Isisetshenziswa Esiqhubekayo Sokusakaza Se-Hasung-High Vacuum Yezinsimbi Eziyigugu

1, Incazelo Yezisetshenziswa:

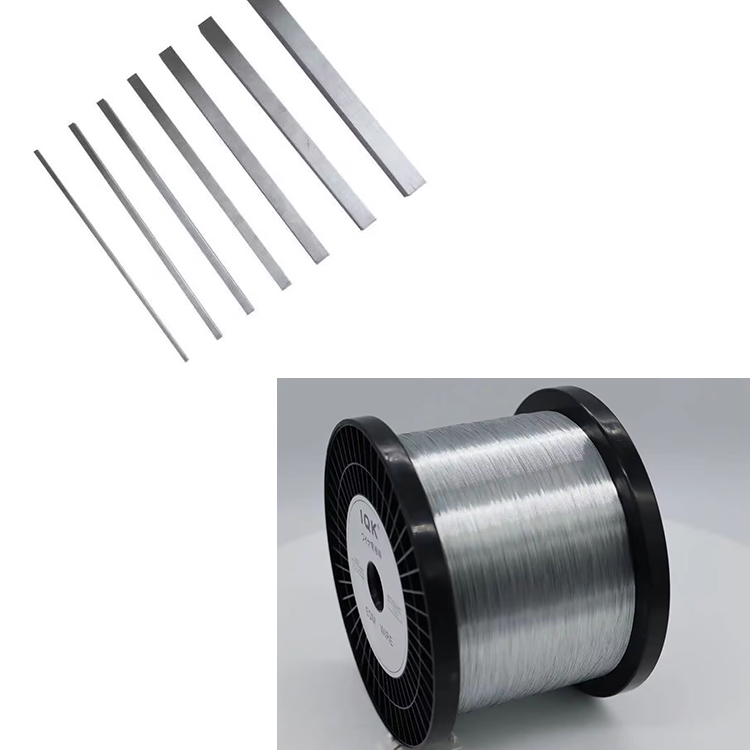

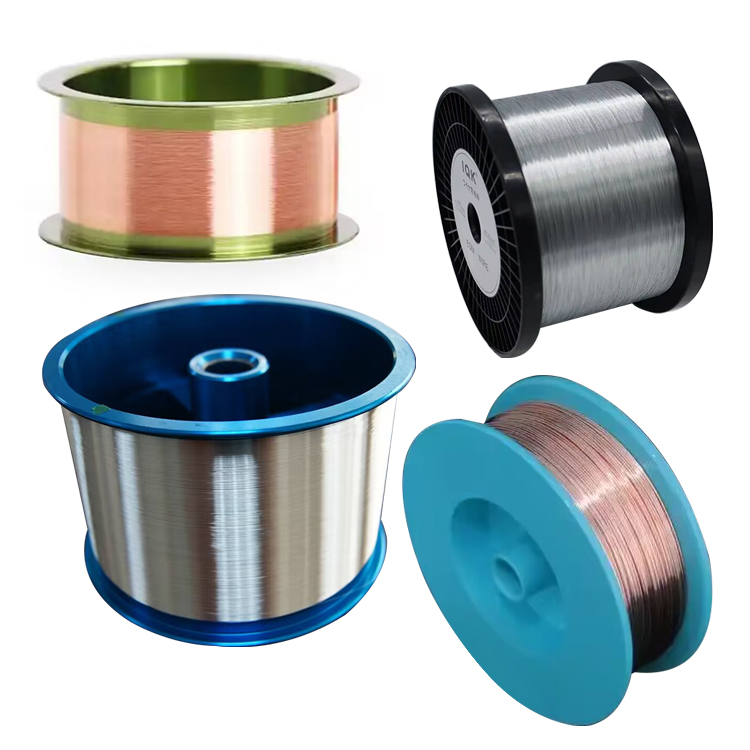

1. Le mishini isetshenziselwa ikakhulukazi ukusakazwa okuqhubekayo kwezinsimbi zethusi zekristalu eyodwa, imigoqo yesiliva yekristalu eyodwa, nezinsimbi zegolide zekristalu eyodwa, futhi ingasetshenziselwa ukukhiqiza okuqhubekayo kwezinye izinsimbi nama-alloys.

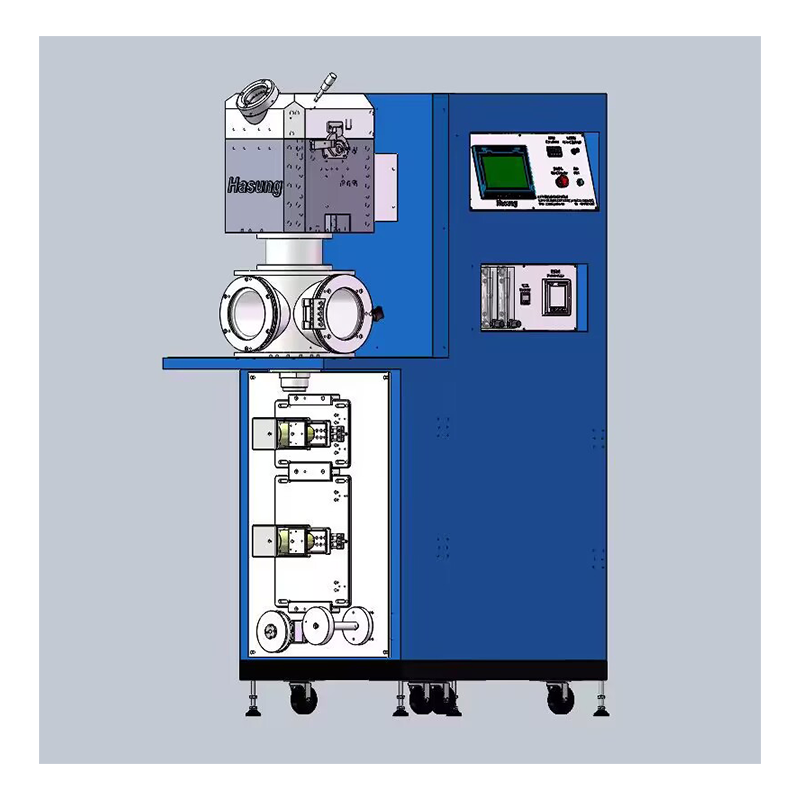

2. Le mishini ingumzimba wesithando somlilo omile. Izinto zokusetshenziswa, i-crucible, ne-crystallizer zifakwa kukhava yesithando somlilo esivulwe phezulu, futhi induku yomhlahlandlela we-crystallization ifakwa engxenyeni engezansi yomzimba wesithando somlilo. Okokuqala, i-crystal ikhishwa ekuncibilikeni ngobude obuthile ngokusebenzisa induku yomhlahlandlela we-crystallization, bese i-crystal rod igxiliwe emshinini wokugoqa ukuze udwebe futhi uqoqwe.

3. Le divayisi yamukela isikrini sokuthinta ngokugcwele uhlelo lokulawula okuzenzakalelayo olunamadivayisi amaningi okuqapha ukulawula ngokunembile izinga lokushisa lesithando somlilo kanye ne-crystallizer, ukufeza izimo ezinzile zesikhathi eside ezidingekayo ekukhuleni kwekristalu; Izenzo eziningi zokuzivikela zingenziwa ngokusebenzisa imishini yokuqapha, njengokuvuza kwezinto ezibangelwa ukushisa kwesithando somlilo, i-vacuum enganele, amanzi ngaphansi kwengcindezi noma ukushoda, njll. Imishini kulula ukuyisebenzisa, futhi imingcele eyinhloko emisiwe ihlanganisa ukushisa kwesithando somlilo, izinga lokushisa izingxenye ezingenhla, eziphakathi, neziphansi ze-crystallizer, isivinini sangaphambi kokudonsa, isivinini sokudonsa sekristalu (kanye nemodi eyi-inch, okusho ukudonsa isikhathi esithile nokuma isikhathi esithile. isikhathi), kanye namanani e-alamu ahlukahlukene.

Umshini Wokusakaza Oqhubekayo We-Hasung Eyigugu Ngokugcwele Okuzenzakalelayo

2, Imingcele yezobuchwepheshe eyinhloko yemishini:

1. Uhlobo: Ukulawula okuqondile, okuzenzakalelayo, ukushisa okuzenzakalelayo.

2. Isamba samandla kagesi: isigaba sesithathu esingu-380V, 50Hz isigaba sesithathu

3. Amandla okushisa: 20KW

4. Indlela yokushisisa: Ukushisa kokungenisa (okungenamsindo)

5. Umthamo: 8kg (igolide)

6. Isikhathi sokuncibilika: 3-6 imizuzu

7. Izinga lokushisa eliphezulu: 1600 degrees Celsius

6. Ububanzi benduku yethusi: 6-10m

7. I-vacuum degree: Isimo esibandayo<6 67× 10-3Pa

8. Izinga lokushisa: 1600 ℃

9. Isivinini sokudonsa induku yethusi: 100-1500mm/min (iyalungiseka)

10. Izinsimbi ezisansimbi: igolide, isiliva, ithusi, nezinto zengxubevange.

11. Indlela yokupholisa: Ukupholisa amanzi (ukushisa kwamanzi 18-26 degrees Celsius)

12. Imodi yokulawula: I-Siemens PLC+ukulawula okuhlakaniphile kwesikrini sokuthinta

13. Usayizi wezinto: 2100 * 1280 * 1950mm

14. Isisindo: Cishe i-1500kg. Vacuum ephezulu: cishe 550kg.

3. Incazelo yesakhiwo eyinhloko:

1. Umzimba wesithando somlilo: Umzimba wesithando somlilo wamukela uhlaka olume mpo olunezingqimba ezimbili zokupholisa amanzi. Isembozo sesithando somlilo singavulwa ukuze kufakwe kalula ama-crucibles, amakristalu, nezinto zokusetshenziswa. Kukhona iwindi lokubuka engxenyeni engenhla yesembozo sesithando somlilo, elikwazi ukubona isimo sezinto ezincibilikisiwe ngesikhathi sokuncibilika. Ama-electrode okungenisa ama-flange kanye nama-flange epayipi le-vacuum ahlelwa ngokulinganayo ezindaweni ezihlukene zokuphakama phakathi nomzimba wesithando somlilo ukuze ethule amalunga e-electrode yokungeniswa futhi axhumane neyunithi ye-vacuum. Ipuleti elingaphansi kwesithando somlilo lifakwe uhlaka losekelo lwe-crucible, eliphinde lisebenze njengenqwaba engaguquki ukuze kulungiswe ngokunembile indawo yecrystallizer, iqinisekisa ukuthi imbobo emaphakathi yecrystallizer igxile esiteshini sokuvala epuleti elingaphansi kwesithando somlilo. Uma kungenjalo, induku yomhlahlandlela we-crystallization ngeke ikwazi ukungena ngaphakathi kwe-crystallizer ngokusebenzisa isiteshi sokuvala. Kunamasongo amathathu apholise amanzi kuhlaka lokusekela, ahambisana nezingxenye ezingaphezulu, ezimaphakathi, nezingezansi zekristalu. Izinga lokushisa lengxenye ngayinye ye-crystallizer lilawulwa ngokunembile ngokulawula izinga lokugeleza kwamanzi okupholisa. Kunama-thermocouples amane kuhlaka lokusekela, asetshenziselwa ukukala izinga lokushisa lezingxenye ezingenhla, ezimaphakathi, neziphansi ze-crucible ne-crystallizer, ngokulandelana. Isixhumi esibonakalayo phakathi kwama-thermocouples nangaphandle kwesithando sitholakala epuleti elingaphansi kwesithando somlilo. Isitsha sokukhipha amanzi singabekwa ngaphansi kohlaka lokusekela ukuvimbela izinga lokushisa lokuncibilika ukuthi lingagelezi lisuka phansi lisuka kumshini wokuhlanza bese lidala umonakalo emzimbeni wesithando somlilo. Kukhona futhi negumbi elincane elimahhadla elikhiphekayo endaweni emaphakathi epuleti elingaphansi lesithando somlilo. Ngezansi kwegumbi le-vacuum elimahhadla kunegumbi lengilazi lemvelo elingangezwa nge-anti-oxidation ukuze kuthuthukiswe ukuvala kwe-vacuum kocingo olucolekile. Impahla ingafinyelela umphumela we-anti oxidation ebusweni benduku yethusi ngokwengeza i-ejenti ephikisana ne-oxidation emgodini wengilazi wemvelo.

2. I-Crucible kanye ne-Crystallizer: I-crucible ne-crystallizer yenziwe nge-high-purity graphite. Iphansi le-crucible liyi-conical futhi lixhunywe ku-crystallizer ngokusebenzisa imicu.

3. Isistimu ye-vacuum:

1. Iphampu yezimpande

2. I-valve ye-pneumatic high vacuum disc

3. Electromagnetic high vacuum vacuum inflation valve

4. Igeji ye-vacuum ephezulu

5. Igeji yevacuum ephansi

6. Umzimba wesithando somlilo

7. I-vacuum baffle valve ephezulu ye-pneumatic

8. Ugibe olubandayo

9. Iphampu yokusabalalisa

4. Indlela yokudweba nokusonta: Ukusakazwa okuqhubekayo kwamabha ethusi kuhlanganisa amasondo omhlahlandlela, izinduku zezikulufu ezinembayo, iziqondiso ezilandelanayo, nezindlela zokusonta. Isondo eliqondisayo lidlala indima yokuqondisa nokubeka indawo, futhi into yokuqala induku yethusi edlula kuyo lapho iphuma esithandweni somlilo isondo lokuqondisa. I-crystallization guide rod igxilile kusikulufa sokunemba kanye nedivayisi yomhlahlandlela womugqa. Induku yethusi iqala ikhishwe emzimbeni wesithando somlilo (idonswe ngaphambili) ngokunyakaza okulandelanayo kwenduku yomhlahlandlela wecrystallization. Lapho induku yethusi idlula esondweni lomhlahlandlela futhi inobude obuthile, ukuxhumana nenduku ye-crystallization guide kunganqanyulwa. Khona-ke igxiliwe emshinini wokusonga futhi iqhubeke nokudweba induku yethusi ngokujikeleza komshini wokusonga. I-servo motor ilawula ukunyakaza komugqa kanye nokujikeleza komshini osongayo, ongalawula ngokunembile isivinini sokusakaza esiqhubekayo senduku yethusi.

5. I-ultrasonic power supply yesistimu yamandla isebenzisa i-IGBT yesiJalimane, enomsindo ophansi nokonga amandla. Umthombo usebenzisa amathuluzi okulawula izinga lokushisa ukufudumeza okuhleliwe. Idizayini yesistimu kagesi

Kukhona i-overcurrent, impendulo ye-overvoltage namasekhethi okuvikela.

6. Uhlelo lokulawula: Le mishini yamukela isikrini sokuthinta ngokugcwele uhlelo lokulawula okuzenzakalelayo olunamadivayisi amaningi okuqapha ukulawula ngokunembile izinga lokushisa lesithando somlilo kanye ne-crystallizer, ukufeza izimo ezinzile zesikhathi eside ezidingekayo ukuze kuqhutshwe induku yethusi ngokuqhubekayo; Izenzo eziningi zokuzivikela zingenziwa ngokusebenzisa imishini yokuqapha, njengokuvuza kwezinto ezibangelwa ukushisa kwesithando somlilo, i-vacuum enganele, amanzi ngaphansi kwengcindezi noma ukushoda, njll. Imishini kulula ukuyisebenzisa futhi imingcele eyinhloko isethiwe.

Kukhona izinga lokushisa lomlilo, izinga lokushisa lezingxenye ezingaphezulu, ezimaphakathi, neziphansi zekristalu, isivinini sangaphambi kokudonsa, kanye nesivinini sokudonsa sekristalu.

Namanani e-alamu ahlukahlukene. Ngemva kokubeka imingcele ehlukahlukene, ekukhiqizeni induku yethusi okuqhubekayo, inqobo nje uma ukuphepha kuqinisekiswa.

Beka induku yomhlahlandlela we-crystallization, beka izinto zokusetshenziswa, vala umnyango wesithando somlilo, unqamule ukuxhumana phakathi kwenduku yethusi kanye nenduku yomhlahlandlela we-crystallization, bese uyixhuma emshinini wokuvala.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur