Imishini Yokusakaza Eqhubekayo

Umgomo wokusebenza wohlobo olujwayelekile lwemishini yokuphonsa eqhubekayo usekelwe emibonweni efanayo nemishini yethu yokukhipha ingcindezi ye-vacuum. Esikhundleni sokugcwalisa izinto eziwuketshezi eflaskini ungakhiqiza/udwebe ishidi, ucingo, induku, noma ishubhu ngokusebenzisa isikhunta segraphite. Konke lokhu kwenzeka ngaphandle kwamabhamuza omoya noma i-porosity enciphayo. Imishini yokukhipha ivacuum kanye ne-vacuum ephezulu eqhubekayo isetshenziswa ngokuyisisekelo ukwenza izintambo zekhwalithi ephezulu njenge-bonding wire, i-semiconductor, inkambu ye-aerospace.

-

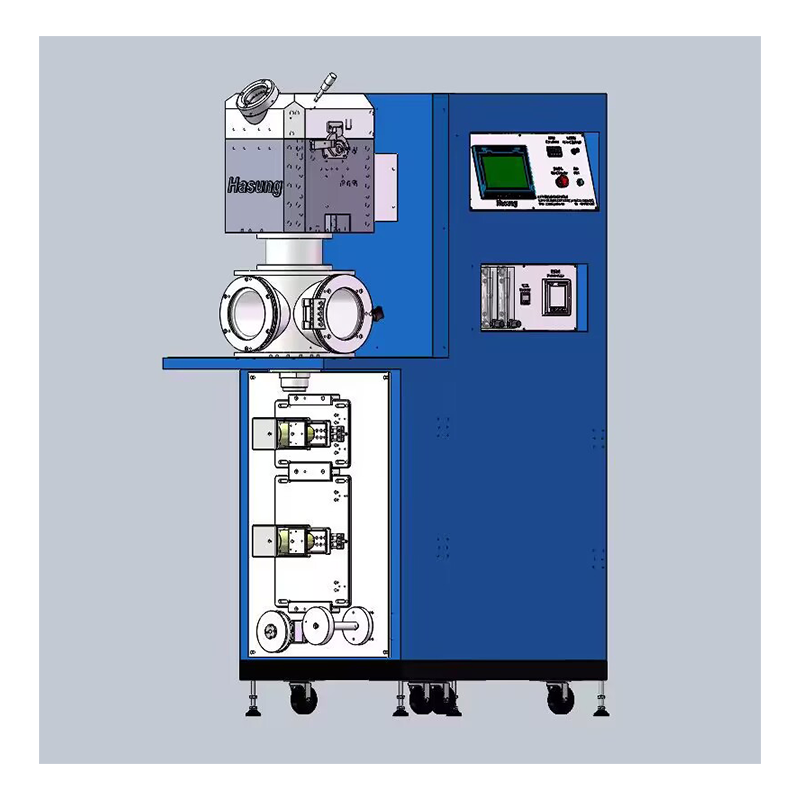

Isisetshenziswa Esiqhubekayo Sokusakaza Se-Hasung-High Vacuum Yezinsimbi Eziyigugu

Izinsimbi ezisebenzayo:izinto zensimbi ezifana negolide, K igolide, isiliva, ithusi, nama-alloys awo

Izimboni zohlelo lokusebenza:izinto zocingo ezibophayo, ukubunjwa kobucwebe, ukucutshungulwa kwensimbi eyigugu, amalabhorethri asenyuvesi kanye nezinye izinkambu ezihlobene

Izinzuzo zomkhiqizo:

1. I-vacuum ephezulu (6.67 × 10-3pa), ukuncibilika kwe-vacuum ephezulu, ukuminyana komkhiqizo ophezulu, okuqukethwe kwe-oxygen ephansi, azikho izimbotshana, ezifanele ukukhiqiza ucingo olubophezelayo olusezingeni eliphezulu;

2. I-Anti oxidation, ukucwengwa kokuvikela igesi ye-inert, ukuxazulula inkinga ye-alloy oxidation;

3. Umbala ofanayo, izindlela zika-electromagnetic kanye nezindlela ezinyakazayo zenza umbala we-alloy ufane kakhulu;

4. Umkhiqizo oqediwe unendawo ebushelelezi futhi wamukela umklamo wokudonsela phansi. Isondo lokudonsa liye labhekana nokwelashwa okukhethekile, futhi umkhiqizo ophelile awunawo umonakalo ebusweni kanye nendawo ebushelelezi;

5. Ukulawula izinga lokushisa okunembile ± 1 ℃, kusetshenziswa amamitha okulawula izinga lokushisa angenisiwe kanye nesistimu yokulawula izinga lokushisa ye-PID ehlakaniphile, enomehluko wokushisa ongu-± 1 ℃;

6. Isikrini sokuthinta esinombala ogcwele wamayintshi angu-7, esilungele ukubuka/ukuthinta, isistimu entsha, isixhumi esibonakalayo esilula se-UI, kulula ukuyisebenzisa ngokuthinta okukodwa nje;

7. Ukuvikelwa okuningi, ukuvikelwa okuningi kokuphepha, ukusetshenziswa kwamahhala kokukhathazeka

-

Umshini Wokusakaza Oqhubekayo Wezinsimbi Eziyigugu Ovundlile

I-vacuum evundlile eqhubekayo yomshini wokuphonsa Izinzuzo

1. Thuthukisa ikhwalithi yomkhiqizo

2. Ukulawulwa kwenqubo okuthuthukisiwe

3. Ukukhiqiza Okungeziwe

4. Ukusebenza kahle kwamandla

Izici zomshini wokuphonsa ovundlile we-vacuum oqhubekayo

1. Idizayini yokusakaza evundlile

2. Igumbi leVacuum

3. Uhlelo lokupholisa

4. Uhlelo oluzenzakalelayo nokulawula

5. Umthamo omkhulu wokuncibilika

6. Ikhwalithi enhle yokukhiqiza umkhiqizo

-

Umshini Wokusakaza Oqhubekayo we-Gold Silver Copper Alloy 20kg 30kg 50kg 100kg

1.As soon as isiliva igolide strip wire tube indukuumshini wokuphonsa oqhubekayongoba ubucwebe yethulwa emakethe, ithole impendulo eyakhayo kumakhasimende amaningi, abathi lolu hlobo lomkhiqizo ungakwazi ngempumelelo ukuxazulula izidingo zabo.Ngaphezu kwalokho, umkhiqizo kabanzi Metal Casting.

2.Umshini Wokuphonsa Oqhubekayo Wokwenza Ipayipi Le-Rod Strip ene-20kg 30kg 50kg 100kg uma kuqhathaniswa nemikhiqizo efanayo emakethe, inezinzuzo ezivelele ezingenakuqhathaniswa ngokusebenza, ikhwalithi, ukubukeka, njll., futhi ijabulela idumela elihle emakethe.Hasung ifingqa iziphambeko zemikhiqizo edlule, futhi ngokuqhubekayo ithuthukisa. Ukucaciswa komshini wokuphonsa oqhubekayo wokwenza ipayipi le-Rod Strip ene-20kg 30kg 50kg 100kg kungenziwa ngokwezifiso ngokuya ngezidingo zakho.

-

Umshini Wokusakaza Oqhubekayo Wevacuum Ephezulu Wezinto Ezintsha Zokusakaza I-Bonding Gold Silver Copper Wire

Ukusakaza kwezinto zikagesi ezifana ne-bond alloy silver copper wire kanye ne-high-purity special wire Ukuklanywa kwalolu hlelo lwemishini kusekelwe ezidingweni zangempela zephrojekthi kanye nenqubo, futhi busebenzisa ngokugcwele ubuchwepheshe besimanje bobuchwepheshe obuphezulu.

1. Yamukela ubuchwepheshe bokushisisa be-high-frequency yaseJalimane, ukulandelela imvamisa okuzenzakalelayo kanye nobuchwepheshe bokuvikela okuningi, obungancibilika ngesikhathi esifushane, bonge amandla futhi busebenze kahle.

2. Uhlobo oluvaliwe + igumbi elincibilikayo lokuvikela igesi elingenasici lingavimbela i-oxidation yezinto ezingavuthiwe ezincibilikisiwe kanye nokuxutshwa kokungcola. Lo mshini ulungele ukuphonswa kwezinto zensimbi ezihlanzeke kakhulu noma izinsimbi ezisetshenziswa kalula nge-oxidized.

3. Sebenzisa igesi evaliwe + engasebenzi ukuze uvikele igumbi elincibilikayo. Lapho incibilika endaweni yegesi engasebenzi, ukulahleka kwe-oxidation yesikhunta sekhabhoni cishe kucishe kungabi nandaba.

4. Ngomsebenzi wokunyakaziswa kwe-electromagnetic + ukunyakazisa kwemishini ngaphansi kokuvikelwa kwegesi ye-inert, akukho ukuhlukaniswa kombala.

5. Ukusebenzisa i-Mistake Proofing (anti-fool) uhlelo lokulawula okuzenzakalelayo, ukusebenza kulula kakhulu.

6. Ngokusebenzisa uhlelo lokulawula izinga lokushisa le-PID, izinga lokushisa linembe kakhulu (±1°C).

7. Uchungechunge lwemishini yokusakaza ye-vacuum ephezulu ye-vacuum eqhubekayo ithuthukiswa ngokuzimela futhi yenziwe, ngobuchwepheshe obuthuthukisiwe, esetshenziselwa ukusakaza okuqhubekayo kwegolide elimsulwa, isiliva, ithusi namanye ama-alloys.

8. Le mishini isebenzisa uhlelo lokulawula uhlelo lwe-Mitsubishi PLC, i-SMC pneumatic kanye ne-Panasonic servo motor drive kanye nezinye izingxenye zomkhiqizo wasekhaya nezangaphandle.

9. Ukuncibilika endaweni encibilikayo yokuvikela igesi e-inert evaliwe, ukuphakela kabili, ukugqugquzelwa kwe-electromagnetic, ukugubha ngomshini, isiqandisi, ukuze umkhiqizo ube nezici zokungabi ne-oxidation, ukulahlekelwa okuphansi, akukho porosity, akukho ukuhlukaniswa kombala, nokubukeka okuhle.

10. Uhlobo lweVacuum: Ivacuum ephezulu.

-

Vacuum Umshini Wokusakaza Oqhubekayo we-Gold Silver Copper Alloy

Isistimu yokusakaza ye-vacuum eqhubekayo

Ngekhwalithi ephezulu kakhulu yezinto eziqedwe kancane:

Ukunciphisa ingozi ye-oxidation ngesikhathi sokuncibilika nangesikhathi sokudweba, sigxila ekugwemeni ukuthintana komoya-mpilo kanye nokwehliswa ngokushesha kwezinga lokushisa lensimbi edwetshiwe.

Izici zokugwema ukuthintana komoyampilo:

1. Isistimu yegesi engasebenzi yegumbi elincibilikayo

2. Uhlelo lwe-vacuum lwegumbi elincibilikayo - lutholakala ngokukhethekile kumishini yokukhipha i-Hasung vacuum eqhubekayo (uchungechunge lwe-VCC)

3. Igesi engasebenzi edonsa idayisi

4. Isilinganiso sezinga lokushisa elibonakalayo

5. Isistimu yokupholisa yesibili eyengeziwe

6. Zonke lezi zinyathelo zifanelekile ikakhulukazi kuma-alloys aqukethe ithusi njengegolide elibomvu noma isiliva njengoba lezi zinto zivame uku-oxidise kalula.Inqubo yokudweba nesimo kungabhekwa kalula ngokubheka amafasitela.

Amadigri evacuum angaba ngokwesicelo samakhasimende.

-

Umshini Wokusakaza Oqhubekayo we-Gold Silver Copper Alloy

Ukuklanywa kwalolu hlelo lwemishini kusekelwe ezidingweni zangempela zephrojekthi kanye nenqubo, kusetshenziswa ubuchwepheshe besimanje bobuchwepheshe obuphezulu.

1. Ngokusebenzisa ubuchwepheshe bokushisisa be-high-frequency yaseJalimane, ukulandelela imvamisa okuzenzakalelayo kanye nobuchwepheshe bokuvikela okuningi, ingancibilika ngesikhathi esifushane, ukonga amandla nokuvikelwa kwemvelo, kanye nokusebenza kahle okuphezulu.

2. Uhlobo oluvaliwe + igumbi elincibilikayo lokuvikela igesi elingenayo lingavimbela i-oxidation yezinto zokusetshenziswa ezincibilikisiwe futhi kuvimbele ukuxutshwa kokungcola. Lo mshini ulungele ukuphonswa kwezinto zensimbi ezihlanzeke kakhulu noma izinsimbi ezisetshenziswa kalula nge-oxidized.

3. Ukusebenzisa igumbi elincibilikisayo lokuvikela igesi elivaliwe + le-inert, ukuncibilika nokuhlanza kwenziwa ngesikhathi esifanayo, isikhathi sincishiswa ngesigamu, futhi ukusebenza kahle kokukhiqiza kuthuthukiswa kakhulu.

4. Ukuncibilika endaweni yegesi ye-inert, ukulahlekelwa kwe-oxidation ye-carbon crucible cishe akunakwa.

5. Ngomsebenzi wokunyakazisa kazibuthe ngaphansi kokuvikelwa kwegesi ye-inert, akukho ukuhlukaniswa kombala.

6. Isebenzisa uhlelo lokulawula i-Mistake Proofing (anti-fool), okulula ukulusebenzisa.

7. Ngokusebenzisa uhlelo lokulawula izinga lokushisa le-PID, izinga lokushisa linembe kakhulu (±1°C). Uchungechunge lwe-HS-CC imishini yokuphonsa eqhubekayo ithuthukiswa ngokuzimela futhi yenziwe ngobuchwepheshe obuthuthukisiwe futhi inikezelwe ekuncibilikeni nasekubunjweni kwegolide, isiliva, ithusi kanye neminye imichilo yama-alloys, izinduku, amashidi, amapayipi, njll.

8. Le mishini isebenzisa uhlelo lokulawula uhlelo lwe-Mitsubishi PLC, i-SMC pneumatic kanye ne-Panasonic servo motor drive kanye nezinye izingxenye zomkhiqizo ezaziwayo ekhaya naphesheya.

9. Ukuncibilika, ukunyakaziswa kwe-electromagnetic, kanye nesiqandisi endaweni encibilikayo + evaliwe yokuvikela igesi engasebenzi, ukuze umkhiqizo ube nezici zokungabi ne-oxidation, ukulahlekelwa okuphansi, ukungabikho kwama-pores, akukho ukuhlukaniswa kombala, nokubukeka okuhle.

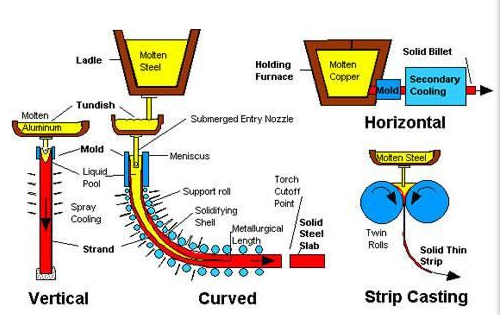

Kuyini ukulingisa okuqhubekayo, kwenziwani, yiziphi izinzuzo?

Inqubo yokuphonsa eqhubekayo iyindlela ephumelela kakhulu yokukhiqiza imikhiqizo ecishe iqedwe njengezigxobo, amaphrofayili, ama-slabs, imicu namashubhu enziwe ngegolide, isiliva nezinsimbi ezingenayo insimbi njengethusi, i-aluminium nama-alloys.

Ngisho noma kunezindlela ezihlukene zokuphonsa eziqhubekayo, awukho umehluko obalulekile ekubunjweni kwegolide, isiliva, ithusi noma ama-alloys. Umehluko obalulekile amazinga okushisa okuphonsa asukela cishe ku-1000 °C endabeni yesiliva noma yethusi ukuya ku-1100 °C uma kuyigolide noma amanye ama-alloys. Insimbi encibilikisiwe ilokhu iphonswa esitsheni sokugcina esibizwa ngokuthi i-ladle futhi igeleza isuka lapho iye endaweni yokubunjwa eqondile noma evundlile enomkhawulo ovulekile. Ngenkathi igeleza phakathi kwesikhunta, esipholiswe nge-crystallizer, isisindo soketshezi sithatha iphrofayili yesikhunta, siqala ukuqina phezulu futhi sishiye isikhunta ku-semi-solid strand. Ngesikhathi esifanayo, ukuncibilika okusha kuhlale kunikezwa esikhunjini ngesilinganiso esifanayo ukuze kuhambisane nentambo eqinisayo eshiya isikhunta. Umucu uphinde upholiswe ngohlelo lokufafaza ngamanzi. Ngokusetshenziswa kokupholisa okuqinisiwe kungenzeka ukwandisa ijubane lokucwebezela futhi kukhiqizwe emugqeni ukwakheka okulinganayo, okusanhlamvu okuhle okunikeza umkhiqizo osuphelile osuphelile izakhiwo ezinhle zobuchwepheshe. Umucu oqinisiwe ube usuqondiswa futhi usikwe ubude obufunayo ngamashekeli noma ithoshi lokusika.

Izigaba zingasetshenzwa ngokuqhubekayo emisebenzini yokugoqa e-in-line elandelayo ukuze kutholwe amabha, izinduku, amabhilidi e-extrusion (izikhala), ama-slabs noma eminye imikhiqizo eqedwe kancane ngobukhulu obuhlukahlukene.

Umlando wokulingisa okuqhubekayo

Imizamo yokuqala yokuphonsa izinsimbi ngenqubo eqhubekayo yenziwa phakathi nekhulu le-19. Ngonyaka we-1857, uSir Henry Bessemer (1813-1898) wathola ilungelo lobunikazi lokuphonsa insimbi phakathi kwama-roller amabili ajikelezayo okwenza ama-slabs ensimbi. Kodwa ngaleso sikhathi le ndlela yahlala inganakwa. Inqubekelaphambili ewujuqu yenziwa kusukela ngo-1930 kuqhubeke kusetshenziswa indlela kaJunghans-Rossi yokusakazwa okuqhubekayo kwezinsimbi ezilula nezisindayo. Mayelana nensimbi, inqubo yokubunjwa eqhubekayo yasungulwa ngo-1950, ngaphambi (nangemva kwalokho) insimbi yathelwa esikhunjeni esinganyakazi ukwenza 'ingots'.

Ukuphonswa okuqhubekayo kwenduku engeyona insimbi kudalwe yinqubo yeProperzi, eyakhiwe ngu-Ilario Properzi (1897-1976), umsunguli wenkampani i-Continuus-Properzi.

Izinzuzo zokulingisa okuqhubekayo

Ukusakaza okuqhubekayo kuyindlela efanelekile yokukhiqiza imikhiqizo engaqediwe yosayizi abade futhi ivumela ukukhiqizwa kwenani elikhulu ngesikhathi esifushane. I-microstructure yemikhiqizo ilinganayo. Uma kuqhathaniswa nokubunjwa kokubunjwa, ukusakaza okuqhubekayo kungokomnotho kakhulu mayelana nokusetshenziswa kwamandla futhi kunciphisa izinsalela ezincane. Ngaphezu kwalokho, izakhiwo zemikhiqizo zingashintshwa kalula ngokushintsha imingcele yokusakaza. Njengoba yonke imisebenzi ingenziwa ngokuzenzakalelayo futhi ilawulwe, ukusakaza okuqhubekayo kunikeza amathuba amaningi okuvumelanisa ukukhiqizwa ngokuguquguqukayo nangokushesha nezimfuneko ezishintshayo zemakethe nokuhlanganisa nobuchwepheshe bedijithali (Industrie 4.0).