I-100 mesh - 400 mesh Metal Powder Water Atomizer Machine

Imingcele Yezobuchwepheshe

| Imodeli No. | I-HS-MGA5 | I-HS-MGA10 | I-HS-MGA30 | I-HS-MGA50 | I-HS-MGA100 |

| Amandla kagesi | 380V 3 Izigaba, 50/60Hz | ||||

| Ukunikezwa kwamandla kagesi | 15KW | 30KW | 30KW/50KW | 60KW | |

| Amandla (Au) | 5kg | 10kg | 30kg | 50kg | 100kg |

| I-Max Temp. | 1600°C/2200°C | ||||

| Isikhathi sokuncibilika | 3-5 imiz. | 5-8 imiz. | 5-8 imiz. | 6-10 imiz. | 15-20 imiz. |

| Izinhlamvu zezinhlayiya (Mesh) | 200#-300#-400# | ||||

| Ukunemba Kwesikhashana | ±1°C | ||||

| Iphampu yeVacuum | Iphampu yevacuum yezinga eliphezulu yezinga eliphezulu | ||||

| Isistimu ye-ultrasonic | Ikhwalithi ephezulu ye-Ultrasonic system control system | ||||

| Indlela yokusebenza | Ukusebenza kokhiye owodwa ukuqedela yonke inqubo, uhlelo lwe-POKA YOKE olungenangqondo | ||||

| Isistimu yokulawula | I-Mitsubishi PLC+Isistimu yokulawula ehlakaniphile yomshini womuntu | ||||

| Igesi yangaphakathi | I-nitrogen/Argon | ||||

| Uhlobo lokupholisa | I-water chiller (Ithengiswa ngokwehlukana) | ||||

| Ubukhulu | cishe. 3575*3500*4160mm | ||||

| Isisindo | cishe. 2150kg | cishe. 3000kg | |||

I-Atomization pulverizing method iyinqubo entsha eyakhiwe embonini ye-powder metallurgy eminyakeni yamuva nje. Inezinzuzo zenqubo elula, ubuchwepheshe obulula ukuyiqonda, izinto ezingelula ukuthi zenziwe nge-oxidized, kanye nezinga eliphakeme lokuzenzekelayo.

1. Inqubo ethile yukuthi ngemva kokuba i-alloy (insimbi) incibilikile futhi icwengisiswe esithandweni sokungeniswa, uketshezi lwensimbi oluncibilikisiwe luthululelwa ku-crucible yokulondoloza ukushisa futhi lungene ku-tube yomhlahlandlela kanye nozzle. Ngalesi sikhathi, ukuncibilika kokuncibilika kuvinjwe ukugeleza koketshezi olunomfutho ophezulu (noma ukugeleza kwegesi) Impushana yensimbi ene-athomu ne-athomu iqiniswa futhi ixazululwe embhoshongweni we-atomization, bese iwela kuthangi lokuqoqa impushana ukuze iqoqwe futhi ihlukaniswe. Isetshenziswa kabanzi emkhakheni we-non-ferrous metal powder making njenge-atomized iron powder, i-copper powder, i-stainless steel powder kanye ne-alloy powder. Ubuchwepheshe bokukhiqiza amasethi aphelele emishini yempushana yensimbi, okokusebenza kwempushana yethusi, okokusebenza kwempushana eyisiliva kanye nempahla yempushana yengxubevange kuya ngokuya kuvuthiwe.

2. Ukusetshenziswa kanye nomgomo womshini wokuphalaza we-atomization wamanzi, okokusebenza kokuphonswa kwe-atomization yamanzi kuwumshini oklanyelwe ukuhlangabezana nokukhiqizwa kwenqubo yokuphulula i-atomization yamanzi ngaphansi kwezimo zomoya, futhi iyisisetshenziswa esithuthukisiwe sokukhiqiza ngobuningi. Umgomo wokusebenza wezinto zokuphothula ze-atomization yamanzi ubhekisela ekuncibilikisweni kwensimbi noma ingxubevange yensimbi ngaphansi kwezimo zomoya. Ngaphansi kwesimo sokuvikelwa kwegesi, uketshezi lwensimbi lugeleza ku-tundish yokufaka ukushisa okushisayo kanye nepayipi lokuphambukisa, futhi amanzi anomfutho ophakeme kakhulu ageleza emlonyeni. Uketshezi lwensimbi lune-athomu futhi luqhekeke lube inani elikhulu lamaconsi ensimbi acolisekile, futhi amaconsi amahle akha izinhlayiya eziyisiyingi esingaphansi noma ezingajwayelekile ngaphansi kwesenzo esihlangene sokushuba kwesimo sezulu kanye nokupholisa ngokushesha kwamanzi ngesikhathi sokundiza ukuze kuzuzwe injongo yokugaya.

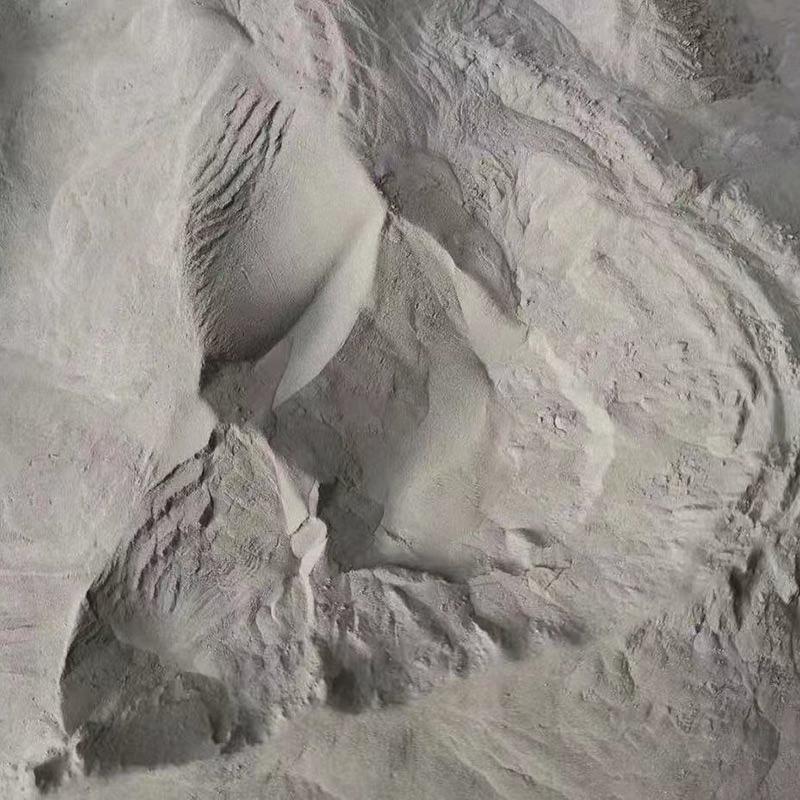

3. Imishini yokugaya i-atomization yamanzi inezici ezilandelayo: 1. Ingakwazi ukulungisa iningi lensimbi kanye ne-alloy powder yayo, futhi izindleko zokukhiqiza ziphansi. 2. I-subspherical powder noma i-powder engavamile ingalungiswa. 3. Ngenxa yokuqina okusheshayo futhi akukho ukuhlukaniswa, ama-alloy powders amaningi akhethekile angalungiswa. 4. Ngokulungisa inqubo efanele, usayizi wezinhlayiyana zempushana ungafinyelela uhla oludingekayo.

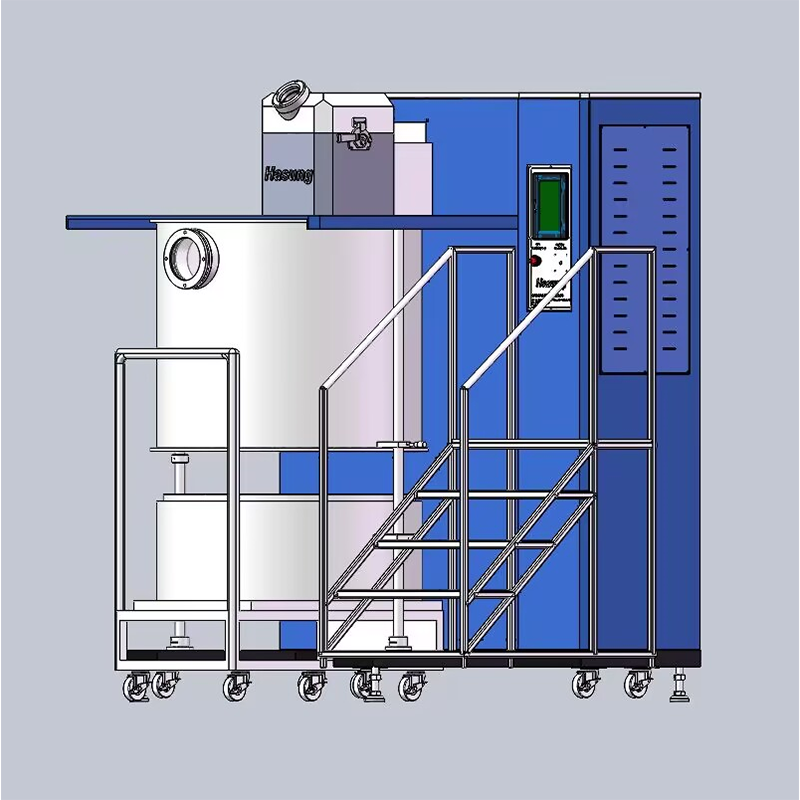

4. Isakhiwo semishini yokuhlikihla i-athomu ye-atomizing yamanzi Isakhiwo semishini yokucwenga amanzi e-atomizing sinezingxenye ezilandelayo: ukuncibilika, uhlelo lwe-tundish, uhlelo lwe-atomization, uhlelo lokuvikela igesi engasebenzi, uhlelo lwamanzi anomfutho ophakeme kakhulu, ukuqoqwa kwempushana, ukomisa amanzi kanye nohlelo lokumisa, uhlelo lokuhlola, uhlelo lwamanzi okupholisa, uhlelo lokulawula lwe-PLC, isistimu yesikhulumi, njll. 1. Uhlelo lokuncibilika kanye ne-tundish: Eqinisweni, luwuhlelo i-intermediate frequency induction melting furnace, ehlanganisa: igobolondo, ikhoyili yokungeniswa, idivayisi yokulinganisa izinga lokushisa, idivayisi yomlilo etshekisayo, i-tundish nezinye izingxenye: igobolondo liyisakhiwo sohlaka, okuyikhabhoni Yenziwe ngensimbi nensimbi engagqwali, kufakwa ikhoyili yokungeniswa. phakathi, futhi i-crucible ifakwe kukhoyili yokungeniswa, engancibilika futhi ithululwe. I-tundish ifakwe ohlelweni lwe-nozzle, esetshenziselwa ukugcina uketshezi lwensimbi encibilikisiwe, futhi inomsebenzi wokulondoloza ukushisa. Incane kune-crucible yesistimu yokuncibilikisa. Isithando somlilo se-tundish sinesistimu yayo yokushisa kanye nesistimu yokulinganisa izinga lokushisa. Isistimu yokushisa yesithando somlilo inezindlela ezimbili: ukushisa kokumelana nokushisa kwe-induction. Izinga lokushisa lokumelana nokushisa lingafinyelela ku-1000 ℃, futhi izinga lokushisa lokungeniswa lingafinyelela ku-1200 ℃ noma ngaphezulu, kodwa impahla ekhiyayo kufanele ikhethwe ngokunengqondo. 2. Uhlelo lwe-atomization: Uhlelo lwe-atomization luqukethe imibhobho, amapayipi amanzi anomfutho ophezulu, ama-valve, njll. 3. Uhlelo lokuvikela igesi engasebenzi: Kunqubo yokuhlikihla, ukuze kwehliswe i-oxidation yezinsimbi nama-alloys kanye nokunciphisa okuqukethwe komoyampilo. wempushana, inani elithile legesi ye-inert ngokuvamile lingeniswa embhoshongweni we-atomization ukuze kuvikelwe umoya. 4. Uhlelo lwamanzi olunomfutho ophezulu wegazi: Lolu hlelo luyidivayisi ehlinzeka ngamanzi anomfutho ophezulu we-atomizing nozzles. Iqukethe amaphampu amanzi anomfutho ophezulu, amathangi amanzi, ama-valve, amapayipi acindezela kakhulu kanye namabhasi. 5. Isistimu yokupholisa: Yonke idivayisi ifakwe ukupholisa amanzi, futhi isistimu yokupholisa ibalulekile. Izinga lokushisa lamanzi okupholisa lizobonakala ethuluzini lesibili ukuze kuqinisekiswe ukusebenza okuphephile kocingo. 6. Uhlelo lokulawula: Uhlelo lokulawula luyisikhungo sokulawula ukusebenza kwedivayisi. Yonke imisebenzi nedatha ehlobene idluliselwa ku-PLC yohlelo, futhi imiphumela iyacutshungulwa, ilondolozwe futhi ikhonjiswe ngokusebenza.

I-R&D kanye nokukhiqizwa kwemishini yobungcweti yokulungisa izinto ezintsha zempushana, ukuhlinzeka ngezixazululo zochungechunge oluchwepheshile zokukhiqiza izinto ezintsha ezithuthukisiwe zempushana, ubuchwepheshe bokulungisa impushana eyindilinga enamalungelo obunikazi obuhlakani obuzimele / ubuchwepheshe bokulungiselela impushana eyisicaba / ubuchwepheshe bokulungiselela impushana / i-flake ubuchwepheshe bokulungiselela i-powder, kanye nobuchwepheshe bokulungiselela i-ultrafine/nano powder, ubuchwepheshe bokulungiselela i-chemical purity purity.

Inqubo Yokwenza I-Metal Powder By Water Atomization Pulverizing Equipment

Inqubo yokwenza impushana yensimbi ngamanzi e-atomization pulverizing imishini inomlando omude. Ezikhathini zasendulo, abantu babethela insimbi encibilikisiwe emanzini ukuze iqhume ibe izinhlayiya zensimbi ezicolekile, ezazisetshenziswa njengezinto zokusetshenziswa ekwenzeni insimbi; kuze kube manje, kusekhona abantu abathela umthofu oncibilikisiwe ngokuqondile emanzini ukuze benze ama-pellets omthofu. . Ukusebenzisa indlela ye-atomization yamanzi ukwenza i-coarse alloy powder, umgomo wenqubo uyafana noketshezi lwensimbi olubalwe ngenhla, kodwa ukusebenza kahle kwe-pulverization kuye kwathuthukiswa kakhulu.

Imishini yokuphehla i-atomization yamanzi yenza i-coarse alloy powder. Okokuqala, igolide elimahhadla liyancibilika esithandweni. Uketshezi lwegolide oluncibilikisiwe kufanele lushiswe ngamadigri angaba ngu-50, bese luthululelwa ku-tundish. Qala iphampu yamanzi anomfutho ophezulu ngaphambi kokuba kujovwe uketshezi olusagolide, bese uvumela idivayisi ye-athomu yamanzi enomfutho ophezulu iqale ucezu lokusebenza. Uketshezi olusagolide ku-tundish ludlula engomeni bese lungena ku-atomizer ngombhobho ovuzayo ongezansi kwe-tundish. I-Atomizer iyisisetshenziswa esibalulekile sokwenza i-coarse gold alloy powder ngenkungu yamanzi enengcindezi ephezulu. Izinga le-atomizer lihlobene nokusebenza kahle kokuchotshozwa kwempushana yensimbi. Ngaphansi kwesenzo samanzi anomfutho ophezulu we-atomizer, uketshezi olusagolide luhlala luhlephuka lube amaconsi amahle, awela oketshezini olupholile ocingweni, bese uketshezi luqina lube yimpushana yengxubevange. Enkambweni yendabuko yokwenza i-powder yensimbi nge-atomization yamanzi e-high-pressure, i-powder yensimbi ingaqoqwa ngokuqhubekayo, kodwa kunesimo sokuthi inani elincane le-powder yensimbi lilahlekile ngamanzi a-atomizing. Enkambweni yokwenza i-alloy powder nge-high-pressure water atomization, umkhiqizo we-athomu ugxiliswa kudivayisi ye-atomization, ngemva kwezulu, ukuhlunga, (uma kunesidingo, ungomiswa, ngokuvamile uthunyelwa ngqo kwinqubo elandelayo.), ukuthola I-alloy powder enhle, akukho ukulahlekelwa kwe-alloy powder kuyo yonke inqubo.

Isethi ephelele yemishini yokucwenga i-atomization yamanzi Izinto zokwakha i-alloy powder ziqukethe lezi zingxenye ezilandelayo:

Ingxenye yokuncibilika:isithando somlilo sensimbi esincibilikisa imvamisa emaphakathi noma isithando somlilo esincibilikisa insimbi esinezinga eliphezulu singakhethwa. Umthamo wesithando somlilo unqunywa ngokusho komthamo wokucubungula we-powder yensimbi, futhi isithando somlilo esingama-50 kg noma isithando somlilo esingama-20 kg singakhethwa.

Ingxenye ye-Atomization:Imishini kule ngxenye iyimishini engeyona ejwayelekile, okufanele yakhelwe futhi ihlelwe ngokuya ngemibandela yendawo yomkhiqizi. Kukhona ikakhulukazi ama-tundishes: lapho i-tundish ikhiqizwa ebusika, idinga ukushiswa; I-Atomizer: I-atomizer izovela kumfutho ophezulu Amanzi anomfutho ophezulu wepompo athinta uketshezi olusagolide olusuka ku-tundish ngesivinini esinqunywe kusengaphambili kanye ne-engeli, aluhlephule lube amaconsi ensimbi. Ngaphansi kwengcindezi yepompo yamanzi efanayo, inani lempushana yensimbi ecolekile ngemva kwe-atomization lihlobene nokusebenza kahle kwe-atomizer ye-atomizer; i-atomization cylinder: indawo lapho i-alloy powder i-atomu, ichotshoziwe, ipholile futhi iqoqwe. Ukuze uvimbele i-ultra-fine alloy powder ku-alloy powder etholiwe ukuthi ingalahleki namanzi, kufanele ishiywe isikhathi esithile ngemva kwe-atomization, bese ifakwa ebhokisini lokuqoqa impushana.

Ingxenye yokucubungula ngemuva:ibhokisi lokuqoqa impushana: lisetshenziselwa ukuqoqa i-athomu ye-alloy powder futhi ihlukanise futhi isuse amanzi amaningi; isithando somlilo: yomisa i-alloy powder emanzi ngamanzi; umshini wokuhlola: hlunga i-alloy powder, Ama-coarser alloy powders angaphandle kokucaciswa angancibilika kabusha futhi enze i-athomu njengempahla yokubuyisela.

I-Vacuum Air Atomization Pulverizing Technology kanye Nokusebenza kwayo

I-powder elungiselelwe i-vacuum air atomization inezinzuzo zokuhlanzeka okuphezulu, okuqukethwe kwe-oxygen ephansi kanye nosayizi wezinhlayiyana zempushana. Ngemva kweminyaka emisha eqhubekayo nokuthuthukiswa, ubuchwepheshe be-vacuum air atomization powder sebuthuthuke baba indlela eyinhloko yokukhiqiza izimpushana zensimbi ezisebenza kahle kakhulu kanye nengxubevange, futhi sekuyisici esiholayo esisekela nokukhuthaza ucwaningo lwezinto ezintsha kanye nokuthuthukiswa kobuchwepheshe obusha. Umhleli wethule isimiso, inqubo kanye nemishini yokugaya impushana ye-vacuum air atomization, futhi wahlaziya izinhlobo nokusetshenziswa kwempushana elungiswe yi-vacuum air atomization.

Indlela ye-atomization iyindlela yokulungisa impushana lapho uketshezi oluhamba ngokushesha (i-atomizing medium) luthinta noma luhlephule uketshezi lwensimbi noma lwengxubevange lube amaconsi amancane, abe esehlanganiswa abe yimpushana eqinile. Izinhlayiya ze-athomu ze-powder azigcini nje ngokuba nokwakheka kwamakhemikhali okufana ncamashi okufanayo ne-alloy encibilikisiwe enikeziwe, kodwa futhi ngenxa yokuqiniswa okusheshayo kuhlanza isakhiwo se-crystalline futhi kuqede i-macrosegregation yesigaba sesibili. I-atomization medium evame ukusetshenziswa ngamanzi noma i-ultrasonic, ebizwa ngokuthi i-atomization yamanzi kanye ne-atomization yegesi ngokufanele. Izimpushana zensimbi ezilungiselelwe yi-atomization yamanzi zinesivuno esikhulu kanye nesivuno esingokomnotho, futhi izinga lokupholisa liyashesha, kodwa ama-powders anokuqukethwe okuphezulu kwe-oxygen kanye ne-morphology engavamile, ngokuvamile ama-flakes. I-powder elungiselelwe ubuchwepheshe be-atomization ye-ultrasonic inobukhulu bezinhlayiyana ezincane, i-sphericity ephezulu kanye nokuqukethwe kwe-oxygen ephansi, futhi isibe indlela eyinhloko yokukhiqiza insimbi eyindilinga esebenza kakhulu kanye nama-alloy powders.

I-vacuum smelting high-pressure gas atomization pulverizing technology ihlanganisa ubuchwepheshe be-vacuum ephezulu, ubuchwepheshe bokuncibilikisa izinga lokushisa eliphezulu, ubuchwepheshe be-high-pressure kanye ne-high-speed gas technology, futhi kukhiqizwa ukuze kuhlangatshezwane nezidingo zokuthuthukiswa kwe-powder metallurgy, ikakhulukazi ukukhiqizwa kwe-high-. ama-alloys ekhwalithi aqukethe izinto ezisebenzayo eziyimpushana. I-Ultrasonic / Gas atomization pulverizing technology ubuchwepheshe obusha bokuqina obusha. Ngenxa yezinga eliphezulu lokupholisa, impushana inezici zokucwenga okusanhlamvu, ukwakheka okufanayo kanye nokuncibilika okuqinile okuphakeme.

Ngaphezu kwezinzuzo ezingenhla, i-powder yensimbi ekhiqizwa i-vacuum smelting i-atomization yegesi ephezulu yokucindezela inezici ezintathu ezilandelayo: i-powder ehlanzekile, okuqukethwe kwe-oxygen ephansi; isivuno esiphezulu se-powder; ukubukeka okuphezulu okuyi-sphericity. Izinto zokwakha noma ezisebenzayo ezenziwe ngale mpushana zinezinzuzo eziningi ngaphezu kwezinto ezivamile ngokwezakhiwo zomzimba namakhemikhali. Izimpushana ezithuthukisiwe zihlanganisa impushana ye-superalloy, i-thermal spray alloy powder, i-copper alloy powder kanye ne-stainless steel powder.

1 Inqubo yokugaya i-vacuum air atomization powder kanye nemishini

1.1 Inqubo yokugaya i-vacuum air atomization powder

Indlela ye-vacuum air atomization pulverizing iwuhlobo olusha lwenqubo olwakhiwe embonini yokukhiqiza impushana yensimbi eminyakeni yamuva nje. Inezinzuzo zokungelula kwe-oxidation yezinto zokwakha, ukucisha ngokushesha kwempushana yensimbi, kanye nezinga eliphakeme lokuzenzakalelayo. Inqubo ethize ukuthi ngemva kokuba ingxubevange (insimbi) incibilikiswe futhi icwengisiswe esithandweni sokungeniswa, uketshezi lwensimbi oluncibilikisiwe luthululelwa ekuwohlokeni kokushisa okushisayo, bese lungena eshubhu lomhlahlandlela kanye nombhobho, futhi ukugeleza kwencibilika ku-athomu yi-high-. ukugeleza kwegesi yokucindezela. Impushana yensimbi ene-athomu iyaqina futhi izinze kumbhoshongo we-athomu, futhi iwela ethangini lokuqoqa impushana.

Imishini ye-atomizing, i-atomizing ultrasonic ne-metal liquid flow yizici ezintathu eziyisisekelo zenqubo ye-atomization yegesi. Emishinini ye-atomization, i-ultrasonic ye-atomizing ejovwe iyashesha futhi ixhumana nokugeleza koketshezi lwensimbi okujovwe ukwenza insimu yokugeleza. Kulo mkhakha wokugeleza, ukugeleza kwensimbi encibilikisiwe kuphukile, kupholiswe futhi kuqiniswe, ngaleyo ndlela kutholwe impushana enezici ezithile. Imingcele yemishini ye-atomization ihlanganisa isakhiwo se-nozzle, isakhiwo se-catheter, indawo ye-catheter, njll., igesi ye-atomization kanye nemingcele yenqubo yayo ihlanganisa izakhiwo ze-ultrasonic, i-air inlet pressure, isivinini somoya, njll., nokugeleza koketshezi lwensimbi kanye nemingcele yenqubo yayo ihlanganisa ukugeleza koketshezi lwensimbi. izakhiwo, ukushisa okuphezulu, ububanzi bokugeleza kwe-liquid, njll. I-atomization ye-Ultrasonic ifinyelela inhloso yokulungisa usayizi wezinhlayiyana ze-powder, ukusatshalaliswa kosayizi wezinhlayiyana kanye ne-microstructure ngokulungisa imingcele ehlukahlukene ukuxhumanisa.

1.2 Imishini yokuhlanza i-athomu ye-vacuum air

Imishini yamanje ye-vacuum atomization pulverizing ikakhulukazi ihlanganisa amathuluzi angaphandle kanye nemishini yasekhaya. Imishini ekhiqizwe phesheya inokuqina okuphezulu kanye nokunemba okuphezulu kokulawula, kodwa izindleko zemishini ziphezulu, futhi izindleko zokuyilungisa nokulungisa ziphezulu. Izindleko zemishini yasekhaya ziphansi, izindleko zokuyilungisa ziphansi, futhi nokunakekela kulula. Kodwa-ke, abakhiqizi bezinto zasekhaya ngokuvamile abanabo ubuchwepheshe obuyisisekelo bemishini efana namabhomu e-atomizing nezinqubo ze-atomization. Njengamanje, izikhungo zocwaningo zakwamanye amazwe ezifanele kanye namabhizinisi okukhiqiza zigcina ubuchwepheshe buyimfihlo kakhulu, futhi imingcele yenqubo ethile neyezimboni ayinakutholwa ezincwadini namalungelo obunikazi afanelekile. Lokhu kwenza isivuno se-powder esezingeni eliphakeme kakhulu sibe phansi kakhulu ukuze sibe ukonga, okuyisizathu esiyinhloko esenza izwe lami lingakwazi ukukhiqiza i-powder ephezulu yezimboni nakuba kunezinyunithi eziningi zokukhiqiza i-aerosol powder kanye namayunithi ocwaningo lwesayensi.

Isakhiwo se-ultrasonic atomization pulverizing device siqukethe lezi zingxenye ezilandelayo: isithando somlilo esincibilikisa imvamisa emaphakathi, isithando somlilo, uhlelo lwe-atomization, ithangi le-atomization, uhlelo lokuqoqa uthuli, uhlelo lokuhlinzeka nge-ultrasonic, uhlelo lokupholisa amanzi, uhlelo lokulawula, njll.

Njengamanje, ucwaningo oluhlukahlukene mayelana ne-aerosolization lugxile kakhulu ezicini ezimbili. Ngakolunye uhlangothi, imingcele yesakhiwo se-nozzle kanye nezici zokugeleza kwejethi ziyafundwa. Inhloso ukuthola ubudlelwano phakathi kwenkundla yokugeleza komoya kanye nesakhiwo se-nozzle, ukuze i-ultrasonic ifinyelele isivinini endaweni yokukhipha umlomo ngenkathi izinga lokugeleza kwe-ultrasonic lincane, futhi linikeza isisekelo sethiyori sokuklama nokucutshungulwa kwe-nozzle. Ngakolunye uhlangothi, ubudlelwano phakathi kwemingcele yenqubo ye-atomization kanye nezakhiwo zempushana zafundwa. Ihlose ukutadisha umphumela wemingcele yenqubo ye-atomization ezimpahleni zempushana kanye nokusebenza kahle kwe-atomization ngesisekelo esiqondile se-nozzle ukuze kuthuthukiswe futhi kuqondise ukukhiqizwa kwempushana. Ngamafuphi, ukuthuthukisa ukukhiqizwa kwempushana enhle nokunciphisa ukusetshenziswa kwegesi kuholela ekuthuthukiseni isiqondiso sobuchwepheshe be-atomization ye-ultrasonic.

1.2.1 Izinhlobo ezahlukahlukene zamanozzles ze-atomization ye-ultrasonic

Igesi ye-atomizing yandisa isivinini namandla ngokusebenzisa umlomo wombhobho, ngaleyo ndlela iphule insimbi ewuketshezi futhi ilungise impushana ehlangabezana nezidingo. I-nozzle ilawula ukugeleza nokugeleza kwephethini ye-atomized medium, futhi idlala indima ebalulekile ezingeni lokusebenza kahle kwe-atomization kanye nokuzinza kwenqubo ye-atomization, futhi iwubuchwepheshe obuyinhloko be-atomization ye-ultrasonic. Enqubweni yokuqala ye-atomization yegesi, isakhiwo se-nozzle esiwa mahhala sasivame ukusetshenziswa. Le nozzle ilula ekwakhiweni, akulula ukuvinjwa, futhi inqubo yokulawula ilula, kodwa ukusebenza kahle kwayo kwe-atomization akuphakeme, futhi kufanelekile kuphela ukukhiqizwa kwempushana ngosayizi wezinhlayiyana ze-50-300 μm. Ukuze kuthuthukiswe ukusebenza kahle kwe-athomu, imibhobho evimbelayo noma imibhobho ye-atomizing ehlanganiswe ngokuqinile iye yenziwa kamuva. Umbhobho oqinile noma ovimbelayo unciphisa ibanga lokundiza kwegesi futhi wehlise ukulahleka kwamandla e-kinetic enqubweni yokugeleza kwegesi, ngaleyo ndlela andise isivinini kanye nokuminyana kokugeleza kwegesi okuhlangana nensimbi, futhi kwandise isivuno sempushana ecolekile.

1.2.1.1 I-Circumferential Slot Nozzle

I-high pressure ultrasonic ingena ku-nozzle tangentially. Bese ikhishwa ngesivinini esikhulu ukuze yenze i-vortex

Ukuze Kuthuthukiswe Ukuphrinta Kwe-3D, I-China Idinga Ukuzakhela Okwayo I-Innovation Chain kanye Nochungechunge Lwezimboni

Eminyakeni emibili edlule, ukuthuthukiswa kwemboni yokukhiqiza okungeziwe kukhuphukele ezingeni likazwelonke lamasu. Amadokhumenti afana ne-"Made in China 2025" kanye "ne-National Additive Manufacturing Industry Action Plan (2015-2016)" akhululiwe. Imboni yokukhiqiza izithasiselo ithuthuke ngokushesha. Ubungqabavu bamabhizinisi asekelwe kubuchwepheshe buyanda. Naphezu kwalokhu, ngoba imboni yokukhiqiza isesigabeni sokuqala sokuthuthukiswa, isabonisa izici zesikali esiphansi. Ochwepheshe bayavuma ukuthi imishini evela kwamanye amazwe manje "ihlasela" imakethe yaseShayina. Ngokuthatha imishini yokunyathelisa yensimbi njengesibonelo, amazwe angaphandle asebenzisa ukuthengiswa okuhlanganisiwe okuhlanganisiwe kwezinto, isofthiwe, okokusebenza kanye nezinqubo. izwe lami kufanele lisheshise ucwaningo nokuthuthukiswa kobuchwepheshe obuyisisekelo kanye nobuchwepheshe bokuqala, futhi lizenzele olwalo uchungechunge lokuqamba izinto ezintsha kanye nochungechunge lwezimboni.

Ithemba lemakethe lihle

Ngokombiko we-McKinsey, ukukhiqiza okungeziwe kukleliswe endaweni yesishiyagalolunye phakathi kobuchwepheshe obuyi-12 obunomthelela ophazamisayo empilweni yomuntu, ngaphambi kwezinto ezintsha negesi ye-shale, futhi kubikezelwa ukuthi ngo-2030 ukukhiqiza okungeziwe kuzofinyelela kusayizi wemakethe olinganiselwa ku-$1 trillion. Ngo-2015, umbiko uqhubekisele phambili le nqubo, uthi ngo-2020, okungukuthi, eminyakeni emithathu kamuva, usayizi wemakethe yokukhiqiza okungeziwe ungafinyelela kunzuzo ye-550 yezigidigidi zamadola aseMelika. Umbiko kaMcKinsey awukhiqizi.

U-Lu Bingheng, isifundiswa se-Chinese Academy of Engineering kanye nomqondisi we-National Additive Manufacturing Innovation Center, usebenzise "okune nesigamu" ukuze afingqe amathemba emakethe esikhathi esizayo okukhiqiza okungeziwe.

Ingxenye engaphezu kwengxenye yenani lomkhiqizo esikhathini esizayo iklanyelwe;

Ngaphezu kwesigamu sokukhiqizwa komkhiqizo kwenziwa ngezifiso;

Ngaphezu kwengxenye yamamodeli okukhiqiza agcwele abantu;

Ngaphezu kwesigamu sezinto ezintsha zenziwa abenzi.

Ukukhiqiza okungeziwe kuwubuchwepheshe obuphazamisayo obuholela ekuthuthukisweni kwemboni yokukhiqiza. Kuwubuchwepheshe obufanele ukusekela ukusungulwa kokuqamba, ukukhiqizwa okwenziwe ngokwezifiso, ukuqamba okusha komenzi kanye nokukhiqizwa kwe-crowdsourcing. "Okubaluleke nakakhulu, ukukhiqiza okungeziwe kuwubuchwepheshe obungavamile obuvumelaniswa nezwe ezweni lami. Njengamanje, ucwaningo lwaseChina mayelana nokunyathelisa kwe-3D luhamba phambili emhlabeni."

U-Lu Bingheng uthe njengamanje, ngokwethembela emshinini omkhulu we-3D wokunyathelisa wensimbi kanye nemishini yokugaya eyakhiwe izwe lami ngokwalo, i-China isesimweni somhlaba wonke ekusetshenzisweni kwezingxenye zezindiza ezinkulu ezithwala imithwalo, futhi isebenza njengenhlangano ithimba losizo lokuqala ocwaningweni nasekuthuthukisweni kwezindiza zezempi nezindiza ezinkulu. Ngaphezu kwalokho, izingxenye ezinkulu zesakhiwo se-titanium alloy ziye zasetshenziswa ocwaningweni nasekuthuthukisweni kwegiya lokuhlalisa izindiza kanye ne-C919.

Mayelana nokusetshenziswa, umthamo wezwe lami ofakiwe wemishini yezinga lezimboni ukleliswe endaweni yesine emhlabeni, kodwa imishini edayiswayo yokunyathelisa insimbi isebuthakathaka, futhi incike kakhulu ekuthengisweni kwamanye amazwe. Kodwa-ke, ngokusho kuka-Academician Lu Bingheng, umgomo jikelele wokukhiqiza okungeziwe kwe-China ukufeza umthamo wesibili omkhulu ofakiwe emhlabeni kanye nokukhiqizwa nokuthengiswa kwemishini enkulu kunazo zonke emhlabeni phakathi neminyaka engu-5; kanye nomthamo wesibili omkhulu ofakiwe emhlabeni, amadivayisi abalulekile nobuchwepheshe bangempela, nokuthengiswa kwemishini phakathi neminyaka eyi-10. Zuza "Made in China 2025" ngo-2035.

Ukuthuthukiswa kwezimboni kuyashesha

Idatha ibonisa ukuthi isilinganiso sokukhula esimaphakathi sosayizi wemakethe wokukhiqiza okungeziwe eminyakeni emithathu edlule. Izinga lentuthuko yale mboni eShayina liphezulu kunesilinganiso somhlaba.

Izimpawu: ngokuvamile zibhekisela kulokho okwenziwayo ukulawula izinhlelo ezithile ezivamile ngaphakathi kwekhampasi

Izimpawu, ezifana nalezi: izimpawu zembali notshani, azikho izimpawu zokukhuphuka, njll. Ukwehla, kodwa emkhakheni wesevisi, izinga lokukhula lishesha kakhulu ngenxa yokuthuthukiswa kokuqashelwa kwamakhasimende. "Ikakhulukazi ekucutshungulweni komkhiqizo nasekukhiqizeni, umthamo wethu woku-oda uphindwe kabili." I-Weinan 3D Printing Industry Cultivation Base esiFundazweni sase-Shaanxi, ngokwesekwa uhulumeni wasekhaya, iguqule izinzuzo zobuchwepheshe bokuphrinta be-3D yaba izinzuzo zezimboni futhi yakhuthaza ukuthuthukiswa nokuguqulwa kwezimboni zendabuko. Isimo esijwayelekile sokubona ukuthuthukiswa kweqoqo.

Ukugxila kumqondo wokufukamela wezimboni we-"3D printing +", akukhona nje ukuthuthukisa imboni yokunyathelisa ye-3D, kodwa ukugxila ekukhiqizeni imishini yokunyathelisa ye-3D, ucwaningo nokuthuthukiswa kanye nokukhiqizwa kwezinto zensimbi zokunyathelisa ze-3D, nokuqeqeshwa. yamathalenta agxile ekusetshenzisweni kokuphrinta kwe-3D. Igxilile ezimbonini ezihamba phambili zasendaweni, ezigxile ekusetshenzisweni kwezicelo zokubonisa imboni yokuphrinta ye-3D, ukusheshisa ukuhlanganiswa kokuphrinta kwe-3D nezimboni zendabuko, nokusebenzisa uchungechunge lwamamodeli e-3D wokuphrinta + wezimboni ezifana nokuphrinta kwe-3D + ukuhamba kwezindiza, imoto, amasiko nokudala, ukusakaza, imfundo, njll., ngosizo lokuphrinta kwe-3D Izinzuzo zobuchwepheshe bokuphrinta, ukuxazulula ubunzima bezobuchwepheshe kanye nezinhlungu zezimboni zendabuko, ukuguqula futhi uthuthukise izimboni zendabuko, futhi wethule futhi ufukamele izinhlobo ezahlukene zamabhizinisi amancane naphakathi nendawo.

Ngokwezibalo, kusukela ngoMeyi 2017, inani lamabhizinisi selifinyelele ku-61, futhi amaphrojekthi angaphezu kuka-50 afana nesikhunta se-3D, i-3D, imishini yezimboni ye-3D, izinto ze-3D, kanye namaphrojekthi we-3D amasiko nokudala agcinwe, okulindeleke ukuthi kwenziwe. Kulindeleke ukuthi ekupheleni konyaka, isibalo samabhizinisi sidlule ku-100.

Ukwenza kusebenze uchungechunge olusha kanye nochungechunge lwezimboni

Naphezu kokuthuthuka okusheshayo kwemboni yezwe lami yokukhiqiza izithasiselo, imboni isesigabeni sokuqala sokuthuthuka futhi isenezici zesikali esiphansi. Kodwa-ke, ukuntuleka kokuvuthwa kwezobuchwepheshe, izindleko eziphezulu zokufaka isicelo, kanye nobubanzi bezicelo obuncane kubangele ukuthi imboni iyonke ibe sesimweni "sokuncane, esihlakazekile futhi esibuthakathaka". Nakuba izinkampani eziningi seziqalile ukubeka unyawo emkhakheni wokukhiqiza okungeziwe, kukhona ukuntuleka kwezinkampani ezihamba phambili I-Driven, isikali semboni sincane. Isazi uLu Bingheng uthe ngokungananaziyo njengobunye bobuchwepheshe obubalulekile benguquko yezimboni yesikhathi esizayo, ukuthuthukiswa kokukhiqiza okungeziwe kufanele kusheshiswe, ngoba ubuchwepheshe bokuphrinta be-3D busesikhathini sokuqhunyiswa kobuchwepheshe, isikhathi sokuqala kwemboni, kanye isikhathi "sokubamba" kwezinkampani. Isidingo esikhulu semakethe singaqhuba ukuthuthukiswa kobuchwepheshe kanye nenkundla yemishini, okufanele ivikelwe futhi isetshenziswe ngokugcwele ukuqondisa nokweseka ukukhiqizwa kwemishini yethu.

Manje imishini evela kwamanye amazwe "ihlasela" imakethe yaseShayina. Ngemishini yokunyathelisa yensimbi, amazwe angaphandle asebenzisa ukuthengiswa okuhlanganisiwe kwezinto, isofthiwe, okokusebenza, nezinqubo. Izinkampani zaseShayina kumele zithuthukise ubuchwepheshe obuyisisekelo kanye nobuchwepheshe bokuqala ukuze zenze ezazo ezintsha kanye namaketanga ezimboni.

Abangaphakathi embonini bathi embonini yamanje yokunyathelisa ye-3D yasekhaya, izinga lokucwaninga nokuthuthukiswa kobuchwepheshe lisetshenziswe ngokuphelele embonini, futhi impumelelo eminingi yezobuchwepheshe isesigabeni selabhorethri kuphela. Izizathu eziyinhloko zale nkinga yilezi: okokuqala, ngenxa yamazinga ahlukahlukene, ukufinyelela Iziqu aziphelele, futhi kunezithiyo ezingabonakali zokungena; okwesibili, izikhungo zocwaningo lwesayensi kanye namabhizinisi abanayo imiphumela esikalini, basesimweni sokulwa wodwa, abanalo ilungelo lokukhuluma ezingxoxweni zezimboni, futhi basesimweni esingesihle; Imboni entsha ayiqondwa kahle, futhi kukhona izindida noma ukungaqondi kahle, okuholela ekuhambeni kancane kokusetshenziswa kobuchwepheshe.

Ithrendi Yokuthuthukiswa Kwezisetshenziswa Ze-Atomization Pulverizing Esikhathini Esizayo

Kusenezingqinamba eziningi ekuqondeni ubuchwepheshe bokuphrinta be-3D kuzo zonke izici zomkhakha wokukhiqiza waseShayina. Uma sibheka isimo sangempela sokuthuthukiswa, kuze kube manje ukuphrinta kwe-3D akukafinyeleli ekuthuthukisweni kwezimboni ezivuthiwe, kusukela kumishini kuya emikhiqizweni kuya ezinsizeni ezisesigabeni "sethoyizi elithuthukisiwe". Nokho, kusukela kuhulumeni kuya kumabhizinisi e-China, amathemba okuthuthukiswa kobuchwepheshe bokunyathelisa be-3D ngokuvamile aqashelwa, futhi uhulumeni kanye nomphakathi ngokuvamile banaka umthelela wesikhathi esizayo we-3D yokunyathelisa yensimbi ye-atomization ye-pulverizing imishini yobuchwepheshe ekukhiqizeni okukhona kwezwe lami, umnotho, namamodeli wokukhiqiza.

Ngokusho kwedatha yocwaningo, okwamanje, isidingo sezwe lami sobuchwepheshe bokuphrinta be-3D asigxiliwe kumishini, kodwa sibonakala ezinhlobonhlobo zezinto ezisetshenziswayo zokuphrinta ze-3D kanye nesidingo sezinsizakalo zokucubungula i-ejensi. Amakhasimende ezimboni angamandla amakhulu ekuthengeni imishini yokuphrinta ye-3D ezweni lami. Imishini abayithengayo isetshenziswa kakhulu kwezokundiza, i-aerospace, imikhiqizo ye-elekthronikhi, ezokuthutha, ukuklama, ukusungula amasiko nezinye izimboni. Njengamanje, umthamo ofakiwe wamaphrinta we-3D emabhizinisini aseShayina cishe u-500, futhi izinga lokukhula lonyaka lingaba ngu-60%. Noma kunjalo, usayizi wemakethe wamanje ungama-yuan ayizigidi eziyi-100 kuphela ngonyaka. Isidingo esingaba khona se-R&D kanye nokukhiqizwa kwezinto zokuphrinta ze-3D sesifinyelele cishe kumayuan ayizigidi eziyizinkulungwane eziyi-1 ngonyaka. Ngokuthandwa nokuthuthuka kobuchwepheshe bemishini, isikali sizokhula ngokushesha. Ngasikhathi sinye, izinsiza zokucubungula eziphathelene nokuphrinta ze-3D zithandwa kakhulu, futhi ama-ejenti amaningi aphrinta i-3D Inkampani yezisetshenziswa ivuthwe kakhulu enqubeni ye-laser sintering kanye nokusetshenziswa kwemishini, futhi ingahlinzeka ngezinsizakalo zokucubungula zangaphandle. Njengoba intengo yesisetshenziswa esisodwa ngokuvamile ingaphezu kwama-yuan ayizigidi ezingu-5, ukwamukelwa kwemakethe akuphakeme, kodwa insizakalo yokucubungula i-ejensi ithandwa kakhulu.

Iningi lezinto ezisetshenziswa emishinini yezwe yami yokuphrinta ye-3D yensimbi yokunyathelisa i-atomization ihlinzekwa ngokuqondile ngabakhiqizi be-prototyping abasheshayo, futhi ukunikezwa okuvela eceleni kwezinto ezijwayelekile akukakaqaliswa, okuholela ezindlekweni zezinto ezibonakalayo eziphakeme kakhulu. Ngesikhathi esifanayo, alukho ucwaningo mayelana nokulungiswa kwempushana okunikezelwe ekunyatheliseni kwe-3D e-China, futhi kunezidingo eziqinile mayelana nokusabalalisa usayizi wezinhlayiyana kanye nokuqukethwe komoya-mpilo. Amanye amayunithi asebenzisa impushana yesifutho evamile esikhundleni salokho, enokungasebenzi okuningi.

Ukuthuthukiswa nokukhiqizwa kwezinto ezisebenza ngezindlela eziningi kuyisihluthulelo sentuthuko yezobuchwepheshe. Ukuxazulula izinkinga zokusebenza nezindleko zezinto zokwakha kuzothuthukisa kangcono ukuthuthukiswa kobuchwepheshe bokwenza ama-prototyping ngokushesha e-China. Njengamanje, izinto eziningi ezisetshenziswa kubuchwepheshe bezwe lami bokuphrinta be-3D bokuphrinta ngokushesha zidinga ukungeniswa zivela phesheya, noma abakhiqizi bemishini batshale amandla amaningi kanye nezimali zokuzithuthukisa, ezibizayo, okuholela ekwenyukeni kwezindleko zokukhiqiza, ngenkathi izinto zasekhaya ezisetshenziswa kulo mshini zinamandla aphansi nokunemba. . Ukwenziwa kwasendaweni kwezinto zokuphrinta ze-3D kubalulekile.

I-Titanium ne-titanium alloy powders noma izimpushana ze-nickel-based superalloy ezisekelwe ku-cobalt ezinokuqukethwe okuphansi kwe-oxygen, usayizi wezinhlayiya ezinhle kanye ne-sphericity ephezulu kuyadingeka. Usayizi wezinhlayiyana ze-powder ngokuyinhloko -500 mesh, okuqukethwe kwe-oxygen kufanele kube ngaphansi kuka-0.1%, futhi usayizi wezinhlayiyana ufana Njengamanje, i-high-end alloy powder kanye nemishini yokukhiqiza isathembele kakhulu ekuthengeni kwamanye amazwe. Emazweni angaphandle, izinto zokusetshenziswa kanye nemishini ngokuvamile kuyahlanganiswa futhi kudayiswe ukuze bathole inzuzo eningi. Uma sithatha njengesibonelo impushana esekelwe ku-nickel, izindleko zezinto ezingavuthiwe zingamayuan angu-200/kg, intengo yemikhiqizo yasekhaya ngokuvamile iwu-300-400 yuan/kg, kanti intengo yempushana ethengwa kwamanye amazwe ivamise ukuba ngaphezu kuka-800 yuan/kg.

Isibonelo, umthelela nokuvumelana nezimo kokwakheka kwempushana, okufakiwe kanye nezakhiwo ezibonakalayo kubuchwepheshe obuhlobene bemishini yokugaya i-3D yensimbi yokunyathelisa i-atomization powder. Ngakho-ke, ngenxa yezidingo zokusetshenziswa kokuqukethwe komoyampilo ophansi kanye nosayizi wezinhlayiyana ezincane eziyimpushana, kusadingeka ukwenza umsebenzi wocwaningo njengokwakheka kwe-titanium ne-titanium alloy powder, ubuchwepheshe bokugaya i-atomization powder ye-particle size powder powder, kanye umthelela wezimpawu zempushana ekusebenzeni komkhiqizo. Ngenxa yokulinganiselwa kobuchwepheshe bokugaya e-China, kunzima ukulungisa i-powder-grained powder okwamanje, isivuno se-powder siphansi, futhi okuqukethwe kwe-oxygen nokunye ukungcola kuphezulu. Ngesikhathi senqubo yokusetshenziswa, isimo sokuncibilika kwe-powder sijwayele ukungalingani, okuholela ekuquketheni okuphezulu kwe-oxide inclusions kanye nemikhiqizo ye-denser emkhiqizweni. Izinkinga eziyinhloko zezimpushana ze-alloy zasekhaya zisezingeni lomkhiqizo nokuzinza kweqoqo, okuhlanganisa: ① ukuzinza kwezingxenye zempushana (inombolo yokufaka, ukufana kwezingxenye); ② impushana ngokomzimba Ukuzinza kokusebenza (ukusabalalisa usayizi wezinhlayiyana, i-powder morphology, i-fluidity, isilinganiso esixekethile, njll.); ③ inkinga yesivuno (isivuno esincane sempushana engxenyeni yosayizi wezinhlayiyana ezincane), njll.

Isibonisi somkhiqizo

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur