I-atomizer Yamanzi Ye-Metal Powder Yensimbi Eyigugu YePlatinum Palladium

Ipharamitha yezobuchwepheshe

| Imodeli No. | I-HS-MI4 | I-HS-MI10 | I-HS-MI20 |

| Amandla kagesi | 380V 3 Izigaba, 50/60Hz | ||

| Ukunikezwa kwamandla kagesi | 15KW | 25KW | 40KW |

| I-Max Temp. | 2100°C | ||

| Isikhathi Sokuncibilika | 3-5 Amaminithi. | 5-8 Min. | 5-8 Min. |

| Ukusanhlamvu Okusanhlamvu | 80#-200#-400#-500# | ||

| Ukunemba Kwesikhashana | ±1°C | ||

| Amandla (Pt) | 4kg | 10kg | 30kg |

| Iphampu yeVacuum | (uyazikhethela) | ||

| Isicelo | Igolide, isiliva, ithusi, ingxubevange; I-Platinum(Uma uthanda) | ||

| Indlela yokusebenza | Ukusebenza kokhiye owodwa ukuqedela yonke inqubo, uhlelo lwe-POKA YOKE olungenangqondo | ||

| Isistimu yokulawula | I-Taiwan Weinview + Siemens PLC uhlelo lokulawula oluhlakaniphile | ||

| I-Shielding Gas | I-nitrogen/Argon | ||

| Uhlobo lokupholisa | I-water chiller (Ithengiswa ngokwehlukana) | ||

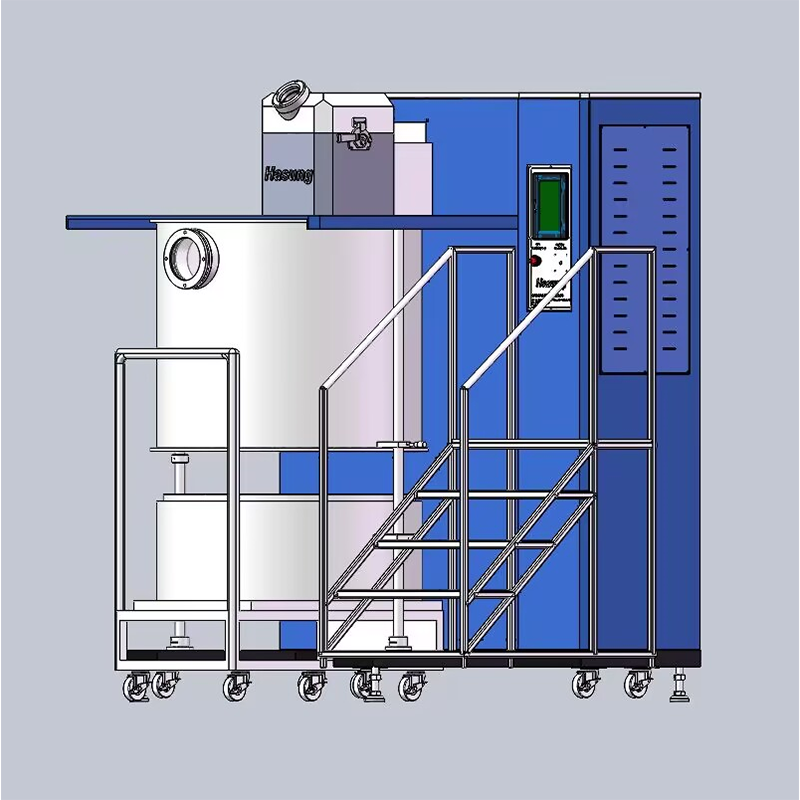

| Ubukhulu | 1180x1070x1925mm | 1180x1070x1925mm | 3575*3500*4160mm |

| Isisindo | cishe. 460kg | cishe. 560kg | cishe. 2150kg |

| Iphampu Yamanzi Yokucindezela Okuphezulu | kuhlanganisiwe | ||

Izici

I-HS-MI1 iwumndeni wama-atomizer amanzi aklanyelwe ukukhiqiza izimpushana zensimbi ezinomumo ongajwayelekile, ukuze zisetshenziswe ezimbonini, kumakhemikhali, ekunamathiseleni kokunamathisela, izihlungi ze-resin, i-MIM nezinhlelo zokusebenza ze-sintering.

I-atomizer isekelwe esithandweni sokungeniswa, esisebenza ekamelweni elivaliwe ngaphansi kwesimo sokuzivikela, lapho insimbi encibilikisiwe ithululelwa khona futhi ishaywe yi-jet yamanzi anomfutho ophezulu, ekhiqiza izimpushana ezinhle futhi ezikhishwe yi-deoxidized.

Ukushisa kokungeniswa kuqinisekisa ukuhlangana okuhle kakhulu kokuncibilika ngenxa yesenzo sokunyakaziswa kazibuthe ngesikhathi sesigaba sokuncibilika.

Iyunithi yokufa ifakwe ijeneretha yokungenisa eyengeziwe, evumela ukuqalisa kabusha umjikelezo esimweni sokuphazamiseka komjikelezo.

Kulandela izinyathelo zokuncibilika kanye ne-homogenization, insimbi ithululelwa iqonde ngesistimu yomjovo ebekwe endaweni engezansi ye-crucible (nozzle).

Imifudlana eminingi yamanzi anengcindezi ephezulu ihloswe futhi igxile kugongolo lwensimbi ukuze kuqinisekiswe ukuqina kwe-alloy esheshayo ngendlela yempushana.

Izinguquko zenqubo yesikhathi sangempela njengezinga lokushisa, ukucindezela kwegesi, amandla okungenisa, okuqukethwe kwe-oksijini ppm ekamelweni nokunye okuningi, kuboniswa kokubili ngefomethi yezinombolo nesithombe kusistimu yokuqapha ukuze kuqondwe ngokunembile umjikelezo wokusebenza.

Isistimu ingasebenza ngesandla noma ngemodi ezenzakalelayo ngokuphelele, ngenxa yokuhleleka kwayo yonke isethi yemingcele yenqubo ngokusebenzisa isixhumi esibonakalayo sesikrini esithintwayo esisebenziseka kalula.

Inqubo Yokwenza I-Metal Powder By Water Atomization Pulverizing Equipment

Inqubo yokwenza impushana yensimbi ngamanzi e-atomization pulverizing imishini inomlando omude. Ezikhathini zasendulo, abantu babethela insimbi encibilikisiwe emanzini ukuze iqhume ibe izinhlayiya zensimbi ezicolekile, ezazisetshenziswa njengezinto zokusetshenziswa ekwenzeni insimbi; kuze kube manje, kusekhona abantu abathela umthofu oncibilikisiwe ngokuqondile emanzini ukuze benze ama-pellets omthofu. . Ukusebenzisa indlela ye-atomization yamanzi ukwenza i-coarse alloy powder, umgomo wenqubo uyafana noketshezi lwensimbi olubalwe ngenhla, kodwa ukusebenza kahle kwe-pulverization kuye kwathuthukiswa kakhulu.

Imishini yokuphehla i-atomization yamanzi yenza i-coarse alloy powder. Okokuqala, igolide elimahhadla liyancibilika esithandweni. Uketshezi lwegolide oluncibilikisiwe kufanele lushiswe ngamadigri angaba ngu-50, bese luthululelwa ku-tundish. Qala iphampu yamanzi anomfutho ophezulu ngaphambi kokuba kujovwe uketshezi olusagolide, bese uvumela idivayisi ye-athomu yamanzi enomfutho ophezulu iqale ucezu lokusebenza. Uketshezi olusagolide ku-tundish ludlula engomeni bese lungena ku-atomizer ngombhobho ovuzayo ongezansi kwe-tundish. I-Atomizer iyisisetshenziswa esibalulekile sokwenza i-coarse gold alloy powder ngenkungu yamanzi enengcindezi ephezulu. Izinga le-atomizer lihlobene nokusebenza kahle kokuchotshozwa kwempushana yensimbi. Ngaphansi kwesenzo samanzi anomfutho ophezulu we-atomizer, uketshezi olusagolide luhlala luhlephuka lube amaconsi amahle, awela oketshezini olupholile ocingweni, bese uketshezi luqina lube yimpushana yengxubevange. Enkambweni yendabuko yokwenza i-powder yensimbi nge-atomization yamanzi e-high-pressure, i-powder yensimbi ingaqoqwa ngokuqhubekayo, kodwa kunesimo sokuthi inani elincane le-powder yensimbi lilahlekile ngamanzi a-atomizing. Enkambweni yokwenza i-alloy powder nge-high-pressure water atomization, umkhiqizo we-athomu ugxiliswa kudivayisi ye-atomization, ngemva kwezulu, ukuhlunga, (uma kunesidingo, ungomiswa, ngokuvamile uthunyelwa ngqo kwinqubo elandelayo.), ukuthola I-alloy powder enhle, akukho ukulahlekelwa kwe-alloy powder kuyo yonke inqubo.

Isethi ephelele yemishini yokucwenga i-atomization yamanzi Izinto zokwakha i-alloy powder ziqukethe lezi zingxenye ezilandelayo:

Ingxenye yokuncibilika:isithando somlilo sensimbi esincibilikisa imvamisa emaphakathi noma isithando somlilo esincibilikisa insimbi esinezinga eliphezulu singakhethwa. Umthamo wesithando somlilo unqunywa ngokusho komthamo wokucubungula we-powder yensimbi, futhi isithando somlilo esingama-50 kg noma isithando somlilo esingama-20 kg singakhethwa.

Ingxenye ye-Atomization:Imishini kule ngxenye iyimishini engeyona ejwayelekile, okufanele yakhelwe futhi ihlelwe ngokuya ngemibandela yendawo yomkhiqizi. Kukhona ikakhulukazi ama-tundishes: lapho i-tundish ikhiqizwa ebusika, idinga ukushiswa; I-Atomizer: I-atomizer izovela kumfutho ophezulu Amanzi anomfutho ophezulu wepompo athinta uketshezi olusagolide olusuka ku-tundish ngesivinini esinqunywe kusengaphambili kanye ne-engeli, aluhlephule lube amaconsi ensimbi. Ngaphansi kwengcindezi yepompo yamanzi efanayo, inani lempushana yensimbi ecolekile ngemva kwe-atomization lihlobene nokusebenza kahle kwe-atomizer ye-atomizer; i-atomization cylinder: indawo lapho i-alloy powder i-atomu, ichotshoziwe, ipholile futhi iqoqwe. Ukuze uvimbele i-ultra-fine alloy powder ku-alloy powder etholiwe ukuthi ingalahleki namanzi, kufanele ishiywe isikhathi esithile ngemva kwe-atomization, bese ifakwa ebhokisini lokuqoqa impushana.

Ingxenye yokucubungula ngemuva:ibhokisi lokuqoqa impushana: lisetshenziselwa ukuqoqa i-athomu ye-alloy powder futhi ihlukanise futhi isuse amanzi amaningi; isithando somlilo: yomisa i-alloy powder emanzi ngamanzi; umshini wokuhlola: hlunga i-alloy powder, Ama-coarser alloy powders angaphandle kokucaciswa angancibilika kabusha futhi enze i-athomu njengempahla yokubuyisela.

Ithrendi Yokuthuthukiswa Kwezisetshenziswa Ze-Atomization Pulverizing Esikhathini Esizayo

Kusenezingqinamba eziningi ekuqondeni ubuchwepheshe bokuphrinta be-3D kuzo zonke izici zomkhakha wokukhiqiza waseShayina. Uma sibheka isimo sangempela sokuthuthukiswa, kuze kube manje ukuphrinta kwe-3D akukafinyeleli ekuthuthukisweni kwezimboni ezivuthiwe, kusukela kumishini kuya emikhiqizweni kuya ezinsizeni ezisesigabeni "sethoyizi elithuthukisiwe". Nokho, kusukela kuhulumeni kuya kumabhizinisi e-China, amathemba okuthuthukiswa kobuchwepheshe bokunyathelisa be-3D ngokuvamile aqashelwa, futhi uhulumeni kanye nomphakathi ngokuvamile banaka umthelela wesikhathi esizayo we-3D yokunyathelisa yensimbi ye-atomization ye-pulverizing imishini yobuchwepheshe ekukhiqizeni okukhona kwezwe lami, umnotho, namamodeli wokukhiqiza.

Ngokusho kwedatha yocwaningo, okwamanje, isidingo sezwe lami sobuchwepheshe bokuphrinta be-3D asigxiliwe kumishini, kodwa sibonakala ezinhlobonhlobo zezinto ezisetshenziswayo zokuphrinta ze-3D kanye nesidingo sezinsizakalo zokucubungula i-ejensi. Amakhasimende ezimboni angamandla amakhulu ekuthengeni imishini yokuphrinta ye-3D ezweni lami. Imishini abayithengayo isetshenziswa kakhulu kwezokundiza, i-aerospace, imikhiqizo ye-elekthronikhi, ezokuthutha, ukuklama, ukusungula amasiko nezinye izimboni. Njengamanje, umthamo ofakiwe wamaphrinta we-3D emabhizinisini aseShayina cishe u-500, futhi izinga lokukhula lonyaka lingaba ngu-60%. Noma kunjalo, usayizi wemakethe wamanje ungama-yuan ayizigidi eziyi-100 kuphela ngonyaka. Isidingo esingaba khona se-R&D kanye nokukhiqizwa kwezinto zokuphrinta ze-3D sesifinyelele cishe kumayuan ayizigidi eziyizinkulungwane eziyi-1 ngonyaka. Ngokuthandwa nokuthuthuka kobuchwepheshe bemishini, isikali sizokhula ngokushesha. Ngasikhathi sinye, izinsiza zokucubungula eziphathelene nokuphrinta ze-3D zithandwa kakhulu, futhi ama-ejenti amaningi aphrinta i-3D Inkampani yezisetshenziswa ivuthwe kakhulu enqubeni ye-laser sintering kanye nokusetshenziswa kwemishini, futhi ingahlinzeka ngezinsizakalo zokucubungula zangaphandle. Njengoba intengo yesisetshenziswa esisodwa ngokuvamile ingaphezu kwama-yuan ayizigidi ezingu-5, ukwamukelwa kwemakethe akuphakeme, kodwa insizakalo yokucubungula i-ejensi ithandwa kakhulu.

Iningi lezinto ezisetshenziswa emishinini yezwe yami yokuphrinta ye-3D yensimbi yokunyathelisa i-atomization ihlinzekwa ngokuqondile ngabakhiqizi be-prototyping abasheshayo, futhi ukunikezwa okuvela eceleni kwezinto ezijwayelekile akukakaqaliswa, okuholela ezindlekweni zezinto ezibonakalayo eziphakeme kakhulu. Ngesikhathi esifanayo, alukho ucwaningo mayelana nokulungiswa kwempushana okunikezelwe ekunyatheliseni kwe-3D e-China, futhi kunezidingo eziqinile mayelana nokusabalalisa usayizi wezinhlayiyana kanye nokuqukethwe komoya-mpilo. Amanye amayunithi asebenzisa impushana yesifutho evamile esikhundleni salokho, enokungasebenzi okuningi.

Ukuthuthukiswa nokukhiqizwa kwezinto ezisebenza ngezindlela eziningi kuyisihluthulelo sentuthuko yezobuchwepheshe. Ukuxazulula izinkinga zokusebenza nezindleko zezinto zokwakha kuzothuthukisa kangcono ukuthuthukiswa kobuchwepheshe bokwenza ama-prototyping ngokushesha e-China. Njengamanje, izinto eziningi ezisetshenziswa kubuchwepheshe bezwe lami bokuphrinta be-3D bokuphrinta ngokushesha zidinga ukungeniswa zivela phesheya, noma abakhiqizi bemishini batshale amandla amaningi kanye nezimali zokuzithuthukisa, ezibizayo, okuholela ekwenyukeni kwezindleko zokukhiqiza, ngenkathi izinto zasekhaya ezisetshenziswa kulo mshini zinamandla aphansi nokunemba. . Ukwenziwa kwasendaweni kwezinto zokuphrinta ze-3D kubalulekile.

I-Titanium ne-titanium alloy powders noma izimpushana ze-nickel-based superalloy ezisekelwe ku-cobalt ezinokuqukethwe okuphansi kwe-oxygen, usayizi wezinhlayiya ezinhle kanye ne-sphericity ephezulu kuyadingeka. Usayizi wezinhlayiyana ze-powder ngokuyinhloko -500 mesh, okuqukethwe kwe-oxygen kufanele kube ngaphansi kuka-0.1%, futhi usayizi wezinhlayiyana ufana Njengamanje, i-high-end alloy powder kanye nemishini yokukhiqiza isathembele kakhulu ekuthengeni kwamanye amazwe. Emazweni angaphandle, izinto zokusetshenziswa kanye nemishini ngokuvamile kuyahlanganiswa futhi kudayiswe ukuze bathole inzuzo eningi. Uma sithatha njengesibonelo impushana esekelwe ku-nickel, izindleko zezinto ezingavuthiwe zingamayuan angu-200/kg, intengo yemikhiqizo yasekhaya ngokuvamile iwu-300-400 yuan/kg, kanti intengo yempushana ethengwa kwamanye amazwe ivamise ukuba ngaphezu kuka-800 yuan/kg.

Isibonelo, umthelela nokuvumelana nezimo kokwakheka kwempushana, okufakiwe kanye nezakhiwo ezibonakalayo kubuchwepheshe obuhlobene bemishini yokugaya i-3D yensimbi yokunyathelisa i-atomization powder. Ngakho-ke, ngenxa yezidingo zokusetshenziswa kokuqukethwe komoyampilo ophansi kanye nosayizi wezinhlayiyana ezincane eziyimpushana, kusadingeka ukwenza umsebenzi wocwaningo njengokwakheka kwe-titanium ne-titanium alloy powder, ubuchwepheshe bokugaya i-atomization powder ye-particle size powder powder, kanye umthelela wezimpawu zempushana ekusebenzeni komkhiqizo. Ngenxa yokulinganiselwa kobuchwepheshe bokugaya e-China, kunzima ukulungisa i-powder-grained powder okwamanje, isivuno se-powder siphansi, futhi okuqukethwe kwe-oxygen nokunye ukungcola kuphezulu. Ngesikhathi senqubo yokusetshenziswa, isimo sokuncibilika kwe-powder sijwayele ukungalingani, okuholela ekuquketheni okuphezulu kwe-oxide inclusions kanye nemikhiqizo ye-denser emkhiqizweni. Izinkinga eziyinhloko zezimpushana ze-alloy zasekhaya zisezingeni lomkhiqizo nokuzinza kweqoqo, okuhlanganisa: ① ukuzinza kwezingxenye zempushana (inombolo yokufaka, ukufana kwezingxenye); ② impushana ngokomzimba Ukuzinza kokusebenza (ukusabalalisa usayizi wezinhlayiyana, i-powder morphology, i-fluidity, isilinganiso esixekethile, njll.); ③ inkinga yesivuno (isivuno esincane sempushana engxenyeni yosayizi wezinhlayiyana ezincane), njll.

Isibonisi somkhiqizo

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur