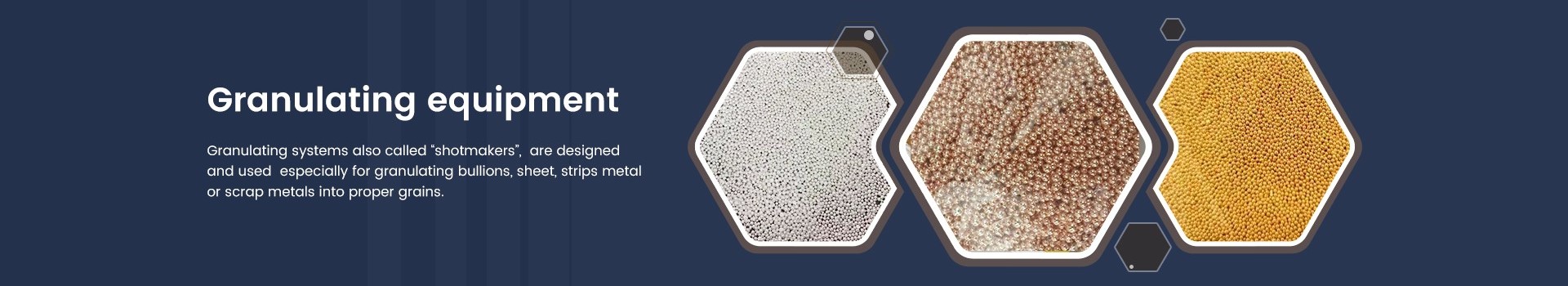

Granulating Systems

Amasistimu okugaya abuye abizwe ngokuthi “abadubuli”, aklanywa futhi asetshenziselwa ikakhulukazi izimbumbulu zezinhlamvu, amashidi, amapheshana ensimbi noma izinsimbi ezilahliwe zibe izinhlamvu ezifanele. Amathangi e-granulating kulula kakhulu ukuwasusa ukuze asuswe. Isibambo sokudonsa ukuze kukhishwe kalula okokufaka ithangi. Izinto ozikhethela zona zomshini wokukhipha umfutho we-vacuum noma umshini wokuphonsa oqhubekayo onethangi le-granulating iyisixazululo sokuhlanganisa ngezikhathi ezithile futhi. Amathangi e-granulating ayatholakala kuyo yonke imishini ochungechungeni lwe-VPC. Uhlobo olujwayelekile lwe-granulating systems lufakwe ithangi elinamasondo amane ahamba kalula ngaphandle nangaphakathi.

-

Metal Granulator Machine for Gold Silver Copper 4kg 6kg 8kg10kg15kg

1. Ngokulawulwa kwezinga lokushisa, ukunemba kufika ku-±1°C.

2. Idizayini ye-Ultra-human, ukusebenza kulula kunezinye.

3. Sebenzisa isilawuli seMitsubishi esingenisiwe.

4. I-Silver Granulator ene-temperature control (I-Gold Silver Granu Casting Machine, Umshini Wokuhlanganisa Wesiliva).

5. Lo mshini wamukela ubuchwepheshe bokushisisa obuthuthukisiwe be-IGBT, umphumela wokuphonsa muhle kakhulu, uhlelo luzinzile futhi luphephile, umthamo wegolide elincibilikisiwe uyazikhethela, futhi ukucaciswa kwensimbi eyi-granulated kuyakhethwa.

6. Ijubane le-granulation liyashesha futhi alinawo umsindo. Imisebenzi ephelele yokuhlola nokuvikela ethuthukisiwe yenza wonke umshini uphephe futhi uhlale isikhathi eside.

7. Umshini unomklamo wokuhlukanisa futhi umzimba unendawo yamahhala.

-

I-Platinum Granulating Machine Granulating 10kg

I-Hasung Platinum Shot Maker Granulating Machine uma iqhathaniswa nemikhiqizo efanayo emakethe, inezinzuzo ezivelele ezingenakuqhathaniswa ngokusebenza, ikhwalithi, ukubukeka, njll., futhi ijabulela idumela elihle emakethe.I-Hasung ifingqa iziphambeko zemikhiqizo edlule, futhi ngokuqhubekayo kuyabathuthukisa. Imininingwane ye-Hasung Platinum Shot Maker Granulating Machine ingenziwa ngezifiso ngokwezidingo zakho.

Izinzuzo eziyinhloko zezizukulwane ezintsha zabathwebuli bezithombe

Ukufakwa kalula kwethangi le-granulating elinepulatifomu

Ukusebenza kwe-granulating yekhwalithi ephezulu

Idizayini ye-ergonomically nelinganiselwe ngokuphelele yokuphatha okuphephile nokulula

Ukuziphatha kokusakaza-bukhoma okulungiselelwe kwamanzi okupholisa

Ukuhlukaniswa okuthembekile kwamanzi nama-granules -

I-Vacuum Shot Maker ye-Gold Silver Copper 4kg 8kg 10kg

Idizayini yalolu hlelo lwe-vacuum granulator isekelwe ezidingweni zangempela zenqubo yensimbi eyigugu ngokusebenzisa ubuchwepheshe besimanje bokushisa obusezingeni eliphezulu.

I-vacuum granulator isetshenziselwa ukukhiqiza okusanhlamvu okuphezulu kwekhwalithi ephezulu kanye ne-homogenous yezinsimbi eziyigugu njengegolide, isiliva, ithusi, nama-alloys, kusukela ezintweni ezingavuthiwe ezincibilikisiwe ukushisisa okungeniswa kwe-Hasung endaweni evikela igesi engasebenzi, bese yehlelwa ethangini lamanzi lidlula. ngokusebenzisa i-multi-hollow crucible esebenza njenge-flow breaker.

I-vacuum granulator isebenzisa i-vacuum ngokugcwele kanye nokuncibilika kwegesi ye-inert kanye ne-granulating, umshini unganyakaza ngokuzenzakalelayo ekuncibilikeni, ukugqugquzela u-electromagnetic, kanye nesiqandisi ekamelweni elincibilikisayo lokuvikela igesi elivaliwe + le-inert, ukuze umkhiqizo ube nezici zokungabi ne-oxidation, super. ukulahlekelwa okuphansi, akukho zimbotshana, akukho ukuhlukaniswa ngombala, nokubukeka okuhle nobukhulu obufanayo.

Le mishini isebenzisa uhlelo lokulawula uhlelo lwe-Mitsubishi PLC, i-SMC pneumatic kanye ne-Panasonic servo motor drive kanye nezinye izingxenye zomkhiqizo ezaziwayo ekhaya naphesheya.

-

I-High Vacuum Granulating System ye-Gold Silver Copper 20kg 50kg 100kg

I-vacuum granulator ephezulu igoqa izinhlayiya zensimbi eziyigugu zokuphonswa kwentambo yokubopha: igolide, isiliva nethusi, intambo yokubopha isetshenziselwa ikakhulukazi izinto zokwakha ze-semiconductor, izinto zokushisela i-photovoltaic, izinto zezokwelapha, imishini yobuhlakani bokwenziwa.Futhi laba bathwebuli bensimbi be-vacuum ephezulu bathuthukiswa ikakhulukazi amabhiliyoni e-granulating. , ishidi lensimbi, noma izinsalela zibe izinhlamvu ezifanele. Amathangi e-granulating kulula kakhulu ukuwasusa ukuze ahlanzwe. I-HS-VGR High Vacuum Granulating Machines iyatholakala ngomthamo wokugoqa kusuka ku-20kg kuya ku-100kg. Izinto ezisetshenziswayo zomzimba zisebenzisa insimbi engagqwali engu-304 eqinisekisa ikhwalithi yokuphila isikhathi eside isetshenziswa, futhi nedizayini eyimojula yokugcwalisa ikhwalithi edingekayo.

Izinhlelo zokusebenza ezinkulu:

1. Ukulungiswa kwama-alloys ngegolide ne-master alloy

2. Ukulungiswa kwezingxenye ze-alloy

3. Ukulungiswa kwama-alloys kusuka ezingxenyeni

4. Ukuhlanzwa kwensimbi eseyakhiwe kakade

5. Ukwenza okusanhlamvu kwensimbi kumadili ensimbi ayiguguUchungechunge lwe-VGR lwenzelwa ukukhiqizwa kwezinhlamvu zensimbi ezinosayizi wokusanhlamvu ophakathi kuka-1.5 mm no-4mm. Amasistimu asekelwe kumayunithi e-Hasung granulation, kodwa zonke izingxenye ezibalulekile, ikakhulukazi isistimu yejethi, ziyintuthuko ekhethekile.

Umthamo omkhulu njengesistimu ye-vacuum granulating engu-100kg uyazikhethela ukuthi ifakwe nohlelo lokulawula lwe-Mitsubishi PLC Touch Panel ngayinye.

Imishini ekhethwayo yokucindezela kwe-vacuum noma umshini wokuphonsa oqhubekayo onethangi le-granulating yisisombululo esifanelekile se-granulating ngezikhathi ezithile. Amathangi e-granulating ayatholakala kuyo yonke imishini yochungechunge lwe-VC.

Izinzuzo eziyinhloko zezizukulwane ezintsha zabathwebuli bezithombe:

1. Ukufakwa kalula kwe-tank granulating

2. Ukushintsha ngokushesha phakathi kwenqubo yokuphonsa kanye ne-granulating

3. Idizayini ye-ergonomically futhi elinganiselayo ngokuphelele yokuphatha okuphephile nokulula

4. Ukusakaza okuthuthukisiwe kokuziphatha kwamanzi okupholisa

5. Ukuhlukaniswa okuthembekile kwamanzi nama-granules

6. Okunamandla kakhulu futhi kusebenza kahle emaqenjini okucwenga izinsimbi eziyigugu.

7. Ukonga amandla, ukuncibilika ngokushesha. -

Metal Granulating Machine for Gold Silver Copper Alloy 20kg 30kg 50kg 100kg 150kg

1. Ngokulawulwa kwezinga lokushisa, ukunemba kufika ku-±1°C.

2. Idizayini ye-Ultra-human, ukusebenza kulula kunezinye.

3. Sebenzisa isilawuli seMitsubishi esingenisiwe.

4. I-Silver Granulator ene-temperature control (I-Gold Silver Granu Casting Machine, Umshini Wokuhlanganisa Wesiliva).

5. Lo mshini wamukela ubuchwepheshe bokushisisa obuthuthukisiwe be-IGBT, umphumela wokuphonsa muhle kakhulu, uhlelo luzinzile futhi luphephile, umthamo wegolide elincibilikisiwe uyazikhethela, futhi ukucaciswa kwensimbi eyi-granulated kuyakhethwa.

6. Ijubane le-granulation liyashesha futhi alinawo umsindo. Imisebenzi ephelele yokuhlola nokuvikela ethuthukisiwe yenza wonke umshini uphephe futhi uhlale isikhathi eside.

7. Umshini unomklamo wokuhlukanisa futhi umzimba unendawo yamahhala.

-

Usayizi ohlangene weMetal Granulator Isisetshenziswa Sokuhlanganisa Igolide Lesiliva

Izidubuli zensimbi ezinosayizi omncane. Ngokulawula izinga lokushisa, ukunemba kufika ku-±1°C.

Idizayini yobuntu obukhulu, ukusebenza kulula kunezinye.

Sebenzisa isilawuli se-Mitsubishi esingenisiwe.Lo mshini wamukela ubuchwepheshe bokushisa obuthuthukisiwe be-IGBT baseJalimane, umphumela wokulingisa muhle kakhulu, isistimu izinzile futhi iphephile, umthamo wegolide elincibilikisiwe uyazikhethela, kanye nokucaciswa kwensimbi eyi-granulated kuyakhethwa. Isivinini se-granulation siyashesha futhi akukho msindo. Imisebenzi ephelele yokuhlola nokuvikela ethuthukisiwe yenza wonke umshini uphephe futhi uhlale isikhathi eside. Umshini unomklamo ohlukanisiwe futhi umzimba unendawo yamahhala.

Kusetshenziswa ngaphandle kwe-compressor yomoya, ukusakaza ngesivalo sokuvula esisebenza ngomshini.

Le GS Series granulating system ilungele umthamo omncane ukusuka ku-1kg kuya ku-8kg umthamo (igolide), ilungele amakhasimende anendawo encane.

Iyini imbudumbudu yensimbi?

Imbudumbudu (kusuka kusiLatini: igranum = “okusanhlamvu”) kuyindlela yomkhandi wegolide lapho ingaphezulu letshe eliyigugu lihlotshiswa ngezimbulunga ezincane zensimbi eyigugu, okuthiwa ama-granules, ngokuya ngephethini yokuklama. Ukutholwa kwezinto zakudala zakudala zamatshe ayigugu enziwe ngale ndlela kwatholakala emathuneni asebukhosini base-Uri, eMesopotamiya futhi kubuyela emuva ku-2500 BC Ukusuka kule ndawo, le nqubo yasakazekela e-Anatolia, eSiriya, eTroy (2100 BC) futhi ekugcineni e-Etruria. (ngekhulu lesi-8 BC). Kwaba ukushabalala kancane kancane kwesiko lama-Etruria phakathi kwekhulu lesithathu nelesibili BC okwabangela ukwehla kwegranulation.1 AmaGreki asendulo ayesebenzisa umsebenzi wokuhlanganisa, kodwa yizingcweti zase-Etruria ezaduma ngale ndlela ngenxa ukuthunyelwa kwabo okungaqondakali kwe-powder granulation2 ngaphandle kokusetshenziswa okubonakalayo kwe-solder eqinile.

I-granulation cishe iyona engaqondakali kakhulu futhi ethakazelisayo yamasu okuhlobisa asendulo. Ethulwa izingcweti uFenici noGreci e-Etruria ngekhulu lesi-8 BC, lapho ulwazi lwensimbi nokusetshenziswa kwezinsimbi eziyigugu kwase kusezingeni eliphezulu, uchwepheshe wabakhandi begolide base-Etruscan benza le nqubo yaba eyabo ukuze benze imisebenzi yobuciko eyinkimbinkimbi nobuhle obungenakulinganiswa.

Phakathi nengxenye yokuqala yeminyaka yawo-1800 ukumba okuningana kwenziwa endaweni yase-Rome (i-Cerveteri, i-Toscanella ne-Vulci) kanye ne-Southern Russia (i-Kertch ne-Taman peninsulas) okwaveza ubucwebe basendulo base-Etruscan kanye nesiGreki. Lawa matshe ayigugu ayehlotshiswe nge-granulation. Ubucwebe bafika ekunakekeleni koMndeni wakwaCastellani wabahlobisi ababehileleke kakhulu ocwaningweni lwasendulo lobucwebe. Okutholwe ezindaweni zokungcwaba zase-Etruscan kudonse ukunakwa okukhulu ngenxa yokusebenzisa kwawo ama-granules amahle kakhulu. U-Alessandro Castellani wafunda lawa ma-artifact ngokuningiliziwe ukuze azame ukwembula indlela yawo yokwenza. Kwaze kwaba ngasekuqaleni kwekhulu lama-20, ngemva kokufa kukaCastellani, lapho indida ye-colloidal/eutectic soldering yagcina ixazululiwe.

Nakuba imfihlo yahlala iyimpicabadala kwabakwaCastellanis nakubantu besikhathi sabo, ubucwebe base-Etruscan obusanda kutholwa babangela imvuselelo yobucwebe bemivubukulo cishe ngawo-1850. Kwatholakala izindlela zokwenziwa kwegolide ezavumela u-Castellani nabanye ukuba bakhiqize kabusha ngokwethembeka obunye ubucwebe basendulo obuhle kakhulu obake bambiwa. Eziningi zalezi zindlela zazihluke kakhulu kulezo ezaziqashwe ama-Etruscans nokho zazisenemiphumela ephumelelayo. Iningi lalezi zinto zobucwebe be-Archaeological Revival manje seliqoqweni elibalulekile lobucwebe emhlabeni wonke, kanye nozakwabo basendulo.

IZITHOMBE

Ama-granules enziwe nge-alloy efanayo nensimbi azosetshenziswa kuyo. Enye indlela iqala ngokukhipha ishidi lensimbi elincanyana kakhulu nokusika imiphetho emincane kakhulu onqenqemeni. Umphetho uyasikwa futhi umphumela uba izikwele eziningi ezincane noma ama-platelet ensimbi. Enye indlela yokwenza okusanhlamvu isebenzisa intambo encane kakhulu eboshwe ezungeze i-mandrel encane, njengenaliti. Ikhoyili ibe isisikwa ibe ama-jump rings amancane kakhulu. Lokhu kudala izindandatho ezilingana kakhulu eziholela kuma-granules anosayizi olinganayo. Umgomo uwukwakha izinhlaka eziningi ezinosayizi ofanayo ezinobubanzi obungekho ngaphezu kuka-1 mm.

Ama-platelet ensimbi noma ama-jump rings ambozwe ngempushana yamalahle ukuze avinjwe ukuthi anganamathelani ngesikhathi sokudubula. Iphansi le-crucible limbozwe ungqimba lwamalahle futhi izingcezu zensimbi zifafazwa ngakho ukuze zihlukaniswe ngokulinganayo ngangokunokwenzeka. Lokhu kulandelwa ungqimba olusha lwempushana yamalahle nezinye izingcezu zensimbi kuze kube yilapho i-crucible isigcwele izingxenye ezintathu kwezine. I-crucible ixoshwa kuhhavini noma kuhhavini, futhi izingcezu zensimbi eziyigugu zijika zibe yizimbulunga ezincane ekushiseni okuncibilika kwe-alloy yazo. Lezi zinhlayiya ezisanda kwakhiwa zishiywa ukuze zipholile. Kamuva zihlanzwa emanzini noma, uma kuzosetshenziswa indlela yokuhlanganisa, zifakwe emanzini anosawoti.

Ama-granules osayizi abangalingani ngeke akhiqize umklamo ojabulisayo. Njengoba kungenakwenzeka ngomkhandi wegolide ukudala ama-sphere afane ngokuphelele anobubanzi obufana ncamashi, ama-granules kufanele ahlungwe ngaphambi kokusetshenziswa. Uchungechunge lwezisefo lusetshenziselwa ukuhlunga ama-granules.

Ulenza kanjani isibhamu segolide?

Ingabe inqubo yokwenza igolide idubula ivele ithulule igolide elincibilikisiwe kancane kancane emanzini ngemva kokulishisa? Noma wenza konke ngesikhathi esisodwa? Whats the purpose of making gold shot instead of ingots ect.

Ukudubula kwegolide akudalwa ukuthululwa kusuka emlonyeni wesitsha. Kufanele ikhishwe nge-nozzle. Ungenza elula ngokubhoboza imbobo encane (1/8") ngaphansi kwesitsha esincibilikayo, ebesizobe sigxunyekwa phezu kwesitsha sakho samanzi, kube nethoshi elidlala esitsheni, lizungeze umgodi. Lokho kuvimbela igolide ekuqandisweni endishini lapho lidluliswa lisuka esitsheni esincibilika kuso impushana yegolide encibilika ngenxa yezizathu ebezilokhu zilukhuni kimina ukuziqonda, ezidala ukudubuleka, esikhundleni sama-cornflakes.

Ukudubula kukhethwa yilabo abasebenzisa igolide, ngoba kwenza ukukala inani elifunekayo kube lula. Abakhandi begolide abahlakaniphile abalincibilikisi igolide eliningi ngesikhathi esisodwa, ngaphandle kwalokho kungaholela ekubunjweni okunesici (ukufakwa kwegesi).

Ngokuncibilikisa inani elidingekayo kuphela, inani elincane elisele (i-sprue) lingancibilika ngenqwaba elandelayo, kuqinisekiswe ukuthi igolide eliphinde lancibilika aliqoqi.

Inkinga ngokuncibilika kwegolide izikhathi eziningi ukuthi isisekelo sensimbi (imvamisa yethusi, kodwa engagcini nje ngethusi) siyayixuba futhi siqale ukudala igesi enqwabelana emaphaketheni amancane ekubunjweni. Iningi lawo wonke ama-jeweler owenza ukulingisa uke waba nalolo lwazi, futhi uvame ukulandisa ukuthi kungani engafuni, noma engancameli ukusebenzisa igolide elike lasetshenziswa ngaphambilini.