I-Hasung T2 Jewelry Vacuum Pressure Casting Machine

Kungani Ukhetha Umshini Wokusakaza we-Hasung Vacuum Pressure?

I-Hasung T2 Vacuum Casting Machines iqhathaniswa nezinye izinkampani

1. Ukusebenza kokusakaza okunembile

2. Isivinini esihle sokuncibilika. Isivinini sokuncibilika singaphakathi kwamaminithi angu-2-3.

3. Ukucindezela okunamandla kokuphonsa.

4. Izingxenye zoqobo zikaHasung ziyimikhiqizo eyaziwayo evela ezindlini, eJapan naseGermanu.

5. Ukusebenza kokusakaza okunembile

6. Sekela izinkumbulo zohlelo eziyi-100

7. Ukonga amandla. Ngokusetshenziswa kwamandla aphansi 10KW 380V 3 isigaba.

8. Ukusebenzisa i-nitrogen noma i-argon kuphela, asikho isidingo sokuxhuma emoyeni we-compressor.

Imingcele Yezobuchwepheshe

| Imodeli No. | I-HS-T2 |

| Amandla kagesi | 380V, 50/60Hz, 3 izigaba |

| Ukunikezwa kwamandla kagesi | 10KW |

| I-Max Temp | 1500°C |

| Isikhathi Sokuncibilika | 2-3 amaminithi. |

| Igesi Lokuvikela | I-Argon / i-nitrogen |

| Ukunemba Kwesikhashana | ±1°C |

| Amandla (Igolide) | 24K: 2.0Kg, 18K: 1.55Kg, 14K: 1.5Kg, 925Ag: 1.0Kg |

| I-Crucible Volume | 242CC |

| Usayizi weflask omkhulu | 5"x12" |

| Iphampu yeVacuum | Iphampu ye-vacuum yekhwalithi ephezulu |

| Isicelo | Igolide, i-K igolide, isiliva, ithusi namanye ama-alloys |

| Indlela yokusebenza | Ukhiye owodwa uqeda yonke inqubo yokusakaza |

| Uhlobo lokupholisa | I-water chiller (ithengiswa ngokwehlukana) noma Amanzi agijimayo |

| Ubukhulu | 800*600*1200mm |

| Isisindo | cishe. 230kg |

Isibonisi somkhiqizo

Isihloko: I-Evolution of Gold Jewelry Casting Technology: From Ancient Techniques to Ancient Innovations

Sekungamakhulu eminyaka ubucwebe begolide buwuphawu lomcebo, isimo nobuhle. Kusukela empucukweni yasendulo kuya emfashinini yesimanje, ubuhle begolide buhlala bufana. Enye yezinqubo ezibalulekile ekudaleni ubucwebe begolide ukuphonsa, okuguquke kakhulu ngokuhamba kwesikhathi. Kule bhulogi, sizohlola uhambo oluhehayo lobuchwepheshe bokulingisa ubucwebe begolide, kusukela ekuthuthukisweni kwayo kwasekuqaleni kuya emasuni aphambili anamuhla.

Ubuchwepheshe Basendulo: Ukuzalwa Kokusakaza Kwegolide

Umlando wokubunjwa kwegolide ungalandelelwa emuva empucukweni yasendulo efana neGibhithe, iMesophothamiya, neChina. Lezi zingcweti zakuqala zakha izindlela eziyisisekelo zokubumba zisebenzisa isikhunta esilula esenziwe ngobumba, isihlabathi, noma itshe. Le nqubo ihilela ukushisisa igolide lize lifinyelele esimweni esincibilikisiwe bese lithela ezibunjeni ezilungisiwe ukuze kwakhiwe ubucwebe.

Nakuba lezi zindlela zasendulo zaziyisisekelo ngesikhathi sazo, zazilinganiselwe ngokunemba nokuba yinkimbinkimbi. Ubucwebe obuvelayo ngokuvamile bubonakala bumahhadlahhadla futhi buluhlaza, buntula imininingwane emihle nemiklamo eyinkimbinkimbi ebonisa ubucwebe begolide besimanje.

Inqubekelaphambili Yenkathi Ephakathi: Ukunyuka Kokusakaza Kwengcina Okulahlekile

Phakathi neNkathi Ephakathi, intuthuko enkulu kubuchwepheshe bokuphonswa kwegolide kwenzeka ngokuthuthukiswa kobuchwepheshe bokukhipha i-wax obulahlekile. Le ndlela yashintsha inqubo yokulingisa, ivumela izingcweti ukuthi zenze izingcezu zobucwebe eziyinkimbinkimbi futhi ezinemininingwane.

Inqubo yokukhipha i-wax elahlekile ihilela ukudala imodeli ye-wax ye-design jewelry efunwayo, ebuye ihlanganiswe esikhunjeni esenziwe nge-plaster noma ubumba. Isikhunta siyashisisa, senze ukuthi ingcina incibilike futhi ihwamuke, ishiye imbobo esesimweni semodeli yengcina yokuqala. Igolide elincibilikisiwe lalibe selithelwa emgodini, okwenza umfanekiso onembile nonemininingwane wemodeli ye-wax.

Lobu buchwepheshe buphawule igxathu elikhulu eliya phambili ocingweni lokulingisa igolide, okuvumela izingcweti ukuthi zikhiqize ubucwebe obunamaphethini ayinkimbinkimbi, umsebenzi we-filigree obucayi, kanye nokwenziwa kahle obekungenakufezwa ngaphambilini.

Inguquko Yezimboni: Inqubo Yokusakaza Emshinini

I-Industrial Revolution yaletha igagasi lokuthuthuka kwezobuchwepheshe elaguqula izinqubo zokukhiqiza ezimbonini ezihlukahlukene, kuhlanganise nokukhiqizwa kobucwebe. Ngalesi sikhathi, izinqubo zokulingisa ngemishini zethulwa, okuvumela ukukhiqizwa ngobuningi kobucwebe begolide.

Enye yezinto ezintsha ezibalulekile kwaba ukuthuthukiswa komshini wokuphonsa we-centrifugal, owasebenzisa amandla e-centrifugal ukusabalalisa ngokulinganayo igolide elincibilikisiwe esikhunjeni. Le nqubo ezenzakalelayo inyusa kakhulu ukusebenza kahle nokuvumelana kokusakazwa kwegolide, okuholela ekukhiqizweni okuphezulu kanye nezingcezu zobucwebe ezisezingeni eliphakeme.

Ukuqamba okusha kwesimanje: ukwakheka kwedijithali nokuphrinta kwe-3D

Emashumini eminyaka amuva nje, ukuvela kwedizayini yedijithali kanye nobuchwepheshe bokuphrinta be-3D kuguqule isimo sokusakazwa kobucwebe begolide. Lezi zindlela ezintsha ezisezingeni eliphezulu ziye zashintsha indlela imiklamo yobucwebe edalwa ngayo futhi yahunyushwa ezintweni ezibonakalayo.

Isoftware yedizayini yedijithali inika amandla abaklami bobucwebe ukuthi bakhe amamodeli e-3D ayinkimbinkimbi ngokunemba okungakaze kubonwe kanye nemininingwane. Lawa mamodeli edijithali angabe eseguqulwa abe ama-prototypes angokoqobo kusetshenziswa ubuchwepheshe bokuphrinta be-3D, obakha ungqimba lobucwebe ngongqimba kusetshenziswa izinto ezahlukahlukene, kufaka phakathi i-wax yokusakazwa.

Ukusetshenziswa kokuphrinta kwe-3D ekufakweni kobucwebe begolide kuvula amathuba amasha okudala amadizayini ayinkimbinkimbi kakhulu futhi enziwe ngokwezifiso abengafinyeleleki ngaphambilini ngokusebenzisa izindlela zokulingisa zendabuko. Ubuchwepheshe buphinde buhlelembe inqubo yokwenza i-prototyping kanye nokukhiqiza, ukunciphisa izikhathi zokuhola futhi buvumele ukuphindaphindeka okusheshayo kwemiklamo yobucwebe.

Ukwengeza, ukuthuthuka kobuchwepheshe be-metallurgical kanye ne-alloying kusize ukuthuthukiswa kwama-alloys egolide amasha anezakhiwo ezithuthukisiwe ezifana namandla akhulayo, ukuqina, nokushintsha kombala. Lezi zingxubevange ezintsha zandisa amathuba okudala abaklami nabakhiqizi bobucwebe, okubavumela ukuthi basunduze imingcele yobucwebe begolide bendabuko.

Ikusasa lobucwebe begolide ekubunjweni ubuchwepheshe

Njengoba ubuchwepheshe buqhubeka buthuthuka, ikusasa lokulingisa ubucwebe begolide liphethe amathuba ajabulisayo nakakhulu. Ubuchwepheshe obusafufusa njengokukhiqiza okungeziwe kanye namarobhothi athuthukile kulindeleke ukuthi kuqhubeke ukuguqula inqubo yokulingisa, ilethe amazinga amasha okunemba, ukusebenza kahle kanye nokwenza ngokwezifiso.

Ukwengeza, ukuhlanganisa ubuhlakani bokwenziwa kanye nama-algorithms okufunda komshini ekwakhiweni kobucwebe kanye nokugeleza komsebenzi wokukhiqiza kunamandla okuthuthukisa inqubo yokuphonsa, ukunciphisa udoti wezinto ezibonakalayo, nokuthuthukisa ikhwalithi iyonke yobucwebe obuqediwe.

Sengiphetha, ukuvela kobuchwepheshe bokuphonsa ubucwebe begolide kuwubufakazi bobuhlakani nokwenziwa okusha kwezingcweti nochwepheshe kuwo wonke umlando. Kusukela kumasu asendulo okulahleka kwe-wax kuya kuzimangaliso zesimanje zedizayini yedijithali nokuphrinta kwe-3D, ubuciko bokubunjwa kwegolide buyaqhubeka nokuguquguquka ukuze buhlangabezane nezidingo zezikhathi ezishintsha njalo.

Uma sibheka ikusasa, kuyacaca ukuthi ukuhlanganiswa kobuciko bendabuko kanye nobuchwepheshe obusezingeni eliphezulu kuzoqhubeka nokubumba indawo yokukhishwa kobucwebe begolide, kunikeze amathuba angapheli okudala, ukwenza ngokwezifiso kanye nekhwalithi emhlabeni wobucwebe obuhle.

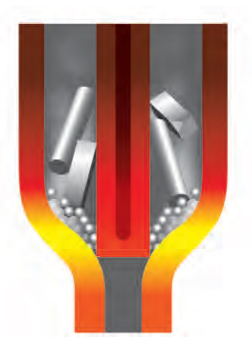

Izinto ezisetshenziswayo zomshini wokukhipha umfutho we-vacuum:

1. I-graphite crucible

2. I-Ceramic gasket

3. Ijazi le-Ceramic

4. Isivalo se-graphite

5. Thermocouple

6. Ikhoyili yokushisa

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur