Usayizi ohlangene weMetal Granulator Isisetshenziswa Sokuhlanganisa Igolide Lesiliva

Imingcele Yezobuchwepheshe

| Imodeli No. | I-HS-GS2 | I-HS-GS3 | I-HS-GS4 | I-HS-GS5 | I-HS-GS6 | I-HS-GS8 |

| Amandla kagesi | 220V, 50/60Hz, Isigaba esisodwa / 380V, 50/60Hz, 3 Isigaba | |||||

| Amandla | 8KW | 10KW | 15KW | |||

| I-Max Temp | 1500°C | |||||

| Amandla (Igolide) | 2kg | 3kg | 4kg | 5kg | 6kg | 8kg |

| Isikhathi Sokuncibilika | 2-3 amaminithi. | 3-5 imiz. | ||||

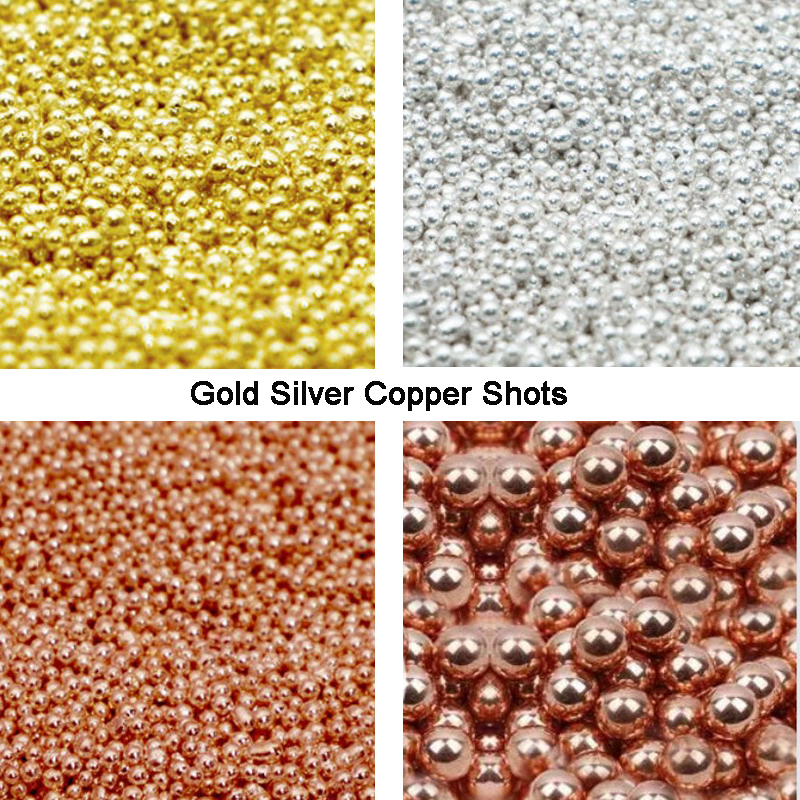

| Isicelo | Igolide, i-K igolide, isiliva, ithusi namanye ama-alloys | |||||

| Ukunikezwa komoya | Umoya we-compressor | |||||

| Ukunemba Kwesikhashana | ±1°C | |||||

| Umtshina wesikhathi | Thermocouple | |||||

| Uhlobo lokupholisa | I-water chiller (ithengiswa ngokwehlukana) noma Amanzi agijimayo | |||||

| Ubukhulu | 1100*930*1240mm | |||||

| Isisindo | Cishe. 180kg | Cishe. 200kg | ||||

Isibonisi somkhiqizo

Isihloko: Indima ye-granulator yensimbi kunqubo yokucwenga igolide

Ukucwenga igolide kuyinqubo ecophelelayo ehilela izigaba eziningi nezinto zokusebenza ukuze kukhishwe igolide elimsulwa esimweni salo esingavuthiwe. Enye yezingcezu zemishini eyinhloko kule nqubo yokucwenga i-granulator yensimbi. Kule bhulogi, sizocubungula indima ye-granulator yensimbi ekucwengeni igolide nokuthi isiza kanjani ekukhipheni igolide elimsulwa.

Iyini i-granulator yensimbi?

Ngaphambi kokuthi singene endimeni ye-granulator yensimbi ekucwengeni igolide, ake siqale siqonde ukuthi iyini i-metal granulator nokuthi isebenza kanjani. I-metal granulator iwumshini oklanyelwe ukuchoboza izinsalela zensimbi zibe yizinhlayiya ezincane, ezinosayizi ofanayo noma ama-granules. Ivamise ukusetshenziswa ezimbonini zokugaywa kabusha nokulawulwa kwemfucuza ukuze kucutshungulwe izinsimbi ezilahliwe futhi ziziguqule zibe yifomu elilawulekayo ukuze kuqhutshekwe nokucutshungulwa.

Indima ye-granulator yensimbi ekucwengeni igolide

Ekucwengisweni kwegolide, imbudumbudu yensimbi idlala indima ebalulekile esigabeni sokuqala sokucutshungulwa kwempahla eluhlaza. Nansi iminikelo yayo kuyo yonke inqubo yokucwenga:

1. Ukuncishiswa kwezinsalela zensimbi

Phakathi nenqubo yokucwenga igolide, kukhiqizwa izinhlobo ezihlukahlukene zemfucumfucu yensimbi, okuhlanganisa izingxenye ezilahliwe, imfucumfucu ye-elekthronikhi nezinye izinto eziqukethe insimbi. Lezi zinto zidinga ukuncishiswa kosayizi ukuze kube lula ukucutshungulwa okuqhubekayo. Lapha yilapho ama-granulator ensimbi engena khona. Ichoboza ngempumelelo izinsalela zensimbi, idale isitoko esilawulekayo sezinyathelo zokucwengisisa ezilandelayo.

2. Ukuhlukaniswa kwezinto ezingezona igolide

Uma izinsalela zensimbi seziguquliwe, isinyathelo esilandelayo senqubo yokucwenga igolide ukuhlukanisa izinto ezingezona igolide nezingxenye ezinegolide. Insimbi eyimbudumbudu ingena ezinqubweni eziqhubekayo zokuhlukanisa ezifana nokuhlukaniswa kazibuthe nokuhlukaniswa okusekelwe ekuminyaneni ukuze kuhlukaniswe into equkethe igolide nayo yonke imfucumfucu yensimbi. Usayizi ofanayo kanye nokuma kwe-granular metal kusiza lezi zindlela zokuhlukanisa, okwenza inqubo isebenze kahle.

3. Thuthukisa indawo engaphezulu ukuze kusetshenziswe amakhemikhali

Ngemva kokuhlukaniswa kwezinto ezingezona igolide, izingxenye eziqukethe igolide eziyimbudumbudu ziphathwa ngamakhemikhali ukuze kukhishwe igolide elimsulwa. Ifomu lezinhlayiya zempahla lihlinzeka ngendawo enkulu engaphezulu, evumela amakhemikhali ukuthi angene futhi asabele nezinhlayiya zegolide ngempumelelo kakhudlwana. Lokhu kuholela ekusebenzeni kahle okuphezulu kwesizinda kanye nenqubo yokucwengisisa.

4. Thuthukisa izinqubo zokuncibilikisa nokuphonsa

Uma igolide selikhishiwe entweni eyimbudumbudu, liphinde licutshungulwe ngokuncibilika kanye nokubunjwa ukuze lenze ama-ingots egolide noma ezinye izimo ezifunwayo. Ifomu eliyimbudumbudu legolide lisiza inqubo yokuncibilika ngoba liyashisa futhi lincibilikise into ngokulinganayo. Lokhu kukhiqiza imikhiqizo yegolide yekhwalithi ephezulu enamazinga angaguquki okuhlanzeka.

Sekukonke, ama-granulator ensimbi adlala indima ebalulekile ezigabeni zokuqala zokucwengwa kwegolide ngokulungisa izinto ezingavuthiwe ukuze ziqhubeke zicutshungulwa, zikhuthaze ukuhlukaniswa okuphumelelayo kwezinto ezingezona igolide, ukwandisa indawo engaphezulu yokucubungula amakhemikhali, kanye nokwenza ngcono izinqubo zokuncibilikisa nokuphonsa.

Ukubaluleka kwezinqubo ezisebenzayo zokucwenga igolide

Inqubo ephumelelayo yokucwenga igolide ibalulekile ekuqinisekiseni ubumsulwa kanye nekhwalithi yomkhiqizo wokugcina wegolide. Kungakhathaliseki ukuthi isetshenziselwa ukwenza ubucwebe, izinjongo zokutshala izimali, noma ukusetshenziswa kwezimboni, igolide elimsulwa laziswa kakhulu futhi liyafunwa. Ngakho-ke, indima yemishini efana ne-pelletizers yensimbi ekucwengeni igolide ekuhlanzekeni nekhwalithi edingekayo ayikwazi ukweqiwa.

Ukwengeza izici zobuchwepheshe, inqubo ephumelelayo yokucwenga igolide nayo inomthelela ekusimameni kwemvelo. Ngokuphatha ngempumelelo kanye nokucubungula udoti wensimbi, okuhlanganisa udoti we-elekthronikhi kanye nezingxenye ezilahliwe, imboni yokucwenga inganciphisa umthelela wemvelo wokumbiwa kwegolide futhi ibe negalelo ekuphathweni kwemithombo esimeme.

Ekuphetheni

Kafushane, ama-granulator ensimbi adlala indima ebalulekile enqubweni yokucwenga igolide, okuhlanganisa ukulungisa izinto ezingavuthiwe, ukwenza kube lula ukuhlukaniswa okuphumelelayo, ukuthuthukisa ukwelashwa kwamakhemikhali, kanye nokwenza ngcono izinqubo zokuncibilikisa nokuphonsa. Igalelo layo ekusebenzeni kahle jikelele kanye nekhwalithi yokucwenga igolide ngeke lishaywe indiva. Njengoba isidingo segolide elimsulwa siqhubeka sikhula, izinqubo zokucwenga ezisebenza kahle, ezisekelwa yimishini ethuthukisiwe njengama-granulator ensimbi, ziya ngokuya zibaluleka ukuze zihlangabezane nezimfuneko zemboni zemikhiqizo yegolide yekhwalithi ephezulu.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur