza impushana ziphansi. Isisetshenziswa Se-Metal Powder Water Atomization siwuhlobo lwesu lokulungela impushana lapho insimbi noma uketshezi oluhlangene luhlukaniswa lube ubuhlalu obuncane ngokuzulazula koketshezi olusheshayo (i-atomization medium) noma izindlela ezihlukile, ezilandelwa ngokunqwabelana zibe yimpushana eqinile. Noma iyiphi into engabumba uketshezi ingaba yi-athomu futhi ibe yimpuphu. Ingcindezi ephezului-atomization yamanziamasu angenza ngemali nangempumelelo i-MIM yensimbi ye-amalgam powder, impushana yensimbi ephathwayo ehlukile, impushana yensimbi esheshayo, impushana yensimbi ebalulekile, impushana ehlanganiswe nethusi, kanye nePowder eyinhlanganisela enkulu, njalo njalo. Okuvame ukusetshenziswa kakhulu yi-gas atomization Equipment kanye ne-water atomization Equipment. Ngesikhathi esichithwe inqubo yokuletha impushana ye-athomu, ncibilikisa izinto zensimbi ezingacwengekile kuketshezi lwe-amalgam olufanelekile (ikakhulu lushiswe kakhulu ngo-100-150 ℃) ngesifudumezi sikagesi noma isifudumezi sokwamukela, bese emva kwalokho sifakwe ku-tundish phezu kwe-atomizing spout. Uketshezi oluyingxube luphuma embotsheni yokuchitheka engxenyeni engezansi ye-tundish, futhi uma ludlula ku-spout, lushintshwa lube ubuhlalu obucolekileyo lapho luzwa amandla omoya osheshayo noma umfudlana wamanzi. Amaconsi ane-athomu aqiniswa ngokushesha abe yimpuphu ehlanganisiwe egumbini elivaliwe le-atomizing. Ikakhulu, izinhlayiya ze-athomu ye-athomu yegesi eyimpuphu iyindilinga, inokuqukethwe kwe-oxygen ephansi (ngaphansi kuka-100 × 10), futhi ingenziwa ngokuqondile ibe izinto eziminyene ngokusungula i-thermoforming, (ngokwesibonelo, ukuminya kwe-isostatic okushisayo). Izinhlayiya zempushana ye-athomu yamanzi ingxenye enkulu ziyizimo ezingalindelekile ezinokuqukethwe kwe-oxygen ephezulu (ngaphezulu kuka-600 × 10) futhi kufanele zifutheke. Inokucindezelwa okukhulu futhi ingakhanywa ezingxenyeni zemishini.

Isimiso sokusebenza

Indlela ehilelekile ekuletheni impushana yensimbi ngegiya lokucubungula i-atomization yamanzi inomlando omude. Ezikhathini zasendulo, abantu babethululela insimbi ewuketshezi emanzini bese beyiqhumisa ibe izinhlayiya zensimbi, ezazisetshenziswa njengezingxenye ezingalungisiwe zokwakha insimbi; kuze kube manje, kunabantu abathulula umthofu owuketshezi ngokuqondile emanzini ukuze benze amashothi omthofu. Isu lokushaya i-atomization yamanzi lisetshenziselwa ukwenza impushana eqinile. Umhlahlandlela womjikelezo ulingana nalokhu okukhulunywe ngakho ngaphambili okuvumela amanzi ukuthi aqhumise insimbi ewuketshezi, nokho ukukhiqiza okulimazayo kuye kwathuthukiswa kakhulu. Ukwenza inhlanganisela yempushana emahhadla ngegiya lokupompa le-atomization yamanzi, igolide elimahhadla kufanele lincibilikiswe ku-heater kuqala, futhi igolide eliwuketshezi kufanele lishiswe kakhulu cishe ngama-degree angu-50. Khona-ke, ngaleso sikhathi, ifakwe ku-tundish. Qala i-siphon yamanzi enengcindezi ephezulu ngaphambi kokuthi kufakwe uketshezi olusagolide, bese uvumela igajethi ye-atomization yamanzi enomfutho ophezulu iqale ucezu lokusebenza. Uketshezi olusagolide ku-tundish ludlula kubha bese lungena ku-atomizer nge-spout yokuchitheka engxenyeni engezansi yenqwaba. I-atomizer iyigiya elibalulekile ekuletheni impushana yegolide eqinile enenkungu yamanzi edonsa kanzima. Imvelo ye-atomizer ikhonjwa ngobungoti obulimazayo bempushana yensimbi. Ngaphansi komsebenzi wamanzi anomfutho ophezulu we-atomizer, uketshezi olusagolide luhlephuka lube ubuhlalu obucolekileyo, obuwela oketshezini olupholile olukugajethi, bese lusimende ngokushesha lube yimpushana ye-amalgam. Enqubweni evamile ye-atomization yamanzi anomfutho ophezulu wokuletha impushana yensimbi, impushana yensimbi ingaqoqwa njalo, kodwa inani elincane lempushana yensimbi lizolahleka emanzini ane-athomu. Ukuze uthole i-atomization yamanzi enomfutho ophezulu, into ye-athomu ifakwe kugajethi ye-atomization, isheshisiwe, ihlungwe, (uma ibalulekile, ingase yomiswe kahle, ngokuvamile ihanjiswe ngokuqondile ohlelweni olulandelayo.) ukuze uthole i-Alloy powder emihle, kuyoba khona akukho ukushoda kwempushana ye-amalgam kuwo wonke umjikelezo.kodwa inani elincane lempushana yensimbi lizolahleka namanzi ane-athomu. Ukuze uthole i-atomization yamanzi enomfutho ophezulu, into ye-athomu ifakwe kugajethi ye-atomization, isheshisiwe, ihlungwe, (uma ibalulekile, ingase yomiswe kahle, ngokuvamile ihanjiswe ngokuqondile ohlelweni olulandelayo.) ukuze uthole i-Alloy powder enhle, kuyoba khona akukho ukushoda kwempushana ye-amalgam kuwo wonke umjikelezo.kodwa inani elincane lempushana yensimbi lizolahleka namanzi ane-athomu. Ukuze uthole i-atomization yamanzi enomfutho ophezulu, into ye-athomu ifakwe kugajethi ye-atomization, isheshisiwe, ihlungwe, (uma ibalulekile, ingase yomiswe kahle, ngokuvamile ihanjiswe ngokuqondile ohlelweni olulandelayo.) ukuze uthole i-Alloy powder enhle, kuyoba khona akukho ukuntuleka kwe-amalgam powder kuwo wonke umjikelezo.

Ukuhlelwa okuphelele kwe-metal powder water atomization hardware kuhlanganisa izingxenye ezihambisanayo: Ingxenye encibilikayo: Ungakhetha isithando somlilo esincibilikisa imvamisa emaphakathi noma isithando somlilo esincibilikisa insimbi esinemvamisa ephezulu. Umthamo wesithando somlilo uncike kumthamo wokucubungula we-powder yensimbi. Ungakhetha isithando somlilo esingama-50 kg noma isithando somlilo esingama-20 kg. Ingxenye ye-Atomization: Le ngxenye yemishini iyimishini engekho ejwayelekile, okufanele iklanywe futhi ihlelwe ngokuvumelana nezimo zesayithi lomkhiqizi, ikakhulukazi kuhlanganise ne-tundish: lapho i-tundish ikhiqizwa ebusika, idinga ukushiswa kwangaphambili; I-Atomizer: I-atomizer ithinta amanzi anomfutho ophezulu wempompi wamanzi womfutho ophezulu ngesivinini esinqunywe kusengaphambili kanye ne-engeli ngokumelene noketshezi olusagolide olusuka ku-tundish, iwaphule abe amaconsi ensimbi. Ngaphansi kwengcindezi yepompo efanayo, inani lempushana yensimbi enhle ngemva kwe-atomization lihlobene nokusebenza kahle kwe-atomizer; i-atomization cylinder: indawo lapho i-alloy powder yenziwa i-atomu, ichotshozwe, ipholile futhi iqoqwe. Ukuze uvimbele ukuthi i-superfine alloy powder ingalahleki namanzi, i-alloy powder elungisiwe kufanele ivunyelwe ukuba ime isikhathi esithile ngemva kokukhishwa kwe-atomization, bese ifakwa ebhokisini lokwamukela impushana. Ingxenye ye-post-processing: ibhokisi lokuqoqa impushana: isetshenziselwa ukuqoqwa kwe-athomu ye-alloy powder, ukuhlukaniswa nokususwa kwamanzi amaningi; isithando somlilo: ukomisa i-alloy powder emanzi ngamanzi; umshini wokuhlola: ukuhlola i-alloy powder, I-coarser alloy powder engahlangabezani nokucaciswa ingasetshenziswa njengento yokuncibilika kabusha ukuze incibilike futhi i-athomu.

Imishini ye-atomization yamanzi eyimpuphu ye-ultra-high inezici ezilandelayo

I-1-Ingasetshenziselwa izinsimbi eziningi nezimpushana ezihlanganisiwe, futhi izindleko zokudala ziphansi.

I-2-Ingakwazi ukuhlela i-subspherical powder noma i-sporadic powder.

3-Ngenxa yokushesha usimende futhi akukho ukuhlukaniswa, izimpushana eziningi ezihlukile ze-amalgam zingalunga.

4-Usayizi we-molecule ye-powder bungafika lapho kudingeka khona ngokushintsha uhlelo lokufafaza.

Ihlinzeka ngekhwalithi yensimbi yokusakaza

Ngolwazi Olwengeziwe Sicela

Sithumele I-imeyili :-info@hasungmachinery.com sales@hasungmachinery.com

Iwebhusayithi:- www.hasungcasting.comhttps://hasungmachinery.com/

Isikhathi sokuthumela: Jun-30-2022